As an integral part of every motor vehicle, tires hold a critical responsibility for safety, fuel efficiency, and overall vehicle performance. Understanding the basics of tire technology allows users to make informed choices, ensuring optimal tire longevity and vehicle performance. This rich exploration begins with looking into the rudimentary concepts of tire construction. It delves […]

Material Science Engineering is an interdisciplinary field that covers the design, discovery, and processing of materials for various applications. It integrates principles from physics, chemistry, and engineering to understand and manipulate the structure and properties of materials, ranging from nanomaterials and biotechnology to metals and ceramics. Material science engineers solve real-world problems by making materials that make everything better.

How to calculate Corrosion Rate?

The study of the corrosion of metals has been centered on equilibrium conditions and the tendency of metals to corrode, which has been related to the standard electrode potentials of metals. However, corroding systems are not at equilibrium, and thus thermodynamic potentials do not tell us about the rates of corrosion reactions. The kinetics of […]

What is Precipitation Strengthening/Hardening?

Precipitation Strengthening/Hardening is a heat treatment technique used to increase the yield strength of many metal alloys. Especially the malleable metals such as the alloys of aluminum, magnesium, nickel, titanium, and some steels and stainless steels. Precipitation hardening is also called age hardening or particle hardening. Let us discuss more details about What is Precipitation […]

Production of Copper and Copper Alloys

Copper is one of the few metals that can occur in nature in a directly usable metallic form. Copper is a pinkish-orange color metal that is very soft, malleable, and ductile metal with very good thermal and electrical conductivity. The copper (Cu) atomic number is 29 from the periodic table. Let us discuss more details […]

Production of Aluminum and Aluminum Alloys

Aluminum is a silvery-white lightweight metal of main group 13 from the periodic table. It is the most widely used non-ferrous metal. Let us discuss the engineering properties, production, and different alloys of aluminum. Engineering Properties of Aluminum Aluminum possesses a combination of properties that make it an extremely useful engineering material. Aluminum has a […]

What are Alloy Steels?

Alloy steels are developed to overcome the Plain carbon steel limitations and deficiencies. Alloy steels, in general, cost more than plain-carbon steels, but for many applications, they are the only materials that can be used to meet engineering requirements. Let us discuss the alloy steels in detail. As we mentioned that alloy steels are developed […]

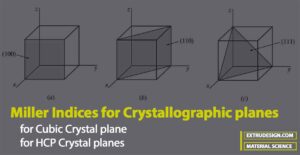

How to calculate Miller Indices for Crystallographic planes?

Sometimes it is necessary to refer to specific lattice planes of atoms within a crystal structure, or it may be of interest to know the crystallographic orientation of a plane or group of planes in a crystal lattice. To identify crystal planes in cubic crystal structures or hexagonal structures, the Miller notation system is used. […]

Production of Iron And Steel

Metals and alloys have many useful engineering properties and so have a widespread application in engineering designs. Iron and its alloys (principally steel) account for about 90% of the world’s production of metals, mainly because of their combination of good strength, toughness, and ductility at a relatively low cost. Each metal has special properties for […]

Principal Metallic Crystal Structures BCC, FCC, and HCP

Most elemental metals about 90% crystallize upon solidification into three densely packed crystal structures. Those are body-centered cubic (BCC), face-centered cubic (FCC), and hexagonal close-packed (HCP). Let us discuss these Principal Metallic Crystal Structures in detail. Important Definitions👉 Crystal: is a solid composed of atoms, ions, or molecules arranged in a pattern that is repetitive […]

What is the Fatigue Crack propagation rate?

Fatigue failure refers to the failure of the machine component due to repeated or cyclic loading. Due to the fluctuation in the stress, this failure occurs. This Fatigue Failure process starts with the Crack initiation due to the repeated cyclic loads. This crack propagates and leads to the Final fatigue failure. This Fatigue failure is […]

How to calculate Fatigue Life?

As we discussed earlier What is fatigue failure. Fatigue failure refers to the failure of the machine component due to repeated or cyclic loading. These cyclic or repeated loads are known as fatigue loads. Due to the fluctuation in the stress, this Fatigue failure occurs. Fatigue life means the number of cycles of stress that a component […]

Engineering Stress and Engineering Strain

In a Machine, every component is subjected to various forces. Due to these forces acting on the machine components, there are various types of stresses are induced. Where a simple stress is defined as the internal resistance force that opposes the external force per unit area. Where the Strain is defined as the deformation per unit […]

What is Creep and Stress Rupture Of Metals?

When a metal or an alloy is under a constant load or stress, it may undergo progressive plastic deformation over a period of time. This time-dependent strain is called creep. The Stress Rupture of Metals referred to the sudden and complete failure of a material under stress when there is a constant loading of the metals. Let us […]

How to calculate Fracture Toughness in metals?

In the previous article, we have discussed the different types of fracture. Ductile fracture and brittle fracture are the broad classifications of fractures. In this article, we will discuss how to calculate Fracture Toughness in metals to avoid failure. As we have discussed in the previous article, ductile fractures may occur in metals due to […]

Ductile Fracture and Brittle Fracture

In material science, Fracture is the separation, or fragmentation, of a solid body into two or more parts under the action of stress. The process of fracture can be considered to be made up of two components, crack initiation and crack propagation. According to the Strain to fracture behavior of metals, there are two types of Fracture in Metals Ductile […]

What are the different types of Fracture in Metals?

In material science, Fracture is the separation, or fragmentation, of a solid body into two or more parts under the action of stress. The process of fracture can be considered to be made up of two components, crack initiation and crack propagation. Let us discuss the Fracture in more detail and list different types of fracture in metals. Types of […]

Common Types of Failure Modes in Material Science

Failure is one of the most important things that every design engineer must deal with. All the structural members and machine elements can fail to perform their intended functions. In order to understand any failure of a machine element first, we need to understand how many possible ways that a machine element can fail. Let […]

How Vicker’s Hardness Test is conducted?

The ability of a material to resist indentation or penetration is called Hardness. To test the hardness of any material is simply forcing an indentor into the surface of the metal by applying the load. There are different methods are developed to test this hardness. In the previous article we have discussed The Brinell Hardness test, the Rockwell Hardness […]

How Rockwell Hardness Test is conducted?

The ability of a material to resist indentation or penetration is called Hardness. To test the hardness of any material is simply forcing an indentor into the surface of the metal by applying the load. There are different methods are developed to test this hardness. In the previous article we have discussed The Brinell Hardness test, this article, […]

How Brinell Hardness Test is conducted?

The ability of a material to resist indentation or penetration is called Hardness. To test the hardness of any material is simply forcing an indentor into the surface of the metal by applying the load. There are different methods are developed to test this hardness. In this article, we are going to discuss one of the […]