Have you ever used the foot pump for your car to inflate the tyre? Yes right there you can see the Foot Pump lever that you press with your foot to inflate your tire. That Foot Lever is nothing but a Mechanical Lever. A Mechanical Lever is a rigid rod or bar capable of turning about a fixed point called a fulcrum. It is used as a machine to lift a load by the application of a small effort. In the previous article, we discuss how to design a Hand lever (Handbrake), in a similar way we will design the Foot lever in this article, not exactly for the Foot pump but for the general design of a Foot lever.

History of Lever

In ancient Egypt circa 4400 BC, a foot pedal was used for the earliest horizontal frame loom. Another device that used the principle of the lever was the swape, or shaduf, a long lever pivoted near one end with a platform or water container hanging from the short arm and counterweights attached to the long arm. This device was used in Egypt and India for raising water and lifting soldiers over battlements as early as 1500 BC.

A balance beam for weighing, consisting of a bar pivoted at its centre and weights that were hung on one end to balance the object being weighed on the other end, was probably used in Egypt around 5000 BC.

Introduction to Lever

A lever is a rigid rod or bar capable of turning about a fixed point called a fulcrum. It is used as a machine to lift a load by the application of a small effort. The ratio of load lifted to the effort applied is called Mechanical Advantage.

Sometimes, a lever is merely used to facilitate the application of force in a desired direction. A lever may be straight or curved and the forces applied on the lever (or by the lever) may be parallel or inclined to one another. The principle on which the lever works is the same as that of moments.

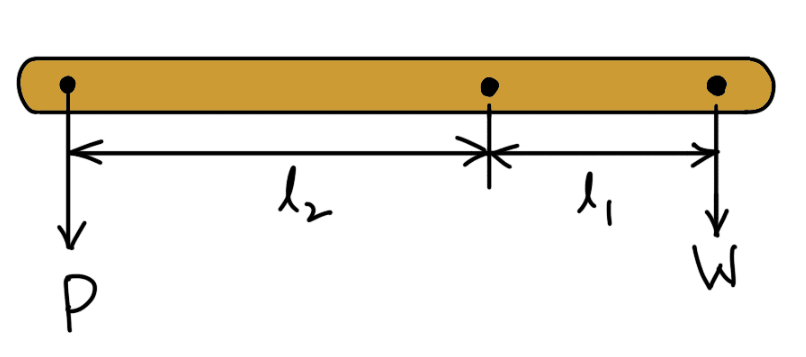

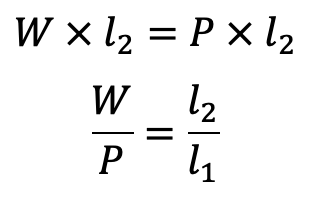

Consider a straight lever with parallel forces acting in the same plane as shown in the following figure.

- The points A and B through which the load and effort are applied are known as load and effort points respectively.

- F is the fulcrum about which the lever is capable of turning.

- The perpendicular distance between the load point and fulcrum (l1) is known as the load arm.

- The perpendicular distance between the effort point and fulcrum (l2) is called the effort arm.

According to the principle of moments,

Mechanical Advantage

The ratio of the effort arm to the load arm i.e. l2 / l1 is called leverage.

A little consideration will show that if a large load is to be lifted by a small effort, then the effort arm should be much greater than the load arm. In some cases, it may not be possible to provide a lever with a large effort arm due to space limitations.

Therefore in order to obtain great leverage, compound levers may be used. The compound levers may be made of straight pieces, which may be attached to one another with pin joints. The bell-cranked levers may be used instead of a number of jointed levers. In a compound lever, the leverage is the product of leverages of various levers.

Foot Lever

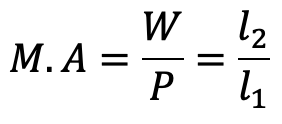

In designing the foot lever, we will follow a similar approach that we did for the design of the Hand lever that we discussed in the previous article. In the Foot lever, a footplate is provided instead of the handle. For foot levers, about 800N is considered the full force that a man can exert in pushing a foot lever. The proportions of the footplate are shown in the following figure.

We are going to design a foot lever of 1m from the center of the shaft to the point of application of 800 N load. We will calculate the diameter of the shaft, the Dimensions of the key, and the dimensions of the rectangular arm of the foot lever at 60 mm from the center of the shaft assuming the width of the arm is 3 times the thickness. We will consider the allowable tensile stress may be taken as 73 MPa and the allowable shear stress as 70 MPa.

length of the lever L = 1 m = 1000 mm

Load P = 800 N ;

Allowable tensile stress σt = 73 MPa = 73 N/mm2;

Allowable shear stress τ = 70 MPa = 70 N/mm2

Diameter of the shaft

Let

d = Diameter of the shaft.

We know that the twisting moment on the shaft,

T = P × L = 800 × 1000 = 800 × 103 N-mm

We also know that the twisting moment on the shaft (T),

800 × 103 = π/16 ×τ × d3

800 × 103 = 13.75 d3

d3 = 800 × 103 / 13.75

d3 = 58.2 × 103

d = 38.8

We know that the diameter of the boss,

d2 = 1.6 d

d2 = 1.6 × 40

d2 = 64 mm

The thickness of the boss,

t2 = 0.3 d

t2 = 0.3 × 40

t2 = 12 mm

The length of the boss, l2 = 1.25 d = 1.25 × 40 = 50 mm

Now considering the shaft under combined bending and twisting, the diameter of the shaft at the centre of the bearing (d1) is given by the relation

π /16 × τ(d1)3= p √(l2+L2)

π /16 × 70 × (d1)3 = 800 √((100)2 +(1000)2)

13.75 (d1)3 = 804 × 103

(d1)3 = 804 × 103 / 13.75

(d1)3 = 58.5 × 103

d1 = 38.8

Let us take the Diameter of the shaft as 40mm.

Dimensions of the key

The standard dimensions of the key for a 40 mm diameter shaft are :

Width of key, w = 12 mm

the thickness of key = 8 mm

The length of the key (l1) is obtained by considering the shearing of the key.

We know that twisting moment (T),

800 × 103 = l1 × w × τ × d/2

800 × 103 = l1 ×12 ×70 ×40/2=16 800 l1

l1 = 800 × 103 / 16800

l1 = 47.6 mm

It may be taken as equal to the length of the boss (l2).

∴ l1 = l2 = 50 mm

Dimensions of the rectangular arm at 60 mm from the centre of the shaft

Let

t = Thickness of arm in mm

B = Width of the arm in mm = 3t

∴ The bending moment at 60 mm from the centre of the shaft,

M = 800 (1000 – 60)

M = 752 × 103 N-mm

Z = 1/6 × t × B2

Z = 1/6 × t(3t)2

Z = 1.5 t3 mm3

We know that the tensile bending stress (σt),

73 = M/Z

73 = 752 × 103 / 1.5 t3

73 = 501.3 × 103 / t3

t3 = 501.3 × 103 / 73

t3 = 6.87 × 103

t = 19

Let us take the Thickness of the arm as 20mm.

The Width of the arm is B = 3t = 3 × 20 = 60 mm

The width of the arm is tapered while the thickness is kept constant throughout. The width of the arm on the footplate side will be B1 = B / 2 = 30 mm.

This is all about food lever design. Additionally, we have already discussed different mechanical lever designs in the following articles. Check it out.

- Hand Lever (Hand Brake)

- Cranked Lever (Hoisting Winches)

- Lever Safety Valve

- Bell Crank Lever

- Rocker Arm for Exhaust Valve

Let us know what you think about this article in the comment section below.

Leave a Reply