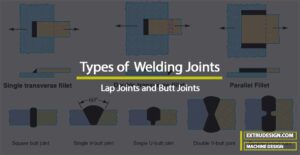

In the previous article, we have discussed different types of welding methods such as TIG welding, MIG welding, Arc welding, and Gas welding. All these welding methods are done on the two base metals to permanently fasten them together to withstand the applicable loads. choosing the best welding joint is also a crucial task for welder. In this […]

In Mechanical Engineering, Machine Design is subjected to creating new or Advanced machines. This involves improving the existing machines to better machines.

The design process is a time-consuming process which includes implementing an Idea and considering the commercial and economic aspects, Making the idea into a shape in the form of drawings by keeping the available resources in mind to make the actual Idea into a life.

How to calculate Welding Joint Strength?

It is very important to know how strong is your welded joint. You have to know how good is your welded joint. Otherwise, the weldment may fail and you will be in big trouble. To make sure if the welding joint is capable of having enough strength to withstand your applied load you have to […]

TIG Welding vs MIG welding

We have discussed the TIG welding and the MIG welding processes in the previous article. Now it’s time to compare the major differences between these two processes to differentiate the use of these two distinctive welding processes. One of the common aspects of these welding processes is that they both are Electric arc welding. Under […]

What is MIG Welding Process?

We have been discussing different types of arc welding in the previous article. Yes, this MIG welding is one of the types of Arc welding. The full form of MIG welding is Metal Inert gas Welding. Let us discuss more details such as the MIG welding process, MIG welding used for which applications, and MIG welding […]

What is TIG Welding Process?

We have been discussing different types of arc welding in the previous article. Yes, this TIG welding is one of the types of Arc welding. The full form of TIG welding is Tungsten Inert gas Welding. Let us discuss more details such as the TIG welding process, TIG welding used for which applications, and TIG […]

What are Electric Arc Welding Types?

This Electric Arc welding is the most commonly seen welding process in our life. Yes! the welding that you see in the welding shops to construct the metal gates, vehicle body repairs, and common engineering works. Those are all not the same Electric Arc Welding types. Let us discuss different types of Electric Arc Welding, […]

What are the Gas Welding Types, Flame types, and Equipment?

Gas welding is a fusion type of welding, which uses the flame of an oxy-acetylene or hydrogen gas from a welding torch upon the surfaces of the prepared joint. There are different gas welding types based on the type of gas for the flame we use for the welding. Let us discuss more details about […]

Welding Processes Classification

A welded joint is a permanent joint. This welded joint can be made by the fusion of the edges of the two parts to be joined together, with or without the application of pressure and filler material. Based on this the welding process is classified. In this article, we are going to discuss the Welding Processes […]

Advantages and Disadvantages of Welded Joints over Riveted Joints

In the previous article, we have discussed the riveted Joint, which is a permanent type joint. In this article, we will discuss the different Advantages and Disadvantages of Welded Joints over Riveted Joints. First of all, what is a Welded Joint? Welded Joint A welded joint is a permanent joint. This welded joint can be […]

Failure of Riveted Joints

Have you ever seen the Failure of Riveted joints? That’s right. that is one of the ways it fails. There is shear in the Rivets as per the above failure picture. The following image is a sample of the Failure of a Riveted joint due to the tearing of the plate. So, there are different […]

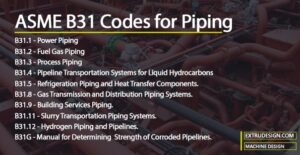

ASME Codes for Piping System

In the previous article, we had an introduction to the piping systems, Piping applications, Piping Material selection, Pipe Joints, Pipe Fittings, and Piping system standards. Among the different Piping standards, One of the most used standards for the piping system is ASME B31. Which regulates the design, material selection, inspection, test, and safety of the […]

Introduction to Piping System | What is piping?

After a few requests from my readers, I am finally writing about the introduction to the Piping system. As we all knew, Pipes are used to transporting fluids, slurries, and sometimes even very fine particles. The most common application we see in the piping is Plumbing in our buildings, workplaces, and many places where water […]

What are the different types of Riveted Joints?

What is a Rivet? Well, A Rivet is a permanent fastening element mostly used for fastening light metals of plates in Boiler shells, structural works, Shipbuilding, and bridges. In the previous article, we have discussed the Riveted joint method, Different Rivethead types, and the materials used for the Rivets according to the Indian Standards. In this article, we are […]

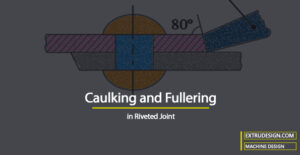

What is Caulking and Fullering in Riveted Joint?

In the previous article, we have discussed the Riveted joint method, Rivethead types, and the materials used for the Rivets according to the Indian Standards. In the Riveting methods, it is essential for some applications to make a leak-proof Riveted joint. Those applications are Boilers, air receiver tanks, and ship hulls. In order to achieve […]

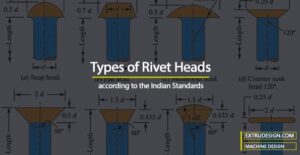

What are the types of Rivet Heads according to the Indian Standards?

What is a Rivet? Well, A Rivet is a permanent fastening element mostly used for fastening light metals of plates in Boiler shells, structural works, Shipbuilding, and bridges. In this article, we are going to discuss different types of Rivet Heads according to the Indian Standards. In a permanent joint, Rivet is the fastening element. […]

Methods of Riveting and Material used for Rivets

What is a Rivet? Well, A Rivet is a permanent fastening element mostly used for fastening light metals of plates in Boiler shells, structural works, Shipbuilding, and bridges. In this article, we are going to discuss the methods of Riveting joints and what are the materials that can be used for the Rivets. In a […]

How to design an Oval Flanged Pipe Joint?

The Oval flanged Pipe Joints are mostly used in small pipes with diameters up to 175mm. This Oval Flanged Pipe Joint is mostly used in Hydraulic applications. In the previous article, we have discussed the Circular Flanged Pipe joint. To design an Oval Flanged Pipe Joint we need to determine the main parameters such as […]

How to design a Circular Flanged Pipe Joint?

The circular flange pipe joint is one of the most used flange joints among the other types of flanged joints. To design such a circular flanged joint we have to determine the main influencing factors and evaluate them. In this article, we will determine the main parameters to design a circular flanged joint for a […]

What Pipe Flange should I use based on Steam pressure according to Indian Boiler Regulation?

Is there any regulation that standardized the pipe diameter and thickness for the steam pressure? Yes, there is a regulation in India called the Indian Boiler Regulation, in short IBR which is created on 15th September 1950 to regularise the manufacturing of boilers, steam generators, and steam distribution piping systems. For the manufacturers and the […]

What are different Pipe Joints?

In transporting fluids such as water, steam, gases, oil, and chemicals, pipes are used. Designing a pipe with basic parameters such as the diameter and thickness of the pipe is explained in the previous article. While designing these pipes the length can be limited, there must be a way to join them to achieve suitable […]

- « Previous Page

- 1

- …

- 4

- 5

- 6

- 7

- 8

- …

- 11

- Next Page »