Torsional Rigidity is simply the resistance to the angular twist of any shaft or beam. But how it is different from Lateral Rigidity? Let us discuss Torsional Rigidity and Lateral Rigidity in detail to understand the differences. In the previous articles, we have been discussing how to design a shaft if it is subjected to […]

In Mechanical Engineering, Machine Design is subjected to creating new or Advanced machines. This involves improving the existing machines to better machines.

The design process is a time-consuming process which includes implementing an Idea and considering the commercial and economic aspects, Making the idea into a shape in the form of drawings by keeping the available resources in mind to make the actual Idea into a life.

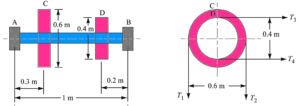

Example Problem on Calculating Shaft Diameter

In the previous articles we have discussed calculating shaft diameter if it is subjected to twisting moment, bending moment, fluctuating, and Axial Load. Following are the list of all the article we have discussed. How to calculate the shaft diameter from the torque? How to calculate Shaft Diameter under Twisting, Bending Moment, and Fluctuating? How […]

How to calculate Shaft Diameter under Twisting and Bending Moment?

In the previous article, we have discussed that from a given torque we can calculate the shaft diameter, but what if the shaft is subjected to the bending moment and twisting at the same time? Let us see how we can calculate shaft diameter under the twisting and bending moment. Design of Shafts The design […]

Turnbuckle: Adjustable Screwed Joint for Round Rods

A turnbuckle is a joint or also known as a coupling to join two threaded rods together. This turnbuckle is also referred to as Rigging screws or an Adjustable Screwed Joint for Round Rods. Let us see how we can design Turnbuckle to connect two threaded rods. Turnbuckle In this adjustable screwed joint, one of […]

Design Calculations of Knuckle Joint

A knuckle joint is a mechanical joint that helps to connect two rods that are under the action of tensile loads. In some cases, it is possible to join the rods with knuckle join if they are under compressive load with proper guided supports. In this article, we will discuss how to calculate the design […]

How to design a Cotter Foundation Bolt?

Topic: Design of a Cotter Foundation bolt A foundation bolt is used to fasten a structure or a machine to a permanent base. Following is an example of an ordinary Foundation Bolt used for the structure to hold on the ground. Cotter Foundation Bolt Cotter Foundation Bolt is a combination of a Cotter with the […]

Designing a Cotter Joint to Connect Piston Rod and Crosshead

We have been discussing the different types of Cotter joint, and in the previous article, we have discussed how to design the Gib and cotter joint for the connecting rod big end with strap. In this article, we are going to design a Cotter joint to connect piston rod and crosshead. Cotter Joint to Connect […]

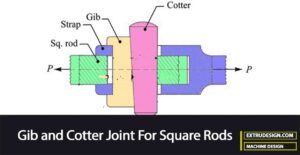

How to Design a Gib and Cotter Joint for Square Rods?

As you know, there are 3 different types of cotter joints. The Gib and Cotter Joint is one of them. The other two are the Socket and Spigot Cotter Joint, and Sleeve and cotter joint. In this article, we are going to discuss how to design the Gib and Cotter joint for Square rods to avoid possible failures […]

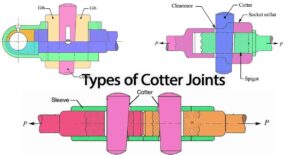

What are the Different Types of Cotter Joint?

A Cotter joint is a joint which is locked by a cotter. A cotter is a flat wedge-shaped piece of rectangular cross-section and its width is tapered from one end to another for an easy adjustment. Mostly it is tapered on one side but sometimes it may be tapered on both sides. Let us see […]

How to design a Gib and Cotter Joint for Connecting Rod end?

As you know, there are 3 different types of cotter joints. The Gib and Cotter Joint is one of them. The other two are the Socket and Spigot Cotter Joint, and Sleeve and cotter joint. In this article, we are going to discuss this Gib and Cotter Joint construction and how to design it for the Connecting […]

How to Design a Sleeve and Cotter Joint?

As you know, there are 3 different types of cotter joints. The Sleeve and Cotter Joint is one of them. The other two are the Socket and Spigot Cotter Joint, and Gib and cotter joint. In this article, we are going to discuss this Sleeve and Cotter joint construction and how to design this Cotter Joint […]

How to design Socket and Spigot Cotter Joint?

As you know, there are 3 different types of cotter joints. The first one is the Socket and Spigot cotter joint. The other two are the Sleeve and cotter joint, and Gib and cotter joint. In this article, we are going to discuss this first type of cotter joint construction and how to design this Socket […]

How to Calculate Eye Bolt Diameter to Lift Load?

A lifting eye bolt, as shown in the below picture, is used for lifting and transporting heavy machines. It consists of a ring of the circular cross-section at the head and is provided with threads at the lower portion for screwing inside a threaded hole on the top of the machine. But how to choose […]

How to Calculate Stress in Bolts?

We have discussed the different types of screw fasteners in the previous article, In every screwed joint these screwed fasteners will be tightened with torque or load which they can withstand. In order to know how much load we can apply, we must understand how much amount of stress it can bear in the screwed […]

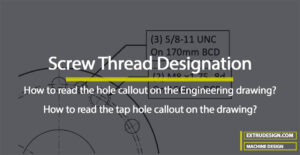

How to Read Screw Thread Designation?

Have you ever wondered how to read the screw thread designation in engineering drawings? Sometimes it’s quite confusing to read the Hole thread designation on the drawings. Let us discuss How to read Screw Thread Designation from the hole or shaft screw thread callout on the engineering drawings. Designation meaning: The act of indicating or […]

Locking Devices for Screwed Joints

Fastening is a process of joining two or more machine elements together to work in a function. There will be two types of fastening. Permanent fastening such as welding, riveting and temporary fastening such as screwed joint. Screws are the temporary fasteners. which means the joining of the machine elements can be disassembled whenever it is required without damage […]

Different Types of Screw Fasteners in Screwed Joint

Fastening is a process of joining two or more machine elements together to work in a function. There will be two types of fastening. Permanent fastening such as welding, riveting and temporary fastening such as screwed joint. Screws are the temporary fasteners. which means the joining of the machine elements can be disassembled whenever it […]

Welding Joint Stresses and Stress Concentration Factors

In the previous article, we have discussed how discussed different welding processes Arc welding TIG welding, MIG welding, Gas welding, also have discussed how to calculate the welding joint strength. Let us discuss welding joint stresses and different stress concentration factors for the Welded joints. Welding Joint Stress Welding joint stresses are difficult to determine […]

What is a Heat Affected Zone in a Welding?

The Heat Affected Zone is an important phenomenon of arc welding, which may result in developing cracks in the welding. so understanding the Heat Affected Zone and its effects is necessary for every welder. In the Arc welding process, as we have already discussed a great amount of heat is generated to produce the weld […]

Mechanical Engineering Standards List

Every Design engineer must know the Engineering standards and codes for the design of the machine element and equipment to achieve Reliability, ensure safety, attain productivity, and efficiency. Let us discuss the different Mechanical Engineering Standards, codes that every engineer should know. Why do Engineers follow the Standards? Every mechanical engineer will work in a […]

- « Previous Page

- 1

- …

- 3

- 4

- 5

- 6

- 7

- …

- 11

- Next Page »