Interferometry is nothing but the use of optical interference to carrying out precise measurements of very small linear dimensions. Laser Interferometer is one of the interferometers which uses laser means and electronic controls to carry out the inspection of machine parts for straightness, parallelism, and flatness, and measurement of very small diameters, among others, and also to Calibrate slip gauges. In this article, we are going to discuss the construction and working principle of the Laser Interferometer.

- Laser-based Interferometers are becoming increasingly popular in metrology applications in recent times.

- Traditionally, lasers were more used by physicists than engineers, since the frequencies of lasers were not stable enough.

- However now, stabilized lasers are used along with powerful electronic controls for various applications in metrology. Gas lasers, with a mixture of neon and helium, provide perfectly monochromatic red light.

- Interference fringes can be observed with a light intensity that is 1000 times more than any other monochromatic light source.

- However, even to this day, laser-based instruments are extremely costly and require many accessories, which hinder their usage.

- More importantly, from the point of view of calibration of slip gauges, one limitation of laser is that it generates only a single wavelength.

- This means that the method of exact fractions cannot be applied for measurement.

- In addition, a laser beam with a small diameter and high degree of collimation has a limited spread.

- Additional optical devices will be required to spread the beam to cover a larger area of the workpieces being measured.

- In interferometry, laser light exhibits properties similar to that of any ‘normal’ light.

- It can be represented by a sine wave whose wavelength is the same for the same colors and amplitude is a measure of the intensity of the laser light.

- From the measurement point of view, laser interferometr can be used for measurements of small diameters as well as large displacements.

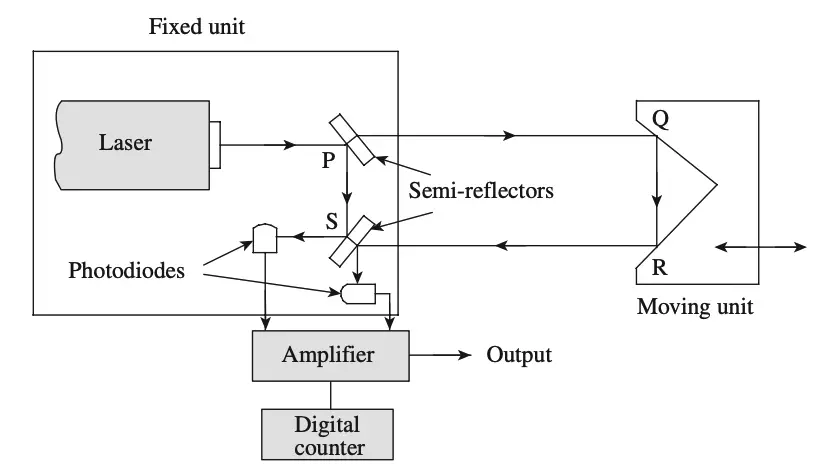

In this section, we present a simple method to measure the latter aspect, which is used for measuring machine slideways. The laser-based instrument a Laser Interferometer is shown below figure.

Construction of Laser Interferometer

- The fixed unit called the laser head consists of a laser, a pair of semi-reflectors, and two photodiodes.

- The sliding unit has a corner cube mounted on it.

- The corner cube is a glass disk whose back surface has three polished faces that are mutually at right angles to each other.

- The corner cube will thus reflect light at an angle of 180°, regardless of the angle at which light is incident on it.

- The photodiodes will electronically measure the fringe intensity and provide an accurate means for measuring displacement.

Working principle of Laser Interferometer

- Laser light first falls on the semi-reflector P, is partially reflected by 90°, and falls on the other reflector S.

- A portion of the light passes through P and strikes the corner cube.

- Light is turned through 180° by the corner cube and recombines at the semi-reflector S.

- If the difference between these two paths of light (PQRS − PS) is an odd number of half wavelengths, then interference will occur at S and the diode output will be at a minimum.

- On the other hand, if the path difference is an even number of half wavelengths, then the photodiodes will register maximum output.

- It must have now become obvious to you that each time the moving slide is displaced by a quarter wavelength, the path difference (i.e., PQRS − PS) becomes half a wavelength and the output from the photodiode also changes from maximum to minimum or vice versa.

- This sinusoidal output from the photodiode is amplified and fed to a high-speed counter, which is calibrated to give the displacement in terms of millimeters.

- The purpose of using a second photodiode is to sense the direction of movement of the slide.

Applications

Laser interferometers are used to calibrate machine tables, slides, and axis movements of coordinate measuring machines. The equipment is portable and provides a very high degree of accuracy and precision.

Conclusion

This is all about the Laser Interferometer, and this laser interferometer is working on the principle of optical interference. And also we have discussed the other types of Interferometers such as the NPL Flatness Interferometer, Pitter–NPL Gauge Interferometer.

Leave a Reply