In material science, Fracture is the separation, or fragmentation, of a solid body into two or more parts under the action of stress. The process of fracture can be considered to be made up of two components, crack initiation and crack propagation. Let us discuss the Fracture in more detail and list different types of fracture in metals.

Types of Fracture in Metals according to Strain to Fracture

As we mentioned Fracture is the separation, or fragmentation, of a solid body into two or more parts under the action of stress. The Fractures can be classified based on different characteristics. First of all, let us classify the Fractur due to strain or we can simply say Strain to fracture.

According to the Strain to fracture, there are two types of Fracture in Metals

- Ductile Fracture

- Brittle Fracture

1. Ductile Fracture

A ductile fracture is characterized by appreciable plastic deformation prior to and during the propagation of the crack.

An appreciable amount of gross deformation is usually present at the fracture surfaces.

Read more about the Ductile fracture here

2. Brittle Fracture

Brittle fracture in metals is characterized by a rapid rate of crack propagation, with no gross deformation and very little micro deformation.

The tendency for a brittle fracture will be increased with decreasing temperature, increasing strain rate, and triaxial stress conditions usually produced by a notch.

Brittle fracture is to be avoided at all costs because it occurs without warning and usually produces disastrous consequences.

Read more about Brittle Fracture here

The boundary between a ductile and brittle fracture is arbitrary and depends on the situation being considered. For example, nodular cast iron is ductile when compared with ordinary gray iron; yet it would be considered brittle when compared with mild steel. As a further example, a deeply notched tensile specimen will exhibit little gross deformation, yet the fracture could occur by a shear mode.

These two fractures are a broad classification. But If we look into the types of tensile fractures which can occur in metals, those are

(a) Brittle Fracture of Single Crystals and polycrystals

(b) Shearing Fracture in Ductile Single Crystals

(c) Completely Ductile Fracture in Polycrystals

(d) Moderate Ductile Fracture in Polycrystals

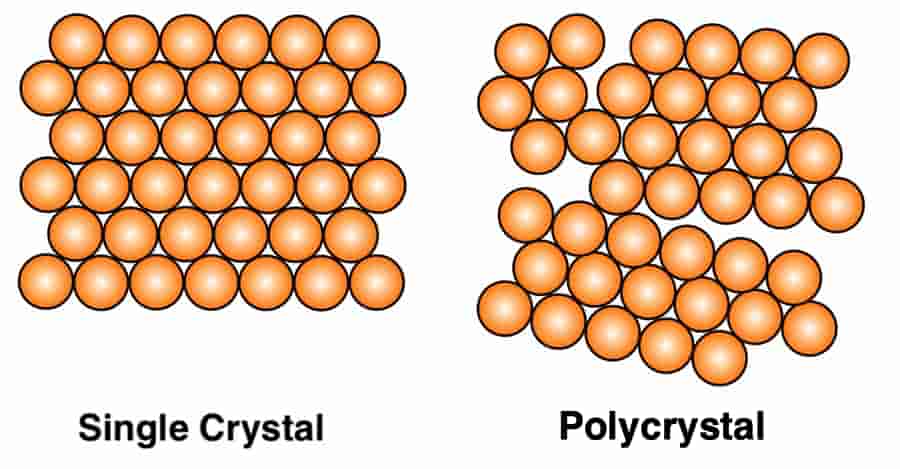

These fractures were observed when they were subjected to tensile loading. Before we discuss these fractures we need to know what is the single crystal and polycrystals.

A single crystal is sometimes called a monocrystal solid in which the crystal lattice of the entire sample is continuous and unbroken to the edges of the sample, with no grain boundaries.

Whereas the polycrystal solids are composed of many crystallites of varying size and orientation separated by grain boundaries.

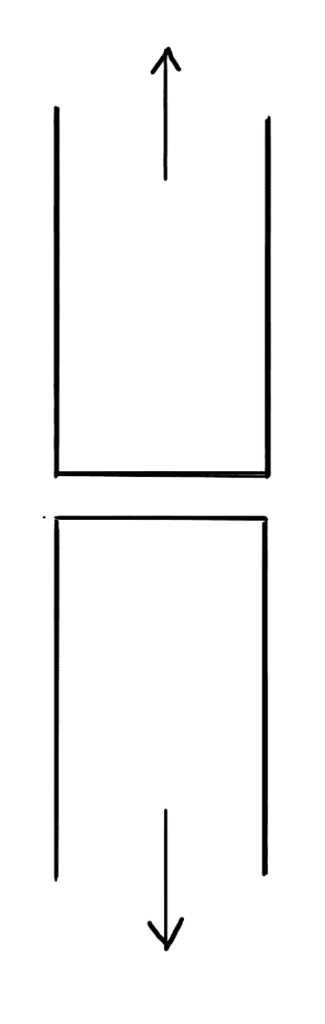

(a) Brittle Fracture of Single Crystals and polycrystals

A brittle fracture is characterized by separation normal to the tensile stress. Outwardly there is no evidence of deformation, although with X-ray diffraction analysis it is possible to detect a thin layer of deformed metal at the fracture surface.

Brittle fractures have been observed in Body-centered cubic (BCC) lattice and Hexagonal close-packed (HCP) metals, but not in Face-centered cubic (FCC) metals unless there are factors contributing to grain-boundary embrittlement.

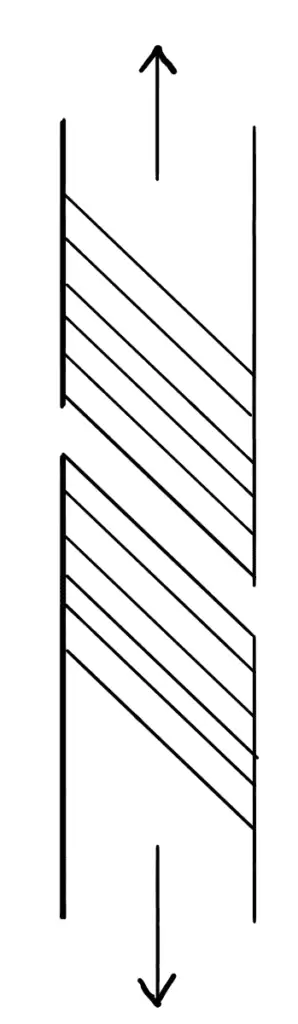

(b) Shearing Fracture in Ductile Single Crystals

Ductile fractures can take several forms. Single crystals of hep metals may slip on successive basal planes until finally, the crystal separates by shear.

(c) Completely Ductile Fracture in Polycrystals

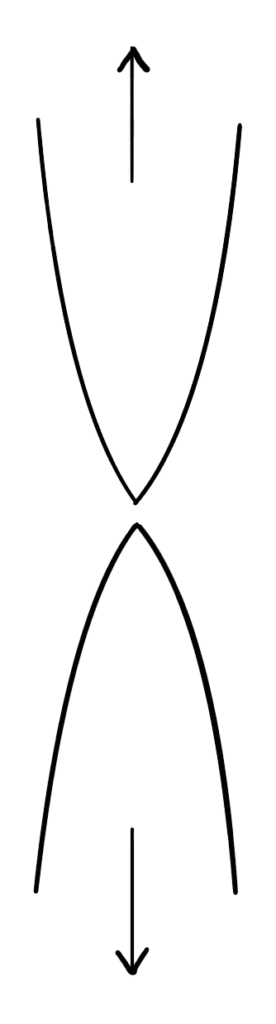

Polycrystalline specimens of very ductile metals, like gold or lead, may actually be drawn down to a point before they rupture.

(d) Moderate Ductile Fracture in Polycrystals

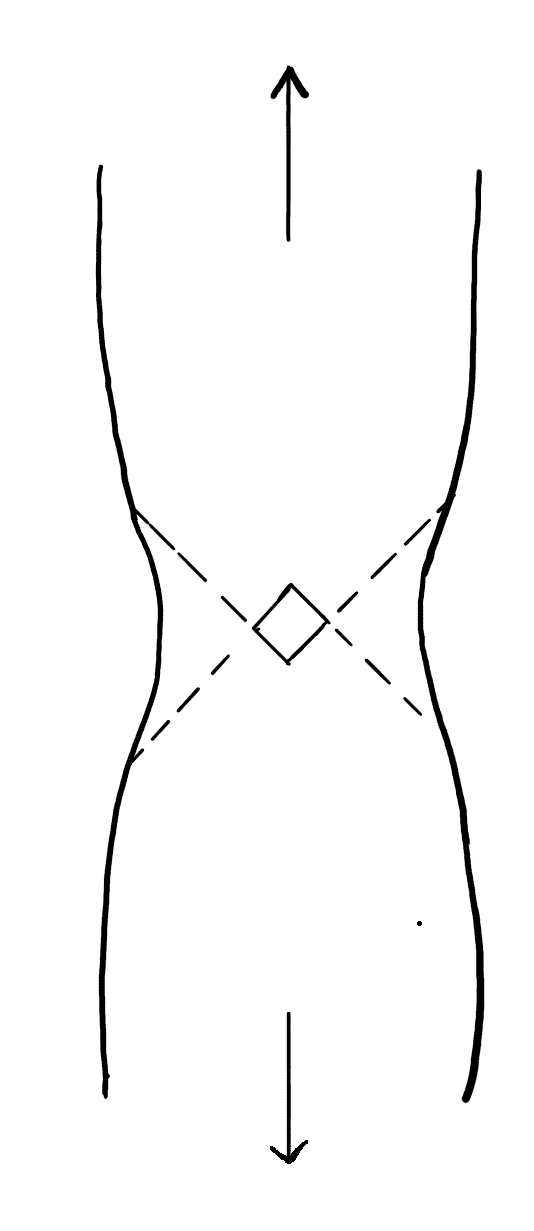

In the tensile fracture of moderately ductile metals, the plastic deformation eventually produces a necked region. Fracture begins at the center of the specimen and then extends by a shear separation along the dashed lines as shown in the above figure. This results in the familiar “cup-and-cone” fracture.

These are the different fractures observed when the specimen is subjected to the tensile load and the fracture produced is due to strain to fracture behavior.

There are other two characteristics for the fracture classification. Those are the Crystallographic Mode of Fracture and the appearance of the fracture.

Types of Fracture in metals according to the Crystallographic Mode of Fracture

- Shear Fracture

- Cleavage mode of Fracture

A shear fracture occurs as the result of extensive slip on the active slip plane. This type of fracture is promoted by shear stresses. The cleavage mode of fracture is controlled by tensile stresses acting normal to a crystallographic cleavage plane.

Types of Fracture in metals according to the Appearance of the Fracture

- Fibrous Fracture

- Granular Fracture

A fracture surface that is caused by shear appears at low magnification to be gray and fibrous, while a cleavage fracture appears bright or granular, owing to the reflection of light from the flat cleavage surfaces.

Fracture surfaces frequently consist of a mixture of fibrous and granular fracture, and it is customary to report the percentage of the surface area represented by one of these categories.

Based on the metallographic examination, fractures in polycrystalline samples are classified as either transgranular which means the crack propagates through the grains, or intergranular which means the crack propagates along the grain boundaries.

Conclusion

We have discussed the different types of fracture in metals according to the different characteristics. Those are Strain to Fracture, Crystallographic Mode of Fracture, Appearance of the Fracture.

Among the other material failures, Fracture failure, and fatigue failure and Creep failure are observed in the testing stage of prototypes. All these concepts are very important for every design engineer should have a deep understanding of. Let us know what do you think about this and let us know in the comment section below.

Leave a Reply