We have discussed Bernoulli’s Equation of motion (based on the Eulers equation). The Venturieter is a flowmeter that is used to measure the flow rates of fluids in a pipe in many industries. This Venturimeter works on the principle of Bernoulli’s Equation. Let us discuss more details such as the construction, working principle, different parts of venturimeter, and more…

Venturimeter

Venturimeter is a flowmeter that is used to measure the flow rates of fluids in a pipe in many applications such as water, chemical, pharmaceutical, and oil & gas industries.

The venturi meter is a differential head type flowmeter that can convert pressure energy into kinetic energy. In order to achieve this, the Venturi pipe cross-sectional area is reduced to create a pressure difference which is measured with a manometer to determine the rate of fluid flow.

Venturimeter Parts and Construction

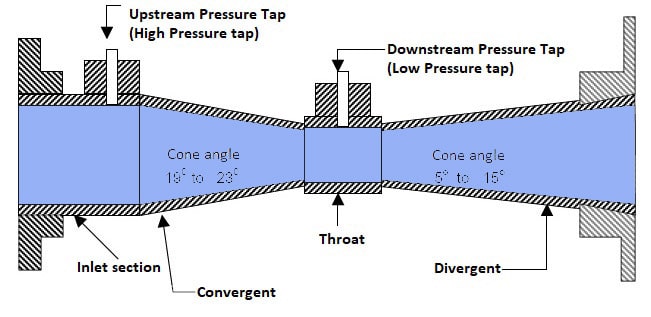

The venturimeter consists of 4 main parts, those are

- Inlet Section

- Conical convergent Cone

- Cylindrical throat

- Conical divergent outlet

- Upstream and downstream pressure tappings

Usually many Small-sized venturimeter can be made of brass, glass, or bronze and large venturimeters can be made of cast iron, steel, or stainless steel. Let us discuss these parts of the venturimeter.

1. Inlet Section

The Venturimeter inlet section is a straight cylindrical section with a length equal to 5 to 8 times the pipe diameter.

2. Convergent Cone

In Venturimeter, the convergent Cone section is where the diameter of the pipe gradually decreases. The conical angle is normally 21° ± 2°. While the liquid flows inside the venturimeter, at the Convergent Cone the velocity of fluid increases at the expense of a decrease in pressure.

3. Cylindrical Throat

In the Venturimeter, the Cylindrical throat consists of the minimum venturimeter diameter. In the Cylinder throat section, the velocity is maximum and the pressure is minimum. Generally, the cylinder throat diameter for any venturimeter will be 1/3 to 1/4th of the inlet section pipe diameter.

4. Conical Divergent Outlet

In the Venturimeter, at Conical Divergent Outlet, the tube diameter gradually increases. So, the pressure is built up again to the original inlet pressure. Generally, the conical angle will be 5° – 7° and 14° – 15° for the outlet cone as per the British standards.

5. Tappings

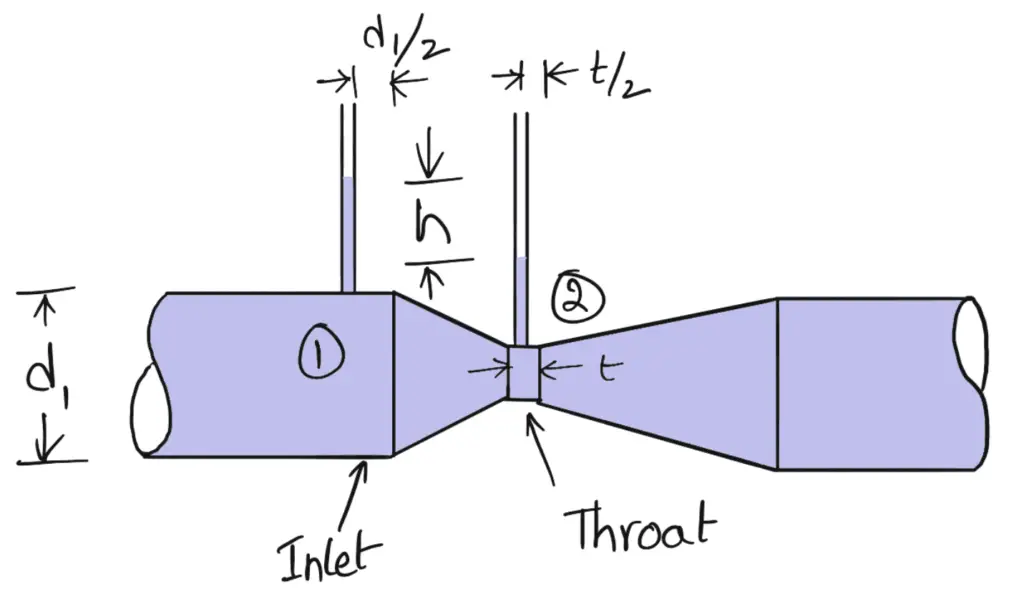

On venturimeter, there are two taps for the pressure measurement. The upstream pressure tapping is located at a distance of one-half of the pipe diameter (d1/2) upstream of the convergent entry, while the downstream pressure tapping is located in the throat (t/2) as shown in the below figure.

Venturimeter Working Principle

- In venturimeter, when a fluid flows through a venturimeter inlet section, it accelerates in the convergent cone section and then decelerates in the divergent section.

- The pressure difference between an upstream section and the throat is measured by a manometer.

- Using that differential pressure, applying Bernoulli’s Equation and Continuity Equitation the volumetric flow rate can be estimated.

- Usually, there are three types of venturimeters (Horizontal Venturimeter, Vertical Venturimeter, and Inclined Venturimeter)

- Horizontal Venturimeter has the highest kinetic energy and the lowest potential energy.

- Vertical Venturimeter has the maximum potential energy and the minimum kinetic energy.

- Inclined Venturimeter has both potential and kinetic energy in between the above two types mentioned.

Venturi Effect

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section (or choke) of a pipe.

Let us discuss the equations of venturimeter to find the discharge value.

Expression for rate of flow through Venturimeter

Let us consider a venturtmeter fitted horizontally through which a fluid (water) is flowing, as shown in the following figure.

Where

d1 = diameter at inlet or at section (1),

p1 = pressure at section (1)

v1 = velocity of fluid at section (1)

a1 = area at section (1) =ℼ/4) d12

d2, p2, v2 and a2, are corresponding values at section (2)

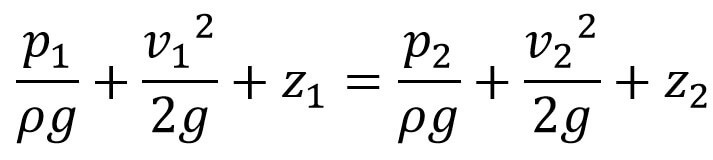

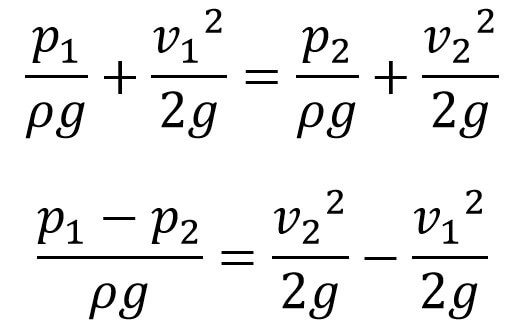

Applying Bernoulli’s equation at sections (1) and (2), we get

As we have assumed that the venturimeter is horizontal, hence z1 = z2

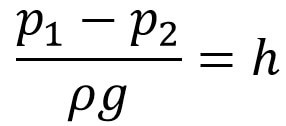

(p1 – p2)/ρg is the pressure difference heads at section 1 and 2 and it is equal to h.

Let us substituting this value in the above equation, we get

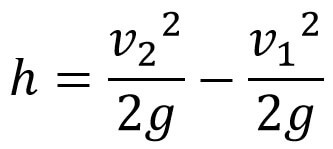

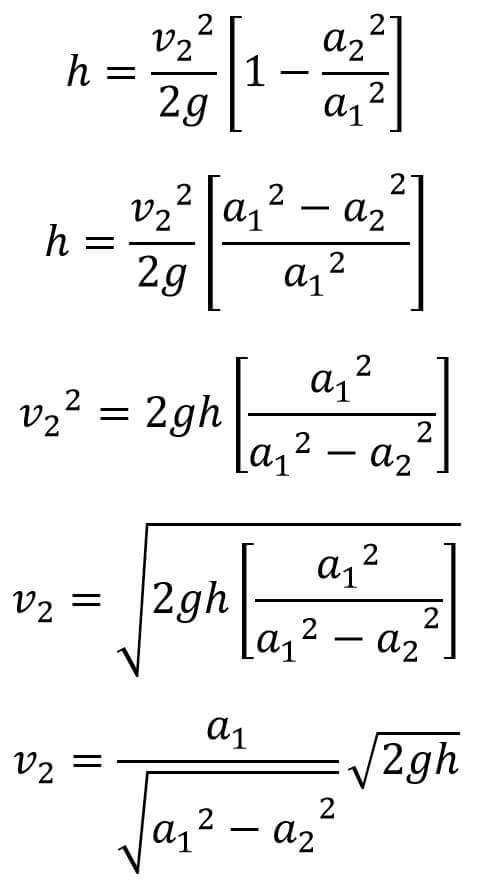

Now, apply the continuity equation at section 1 and 2

a1v1 = a2v2

v1 = (a2v2)/a1

Let us substitute the value v1 in the above equation (a)

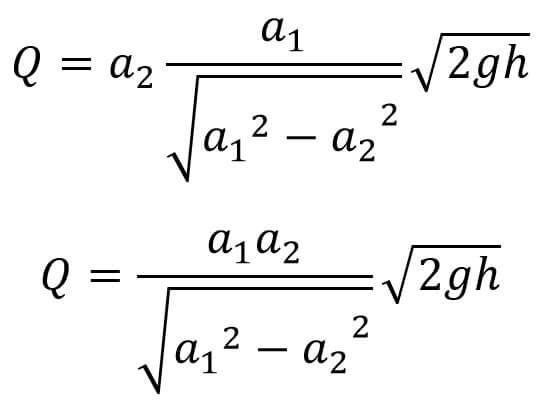

we know, Flow Discharge Q = a2v2

This equation (b) gives the flow discharge under ideal conditions. This is called theoretical discharge.

The actual discharge will be less than the theoretical discharge.

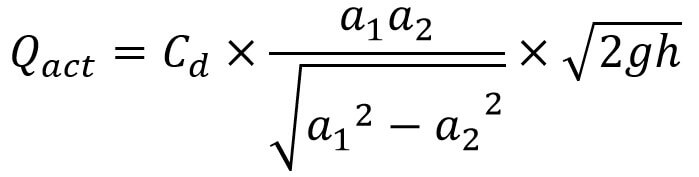

Coefficient of Ventuimeter

Coefficient of discharge for the venturimeter is the ratio of actual flow discharge to the theoretical discharge. Coefficient of Ventuimeter discharge can be represented by Cd. The Coefficient of venturimeter value is less than 1.

Cd = Qact/Q

Applications of Venturimeter

- Used in Engine Carburetors (Automobile Sector) to measure airflow

- Also used in Piping Industries to measure and control process flow.

- In the medical industry, blood flow in the arteries is measured by venturimeters.

- Measures the fluid flow inside pipelines (Oil & Gas Industries)

Advantages of Venturimeter

- Venturimeters can be installed in a horizontal, inclined, or vertical direction.

- No moving part in Venturimeter. Very low energy loss.

- Venturimeter provide accurate results.

- The accuracy of venturimeter is not dependent on temperature and pressure inside the pipe.

- Wide applicability for Water, suspended solids, gases, slurries, chemicals, dirty liquids, etc.

- High discharge coefficient and very low-pressure drop.

- Very less chance of being clogged.

- The pressure recovery of venturimeter is very high. The discharge pressure is almost near to inlet pressure.

Disadvantages of Venturimeter

- Expensive as compared to other types of flowmeters

- Limited range of flow measurement

- Venturimeter is not suitable for very small diameter pipes.

Leave a Reply