We have discussed the Air-standard cycles and the actual engines such as the spark-ignition and compression ignition engines. But the efficiency of these actual cycles is always less than the air-standard cycles. We have discussed the Comparison between the Air-standard cycles and the Actual cycles and listed the most influential factors such as the Time Loss Factor, Heat Loss Factor, Exhaust Blowdown Factor. In this article, we are going to discuss Time loss Factor.

Time Loss Factor

In Air-standard cycles, the combustion (Heat addition) assumed to be instantaneous, But in actual cycles, it will take a definite period of time. Approximately the crankshaft will turn about 30° to 40° of rotation during the overall combustion process (Spark creation to till complete combustion). This is the time loss due to progressive combustion.

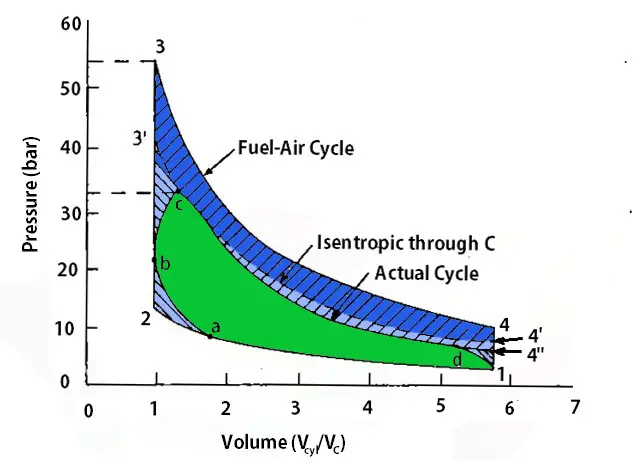

Following is the P-V diagram for the Internal combustion engine. Represented with the fuel-air cycle and the Actual cycle.

Due to the time taken for the complete combustion, the peak pressure generated by the combustion at the minimum cylinder volume (At 2) will not occur, Which means at the piston at the TDC. It will occur sometime after the TDC. The pressure will rise from b to c as shown on the graph.

Path 2 → 3 represents if the combustion is instantaneous at constant volume. Which mean instantaneous at where the piston is at TDC.

But the path

The path 2 → 3 represents the expansion stroke in the air-standard cycle. Whereas the path

The area which is hatched and painted them in blue represents the amount of work would have been done. This loss of useful work results in reduced in the efficiency of the cycle. This is called the time loss due to progressive combustion.

Factors cause the Time loss in actual cycles

- The flame velocity which in turn depend upon the type of fuel and the fuel-air ratio.

- The shape and size of the combustion chamber.

- The distance from the point of ignition to the opposite side of the combustion space

What we can do to reduce the time loss factor or maintain the peak pressure in the cylinder?

We can simply vary the spark time in advance in actual timing.

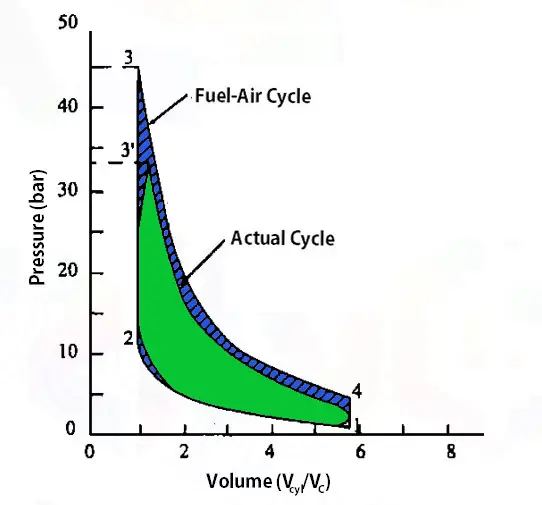

Following are the different variations of spark time by the crank angle.

| Cycle | Ignition Advance | Max. cycle pressure (bar) | Mean effective pressure (bar) | Efficiency (%) | Actual cycle Ƞ / Fuel cycle Ƞ |

| Fuel Air cycle | 0° | 44 | 10.20 | 32.2 | 1.00 |

| Actual cycle | 0° | 23 | 7.50 | 24.1 | 0.75 |

| Actual cycle | 17° | 34 | 8.35 | 26.3 | 0.81 |

| Actual cycle | 35° | 41 | 7.60 | 23.9 | 0.74 |

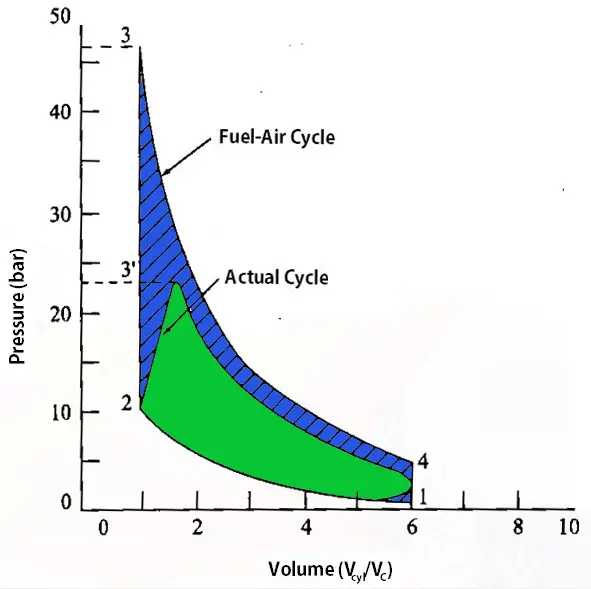

We have the following graph representation of the P-V diagram for actual and the fuel-air cycle for the Spark advance by 0°

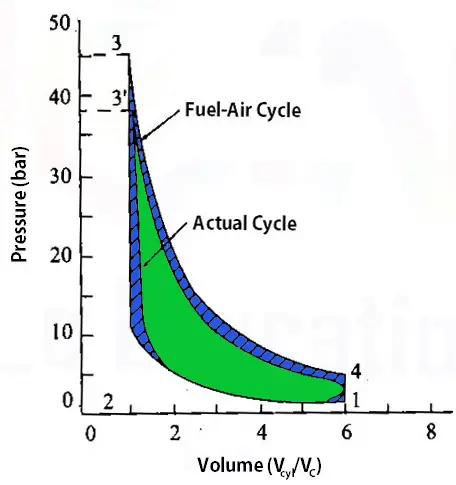

P-V diagram for actual and the fuel-air cycle for the Spark advance by 35°. The combustion will be completed by the time of the

P-V diagram for actual and the fuel-air cycle for the Spark advance by 35°

Conclusion

This is basic info about the time loss factor in the actual engines. If you have any thoughts about this topic, let us know in the comment section below.

Leave a Reply