Solex Carburetor is one of the famous Carburetor for the ease of starting the engine and the best performance of the engine. Let’s discuss the construction and the working principle of the Solex Carburetor.

Solex Carburetor

Solex Carburetor is a downdraught Carburetor. This is

This Carburetor has different fuel discharge circuits so that it can deliver different mixtures for the different operating conditions such as the Engine Starting, Engine Idling, Low-speed Operation, Normal Operating, Acceleration.

Construction of Solex Carburetor

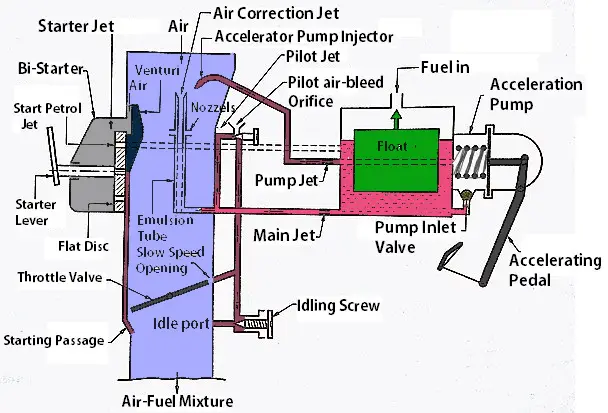

A float with a tapered valve at the top face of the float is arranged in the float chamber to take care of the fuel level in it as shown in the below schematic representation.

Let’s discuss the different circuits with the different operating conditions

Engine Normal Running

- The Main metering Jet will discharge the fuel into the venturi throat tube.

- The fuel from the main metering jet will go into the air-bleed emulsion system, this has the lateral holes as shown in the schematic diagram.

- Air correction jet calibrates the air entering through it and ensures the air-fuel balance.

- The metered emulsion of fuel and air is supplied through the spraying orifice or nozzles. These nozzles are drilled horizontally on the vertical pipe in the choke tube as shown in the schematic diagram.

- There is a throttle valve provided at the end of the tube to control the air-fuel mixture quantity supply into the engine. This valve also knows as the conventional butterfly valve.

With this circuit, the engine can run at the normal running with this Solex Carburetor. But for the other operating conditions of the engine, we will use different fuel circuits for different operating conditions.

Cold starting and warming

The main advantage with the Solex Carburetor is that it has the Bi-Starter also known as the progressive starter. Initially, the engine needs a richer mixture and the after starting of the engine, the mixture supposed to be lean. So this progressive starter will do the job for the engine.

- This starter is in the form of a flat disc with the holes of different sizes.

- The starter petrol jet and the starter jet (Air) are connected together by the holes present in the starter disc and open into the passage arranged to below the throttle valve.

- There is a starter lever that used to adjust the hole sizes so that the amount of the fuel and the air will be passed to the engine cylinder in the suction stroke.

- When we starting the engine we will close the throttle and provide the air-fuel mixture from the starting passage which is having a richer mixture from this Bi-Starter setup.

Once the engine started, we have to warm it up by accelerating a couple of times and then release the throttle valve and pass the lean/normal mixture thru the venturi throat.

Idling and Slow Running of the Engine(Cruising)

Idling of the engine is at where the engine will not deliver any work it only delivers enough power for its auxiliaries. During this idling or slow running of the engine needs to have a rich mixture and because of the cylinder pressure is less and then there is a chance of re sucking of the exhaust gases and cause the poor combustion to make the engine stumble. So this rich mixture helps in making it happen smooth.

- During the Idling, the throttle valve is closed completely.

- The suction created by the suction stroke is acted on the pilot jet directly.

- The fuel will be inducted from the pilot jet and mixed with the less amount of air sucked from the pilot air-bleed orifice from the outside atmosphere.

- This rich mixture will be directly sent to the cylinder by a tube directly opened right below the throttle valve as shown in the schematic diagram.

- There is an idle speed adjustment screw is arranged so that we can set the idle speed of the engine by controlling the amount of mixture injected.

- For the smooth running adjustment, we will have an additional by-pass adjustment. (Not shown in the schematic representation) Which will make the less rich mixture and the throttle will also open a little bit. so that engine can run smoothly with the full movement of the air-fuel mixture.

Acceleration of Engine

For the Engine acceleration, and additional acceleration pump injector equipment is arranged right side of the floating chamber as you can see from the schematic diagram. This acceleration pump will supply the additional fuel for the engine with the help of the Acceleration pump injector directly on top of the venture. The operating of the Carburetor is the

This is the construction and the working principle of the Solex Carburetor.

Conclusion

We have discussed the different operating conditions of the engine run by the Solex Carburetors with different functions such as the Normal operating, Idling, Slow running, and acceleration. Let us know your thoughts in the comment section below.

Leave a Reply