We have already discussed What is Carburetion in the previous article, in this article we are going to discuss the working principle of a simple Carburetor with a schematic diagram.

Simple Carburetor

The process of preparation of a combustible air-fuel mixture by mixing the proper amount of fuel with the air before it goes into the cylinder is called Carburetion.

We have to use a special device for this action called Carburetor.

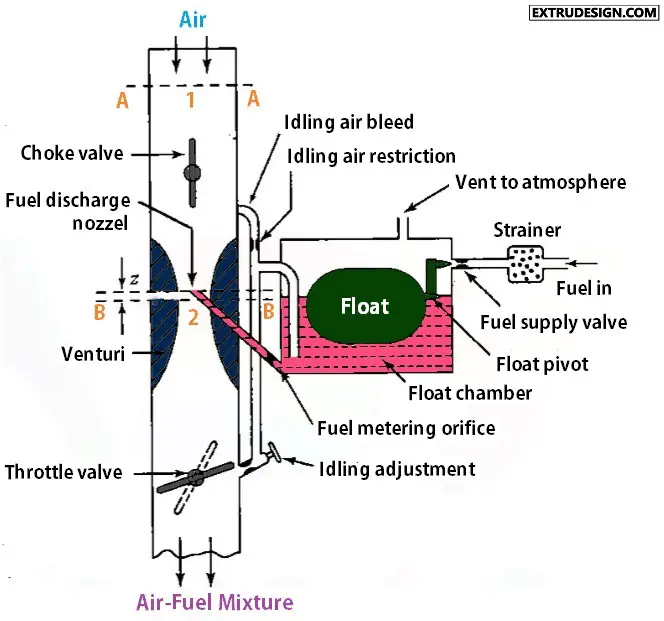

Usually, Carburetors are highly complex. The following figure shows the details of a simple Carburetor.

The simple Carburetor mainly consist of the following components

- Float Chamber

- Fuel discharge nozzle

- Metering orifice

- Venture throttle valve

- choke Valve

Construction

The float attached with a needle is located inside the float chamber and maintains a constant level of petrol inside the float chamber. There is a vent provided for the float chamber to atmosphere/upstream side of venturi to maintain pressure. Venturi tube is decreasing cross-section with a minimum area at the throat. This venturi tube is also known as the choke tube. This tube designed in such a way that it has very least resistance to the air flow. The choke valve is located in the air flow path and the fuel throttle valve is located after the venturi tube in the air flow path. Metering orifice and fuel discharge nozzle are connected to the float chamber to deliver the fuel at the venturi throat to prepare the mixture.

Working Principle of Simple Carburetor

- As the fuel level in the fuel chamber goes down, the float in the float chamber will also go down. The

needle attached to the float will be moved away from the fuel supply valve. - so that the fuel will come in thru the strainer which will be used to separate the solid material formations from the fuel.

- Once the fuel level reaches the designed level then the float closes the fuel supply valve with the help of the needle.

- During the engine suction stroke, the air will be drawn thru the venturi tube and the velocity will be gradually increased and rein the venturi tube.

- The air velocity will be maximum at the venturi’s throat. And the pressure reaches a minimum value.

- The fuel discharge valve will inject the fuel at his position.

- Due to the differential pressure in the float chamber and the venturi throat, the fuel will be automatically discharged into the air stream.

- The air-fuel ratio will depend on the fuel discharge nozzle size.

- To control the fuel amount on to the throat the fuel level in

float chamber is maintained slightly below than the fuel discharge nozzle tip height as shown in the above schematic diagram. - The power output of the engine can be varied by discharging the amount of fuel mixture quantity into the cylinder governed by the throttle valve situated after the venturi tube.

Drawbacks of simple Carburetor

The main functional drawback of the simple Carburetor is that it can only provide one air-fuel ratio at the one throttle position. The other throttle positions give either a lean mixture or richer mixtures.

Conclusion

We have discussed the simple Carburetor main components, construction, working principle and the disadvantages. Let us know your thoughts in the comment section below.

Leave a Reply