In the previous article, we have discussed the important qualities of the Spark Ignition engine fuels and the Compression-Ignition Engine Fuels. In this article, we are going to discuss the Rating of fuels for both engine fuels.

Rating of Fuels

There are to important parameters that rate the engine fuels. Those are Octane number for the petrol, Cetane Number for Diesel. Usually, the rating of the fuels will be done by their antiknock characteristic.

Rating of Spark-Ignition Engine Fuels

- Anti-knocking is one of the major characteristics for the Spark-Ignition Engine Fuel.

- The resistance to the knocking is completely depended on the chemical composition of the fuel.

- Apart from this, there are other parameters which result in knocking in the spark-ignition engine, those are the air-fuel ratio, ignition timing, engine speed, dilution, the shape of the combustion chamber, compression ratio, ambient conditions.

- So before we rate the anti-knock characteristics of the fuel we have to fix those parameters to the standard values.

Normally fuels are rated for their antiknock characteristics. To determine the antiknock characteristics of any fuel it can be done by comparing its antiknock property with a mixture of two reference fuels. one which is having the high octane number, and another one which will have less octane number.

Iso-Octane (C8H18) is rich in the octane. It is around 100 as the octane number, on the other hand, the normal heptane (C7H16) has 0 as the octane number. These two are used as the reference fuels to determine the antiknock characteristics.

The Octane number of a

fuel is defined as the percentage by the volume of the Iso-Octane in the mixture of Iso-octane and the normal heptane, Which will exactly match the knocking intensity of the test fuel in a standard engine under the standard operating conditions.

The addition of certain compounds such as the tetraethyl lead to the Iso-Octane will result in the fuel with a greater antiknock property.

At the high range octane number, even a small change in the octane number brings grater antiknock property. For example, the octane number increases from 92 to 93 will result in the greater antiknock property than the octane n

Due to this progressive character of the octane number effectiveness on the antiknock property, there is a new scale derived to expresses the octane number relative to the performance of the engine.

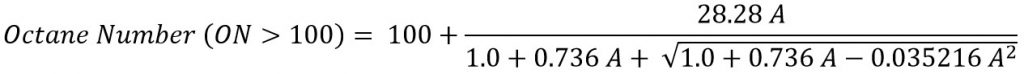

Octane number above 100 can be computed by using the following formula

Where ‘A’ is the amount of Tetra-ethyl lead in ml/gal of fuel

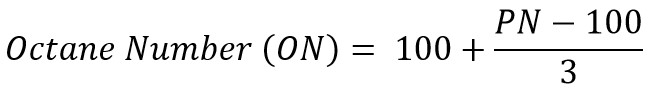

In other words, the Octane number can be computed with Performance Number (PN) by using the following formula.

Laboratory Method:

- A knock meter is used to measure the knocking in the engines.

- First of all, we have to measure the standard knock in for the engine at the standard operating conditions.

- The spark-Ignition engine will be run at specified conditions with the standard compression ratio and a definite composition of reference fuels. So that we can measure the standard knock in the engines.

- Now put the fuel which needs to be tested into the engine, and the air-fuel ratio needs to be adjusted to get the maximum knock in the engine (the worst case scenario).

- Now, The compression ratio of the engine needs to be adjusted to bring down the knock meter reading to the match the standard knock reading.

- Now the compression ratio is fixed and the composition of the reference fuel is known.

- Which means we have matched the knocking produced by the reference fuels in the engine with the knocking produced by test fuel.

- Percentage by volume of iso-octane in the particular composition of reference fuel gives the octane number.

Rating of Compression-Ignition Engine Fuels

- In the Compression Ignition engines, the antiknock characteristics will depend on the chemical composition an also on the design and operating conditions of the engine.

- The knock rating is done by comparing the fuel under prescribed conditions of operations in a special engine with the reference fuels.

The reference fuels are normal Cetane (C16H34) having the cetane number as 100 and the second one is alpha methylnaphthalene (C11H10) having the cetane number as 0.

The Cetane Number is defined as the percentage by the volume of the normal Cetane in the mixture of Normal Cetane and the alpha methylnaphthalene, Which will exactly match the ignition characteristic of the test fuel in a standard engine under the standard operating conditions.

Since the Ignition delay is the main character that can control the auto-ignition in the compression ignition engines. So this character can be helpful to conclude the knock character in the CI engines. Which means the Ignition delay is directly related to the knock character.

Adding of the Amyl nitrate, ethyl nitrate or ether can improve the antiknock characteristic.

Laboratory Method

This test must be carried out under certain operating conditions shown in the below table with the single cylinder such as the CFR (Cooperative Fuel Research) diesel engine or Ricardo single cylinder variable compression engine.

| Engine speed | 900 RPM |

| Jacket water temperature | 100° C |

| Inlet air temperature. | 65.5° C |

| Fuel Injection advance | Constant at 13° before TDC |

| Ignition delay | 13° |

- First, the test fuel is used in the engine at the specified operating conditions.

- The Fuel injection delivery pump also need to be adjusted to give a correct fuel-air ratio.

- The fuel injection timing needs to be set to 13° before the Top Dead Centre (TDC)

- Now we have to find the position for the ignition at the TDC to get the ignition delay by 13° by varying the compression ratio.

- Now the Cetane number can be found by noting down the compression ratio at which the ignition delay is 13°.

- As we said earlier the ignition delay is directly relative to the knock character in the compression engines.

The cetane number of the unknown fuel can be estimated by noting down the compression ratio of 13° and then referring to a prepared chart shown the relationship between cetane number and combustion ratio.

However, for accuracy two reference fuel compositions differing by not more than 5 cetane numbers are selected to bracket the unknown sample. The compression ratio is varied for each reference blend to reach the standard ignition delay (13°) and by interpolation of the compression ratios, the cetane rating of the unknown fuel is determined.

Conclusion

We have discussed the rating of fuels for both the Spark-Ignition engine fuels and for the Compression-Ignition engine fuels with the traditional method and the laboratory example. If you have any thoughts on this topic, Please let us know in the comment section below.

Leave a Reply