In Spark Ignition Engine the self-ignition temperature of the fuel (Petrol) is very high and the compression ratio is lower, so we must have to have an Ignition system for the SI engines. There are different Ignition Systems available. In this article, we are going to discuss the functional requirements of the Ignition system and the different types of ignition systems in an elaborative manner.

Significance of Ignition System

The Ignition system will supply the sufficient voltage for the Spark plug electrodes to effect the spark discharge. And also it will supply the required amount of energy for the spark to ignite the combustible mixture adjacent to the plug electrodes under all operating conditions.

The spark timing will be also controlled by the Ignition system. But it will vary with the engine speed, inlet manifold pressure and mixture composition.

Requirements of Ignition Systems

The basic functional requirements of the Ignition_system for a reliable working engine are mentioned below.

- It should provide a good spark between the electrodes at the correct timing.

- Able to work efficiently over the entire range of engine speed.

- Should be compact in design and easy for maintenance

- It should be cheap and convenient to handle, lite, effective and reliable in service.

- It should not affect the radio and televisions receivers due to the interference from the high voltage source.

These are the basic functional requirements of the Ignition system.

Types of Ignition System

- Battery Ignition System

- Magneto Ignition System

1. Battery Ignition System

In the current trend, most of the moderns SI engines run with the Battery Ignition system. In this system, the energy for producing the spark is obtained from a 6 volt or a 12-volt battery.

The Ignition system is said as the heart of the engine, and it is a part of the engine, not an independent one. It must be matched with the engine. so the construction of the battery Ignition system will be varied. It depends on the type of ignition energy storage and ignitions performance which is required by the particular engine.

Following are the list of essential components in the Ignition system

- Battery

- Ignition switch

- Ballast resistor

- Ignition coil

- Contact breaker

- Capacitor

- Distributor

- Spark plug

Construction of Battery Ignition System

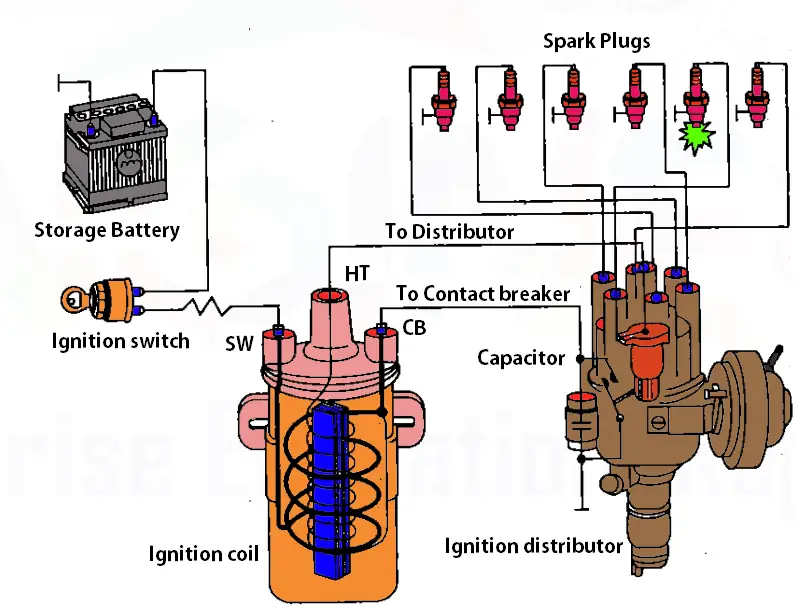

A storage battery is used to supply and store the electrical energy for the ignition, this will be charged by the dynamo which is driven by the engine.

As you can see from the schematic diagram an Ignition switch is connected in the primary winding of the ignition coil to the ballast resistor. This is used to switch off/on the ignition.

A ballast resistor is connected in series to the Ignition switch to regulate the primary current.

An ignition coil is a source for the ignition energy in the Ignition system. This coil stores the energy and delivers at the right time in the form of ignition pulse through the high tension ignition cables to the respective spark plug.

A contact breaker is a mechanical device for making and breaking the primary circuit of the ignition coil. It will be operated by a cam operated pivoted arm.

There is an Ignition Capacitor which is the same as every electrical capacitor. Two metal plates separated by an insulating material are placed face to face.

A Distributor is connected in the circuit to distribute the ignition pulse to the individual spark plugs in the correct sequence and at the correct instants.

The spark plug is the one which catches the ignitions pulse and creates the spark by two electrodes placed with sufficient gap between them.

Operation of Battery Ignition system

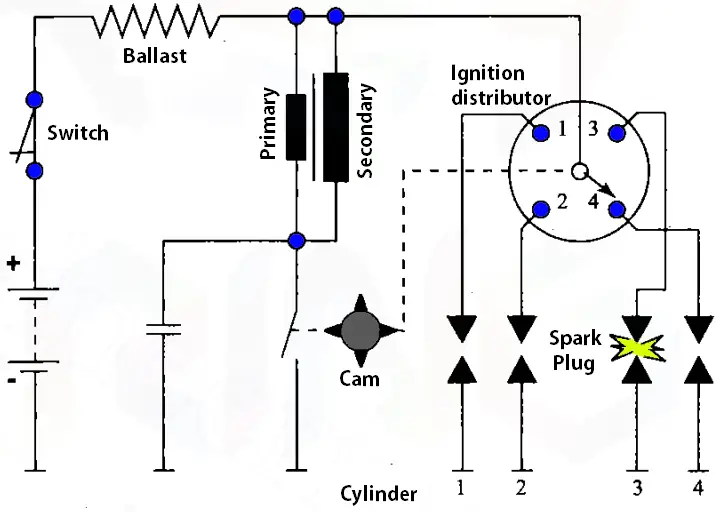

The Ignition coil is the source for the ignition energy in the battery ignition system. It will deliver the ignition energy in the form of a surge of the high voltage current to the spark plug. See the following schematic representation the battery ignition system circuit for the four-stroke engine.

- There are two winding of the coil. one is called the primary and the other one is secondary.

- The primary winding is connected to the position terminal of the storage battery with the ignition switch and the ballast in series.

- On the other end of the primary winding is connected to the contact breaker and to the ground.

- A capacitor is connected in parallel to the contact breaker as shown in the above figure. This is the primary circuit.

- The secondary winding will be connected to the ground through the contact breaker.

- The other end of the secondary coil will be connected through the distributor through the high tension ignition cables to the centre electrode of the spark plug.

- Once the switch closed, then the primary circuit will complete. Thus the primary current will flow through the primary coil and created the magnetic field on the core of the Ignition coil.

- a cam driven by the engine will be arranged to open the breaker points whenever an ignition discharge is required.

- The primary current will follow through the condenser and the condenser will be charged.

- Once the condenser is charged then the primary current flow will be stopped, due to that the magnetic field also collapses.

- The collapse of the magnetic field will cause a voltage in the primary winding which charges the condenser to a voltage higher than the storage battery voltage.

- Then the condenser will start discharge the voltage into the battery by reversing the primary current direction and the magnetic field.

- This rapid collapse of the magnetic field and reversing in the direction will result in very high voltage in the secondary winding of the ignition coil.

- This high amount of voltage will be lead to the proper spark plug by the distributor.

- The timing of the spark will be controlled by the crank angle at which the breaker points open.

This is how the battery ignition will work.

Limitations of a Battery Ignition system

- The primary voltage will decrease as the engine speed increases due to the current switching capability of the breaker system.

- The time available for the build-up of current in the primary current will be decreased if the engine speed increases due to the dwell period become shorter.

- short maintenance interval due to involving o the mechanical means such as the contact breaker and the cam operations. these parts may wear.

2. Magneto Ignition System

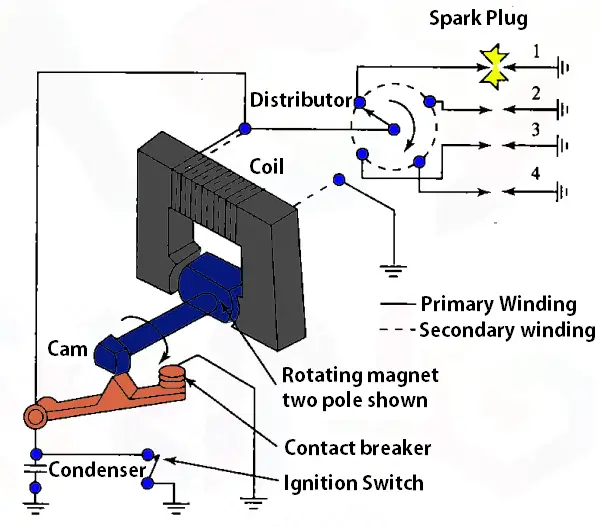

Magneto ignitions system is a special type of ignition system. It is having its own electrical generator as the energy resource to provide the necessary amount of energy for the system.

Following is the schematic representation of the Magneto Ignition System

As we have already discussed the battery Ignition_system and the components present in it, but In the Magneto Ignition_system all the components will be replaced except the spark plug.

Since this Magneto Ignition System has the magnet rotated by the engine is capable of producing enough high voltage for the spark plug instead of the battery energy source.

As you can see the above schematic representation of the Magneto Ignition system. A magneto has arranged the winding to generate the high voltage to deliver to the spark plug.

The rest of the working principle is the same as the Battery coil ignition system.

There are three different possible magneto Ignitions systems available. First one is which rotating armature type, the second one is rotating magnet type, the third one is that both the armature and the magnet will be constant and the voltage is generated by reversing the flux field with the help of the soft iron polar projections called inductors. so this third one is called the Polar Inductor type.

This is all about the Ignition system and the different types available in it.

Conclusion

We have discussed the Ignition systems with the basic functional requirements and the different types of ignition systems (Battery Ignition_system, Magneto Ignition_system) with their schematic representations and the operations. If you have any further thoughts on this topic, let us know in the comment section below.

Leave a Reply