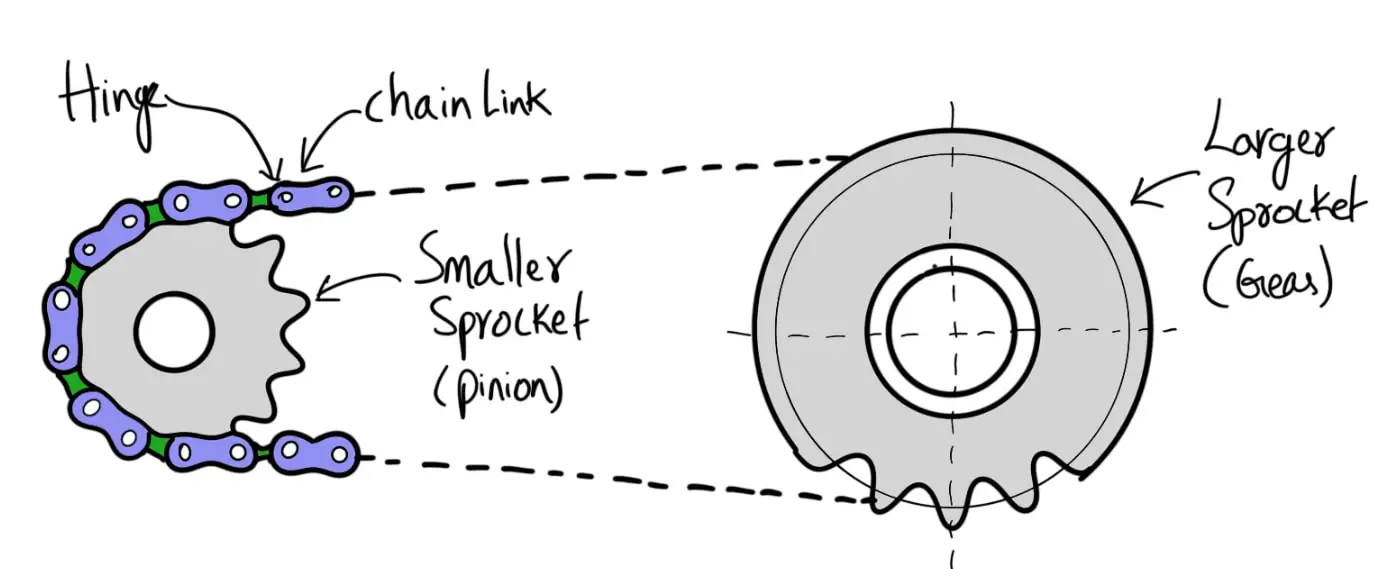

We have discussed belt drives and rope drives that slipping may occur. To avoid slipping, steel chains are used. The chains are made up of a number of rigid links which are hinged together by pin joints to provide the necessary flexibility for wrapping around the driving and driven wheels. These wheels have projecting teeth of special profile and fit into the corresponding recesses in the links of the chain. The toothed wheels are known as sprocket wheels or simply sprockets (These wheels resemble spur gears). The sprockets and the chain are thus constrained to move together without slipping, ensuring a perfect velocity ratio. We have already discussed Chain Drive Terminology, Classification, and Advantages in the previous article. We also calculated how we can calculate the power transmitted by the chains. Let us now discuss the Factor of Safety for the Chain Drives.

Chain Drive: Chains and Sprockets

The chains are mostly used to transmit motion and power from one shaft to another when the center distance between their shafts is short such as in bicycles, motorcycles, agricultural machinery, conveyors, rolling mills, road rollers, etc. The chains may also be used for long center distances of up to 8 meters. The chains are used for velocities up to 25m/s and power up to 110 kW. In some cases, higher power transmission is also possible.

Following is a schematic Representation of a Chain Drive that comprises Sprockets and a chain.

We have also discussed how we can calculate the Length of Chain and Centre Distance, Power Transmitted by chains, and a complete design procedure of Chain drives. Check it out here.

Now let us discuss the Factor of Safety for Chain Drives

Factor of Safety for Chain Drives

The factor of safety for chain drives is defined as the ratio of the breaking strength (WB ) of the chain to the total load on the driving side of the chain (W). Mathematically,

The breaking strength of the chain may be obtained by the following empirical relations, i.e.

WB = 106 p2 (in newtons) for roller chains

WB = 106 p (in newtons) per mm width of chain for silent chains.

where p is the pitch in mm.

The total load (or total tension) on the driving side of the chain is the sum of the tangential driving force (FT), centrifugal tension in the chain (FC), and the tension in the chain due to sagging (FS).

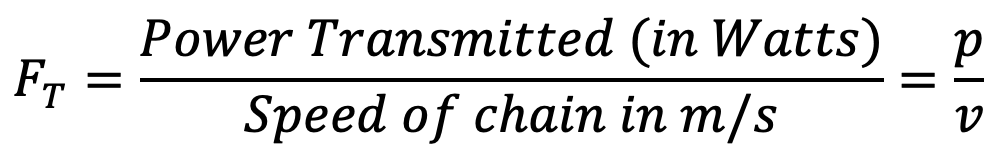

We know that the tangential driving force acting on the chain,

Centrifugal tension in the chain,

FC = m.v2 (in newtons)

and tension in the chain due to sagging,

FS = k.mg.x (in newtons)

where

m = Mass of the chain in kg per meter length

x = Centre distance in meters

k = Constant which takes into account the arrangement of the chain drive

= 2 to 6, when the center line of the chain is inclined to the horizontal at an angle less than 40o

= 1 to 1.5, when the center line of the chain is inclined to the horizontal at an angle greater than 40o.

This value of the factor of safety should be greater than the value given in the following table.

| Type of chain | Pitch of chain (mm) | Speed of the sprocket pinion in r.p.m. | ||||||||

| 50 | 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 | 2000 | ||

| Bush roller chain | 12 – 15 20 – 25 30 – 35 | 7 7 7 | 7.88.2 8.55 | 8.55 9.35 10.2 | 9.35 10.3 13.2 | 10.2 11.7 14.8 | 11 12.9 16.3 | 11.7 14 19.5 | 13.2 16.3 – | 14.8 – – |

| Silent chain | 12.7 – 15.87 19.05 – 25.4 | 20 20 | 22.2 23.4 | 24.4 26.7 | 28.7 30.0 | 29.0 33.4 | 31.0 — 33.4 36.8 — 40.0 | 37.8 46.5 | 42.0 53.5 | |

Let us also discuss the Permissible Speed of Smaller Sprocket and the Maximum Speed for Chains.

Permissible Speed of Smaller Sprocket

The following table shows the permissible speed of the smaller sprocket or pinion (in r.p.m.) for the bush roller and silent chain corresponding to different pitches.

| Type of Chain | Number of teeth on sprocket pinion | Pitch of chain (p) in mm | ||||

| 12 | 15 | 20 | 25 | 30 | ||

| Bush roller chain | 1519 2327 30 | 23002400 25002550 2600 | 19002000 21002150 2200 | 13501450 15001550 1550 | 11501200 12501300 1300 | 10001050 11001100 1100 |

| Silent chain | 17 – 35 | 3300 | 2650 | 2200 | 1650 | 1300 |

Note: The chain velocity for the roller chains may be as high as 20 m/s, if the chains are properly lubricated and enclosed, whereas the silent chain may be operated up to 40 m / s.

Maximum Speed for Chains

The maximum allowable speed for the roller and silent chains, depending upon the number of teeth on the smaller sprocket or pinion and the chain pitch is shown in the following table.

| Type of chain | Number of teeth on the smaller sprocket (T1) | Chain pitch ( p) in mm | ||||

| 12 | 15 | 20 | 25 | 30 | ||

| Roller chain | 15 19 23 27 30 | 2300 2400 2500 2550 2600 | 1900 2000 2100 2150 2200 | 1350 1450 1500 1550 1550 | 1150 1200 1250 1300 1300 | 1100 1050 1100 1100 1100 |

| Silent chain | 17–35 | 3300 | 2650 | 2200 | 1650 | 1300 |

Note: The r.p.m. of the sprocket reduces as the chain pitch increases for a given number of teeth.

This is all about the Factor of Safety for Chain Drives. Let us know your thoughts on this article in the comment section below.

Leave a Reply