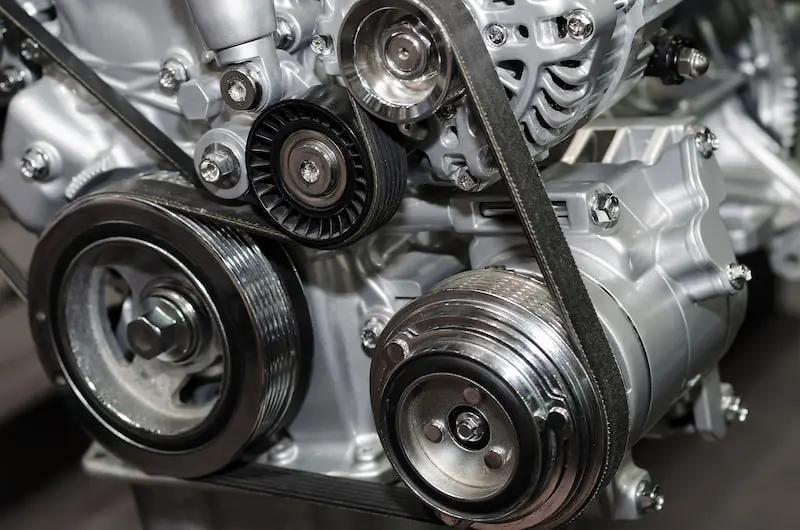

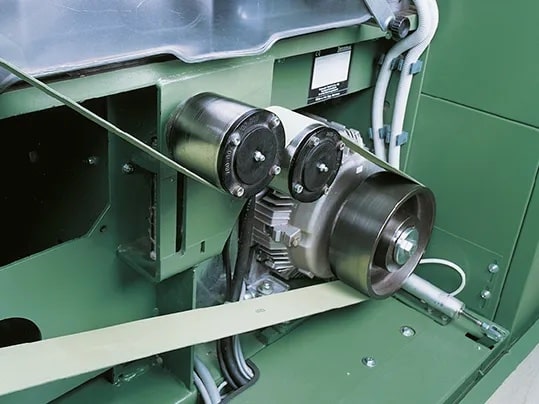

The belts or ropes are used to transmit power from one shaft to another by means of pulleys that rotate at the same speed or at different speeds. The material used for belts and ropes must be strong, flexible, and durable. It must have a high coefficient of friction. Let us see what are the different materials used for belts in belt drives in this article.

According to the material used, the belts in belt drives are classified as follows

- Leather Belts

- Cotton or fabric belts

- Rubber belt

- Balata belts

Leather Belts

Leather belts are one of the most important materials used for Belts (Flat Belts). The best leather belts are made from 1.2 meters to 1.5 meters long strips cut from either side of the backbone of the top-grade steer hides. The hair side of the leather is smoother and harder than the flesh side, but the flesh side is stronger. The fibers on the hair side are perpendicular to the surface, while those on the flesh side are interwoven and parallel to the surface. Therefore for these reasons, the hair side of a belt should be in contact with the pulley surface.

This gives a more intimate contact between the belt and the pulley and places the greatest tensile strength of the belt section on the outside, where the tension is maximum as the belt passes over the pulley.

The leather may be either oak-tanned or mineral salt-tanned e.g. chrome-tanned. In order to increase the thickness of the belt, the strips are cemented together. The belts are specified according to the number of layers e.g. single, double, or triple ply, and according to the thickness of hides used e.g. light, medium, or heavy.

The leather belts must be periodically cleaned and dressed or treated with a compound or dressing containing neats foot or other suitable oils so that the belt will remain soft and flexible.

Cotton or Fabric Belts

Most of the fabric belts are made by folding convass or cotton duck into three or more layers (depending upon the thickness desired) and stitching them together. These belts are woven also into a strip of the desired width and thickness.

They are impregnated with some filler like linseed oil in order to make the belt waterproof and to prevent injury to the fibres. The cotton belts are cheaper and suitable in warm climates, damp atmospheres, and in exposed positions. Since cotton belts require little attention, therefore these belts are mostly used in farm machinery, belt conveyor, etc.

Rubber Belt

The rubber belts are made of layers of fabric impregnated with rubber composition and have a thin layer of rubber on the faces.

These belts are very flexible but are quickly destroyed if allowed to come into contact with heat, oil, or grease.

One of the principal advantages of these belts is that they may be easily made endless. These belts are found suitable for sawmills, and paper mills where they are exposed to moisture.

Balata Belts

These belts are similar to rubber belts except that balata gum is used in place of rubber. These belts are acid-proof and waterproof and it is not affected by animal oils or alkalies.

The balata belts should not be at temperatures above 40°C because at this temperature the balata begins to soften and becomes sticky. The strength of balata belts is 25 percent higher than rubber belts.

These are the 4 different types of materials used for belts in belt drives. Let us know what you think about this article in the comment section below.

Leave a Reply