Pipes are used to transporting the fluids such as water, steam, gases, oil and chemicals. So these pipes may undergo internal pressure for some applications and for some not. Many of us wondered about the pipes that we see to transport the fluids that are going to withstand the pressure exerted by the fluid or not. Yes, those pipes are designed in such a way that they can transport the fluid without any failure. In this article, we are going to learn about how to design a pipe to withstand fluid pressure.

In the Previous Article, we have discussed the formulas for the stresses in Thick cylinders and Thin cylinders. Based on the concepts of a thin cylinder we will design a pipe to transport fluid under pressure.

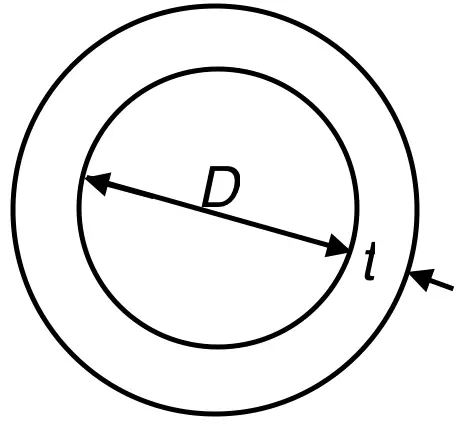

To design a pipe we need two main parameters.

- Inside Diamter of the Pipe

- Wall thickness of the Pipe

Inside Diameter of Pipe

To calculate the inside diameter of the pipe we must know how much amount of fluid is being transferred.

Let us say v is the Velocity of fluid flowing per minute, and Q is the quantity of fluid carried per minute.

Whereas the D is the Inside diameter of the pipe.

We know that the quantity of fluid flowing per minute(Q) is = Area×Velocity

Q = (π/4)×D2 × v

From this, we can write the Inside diameter of the pipe (D) = 1.13 √(Q/v)

From this equation, we can evaluate the required pipe inside diameter for the given quantity of fluid to be transferred.

Wall Thickness of the Pipe

Pipe wall thickness is the second most important parameter in the design of a pipe for fluid transport. From the above equation, we get the pipe inside diameter according to the quantity of the fluid to be transferred.

The thickness of the wall (t) in order to withstand the internal pressure exerted by the fluid can be derived with help of a thin cylindrical or thick cylindrical formula that we have discussed previously.

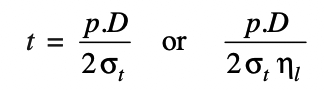

The thin cylindrical formula may be applied to the design of pipe when

- The stress across the section of the pipe is uniform

- The internal diameter of the pipe (D) is more than twenty times its wall thickness (t), i.e. D/t > 20

- The allowable stress (σt) is more than six times the pressure inside the pipe (p), i.e. σt /p > 6

According to the thin cylindrical formula, the wall thickness of the pipe is given by

Where ηl = Efficiency of longitudinal joint

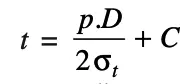

A little consideration will show that the thickness of the wall as obtained by the above relation is too small. Therefore for the design of pipes, a certain constant is added to the above relation. Now the relation may be written as

The value of constant ‘C’, is given in the following table for the different metals such as cast iron, mild steel zinc, copper and lead.

| Material | Cast iron | Mild steel | Zinc and Copper | Lead |

| Constant (C) in mm | 9 | 3 | 4 | 5 |

Materials used for Pipes based on application

- Cast iron Pipes: The use of cast iron pipes is limited to pressures of about 0.7 N/mm2 because of its low resistance to shocks which may be created due to the action of the water hammer. These pipes are best suited for water and sewage systems.

- Wrought iron/Steel pipes: The wrought iron and steel pipes are used chiefly for conveying steam, air and oil.

- Brass pipes: in small sizes, finds use in pressure lubrication systems on prime movers. These are made up and threaded to the same standards as wrought iron and steel pipes. Brass pipe is not liable to corrosion.

- Alloy Steel pipes: The pipes used in petroleum industry are generally seamless pipes made of heat-resistant chrome- molybdenum alloy steel. Such type of pipes can resist pressures more than 4 N/mm2 and temperatures greater than 440°C.

Want to solve a sample problem on the design of Pipe?

Problem Statement: A seamless pipe carries 2400m3 of steam per hour at a pressure of 1.4 N/mm2. The velocity of flow is 30 m/s. Assuming the tensile stress as 40 MPa, find the inside diameter of the pipe and its wall thickness.

Solve this problem and let me know the answers in the comment session below. I will help you with the answers.

Very important note to use pipe design calculations

- In practice, dimensions are not calculated on a rational basis. The standards are evolved on the basis of long practical experience, suitability and interchangeability.

- Indian Boiler regulation has the autharity to approve such designs for boilers and steam pipe systems.

- The calculated dimensions as discussed in this above article do not agree with these standards.

- It is of reader interest only that you should know how to use fundamental principles in determining various dimensions such as wall thickness of pipe, size and number of bolts, flange thickness.

- The rest of the dimensions may be obtained from standard tables or by empirical relations.

Leave a Reply