Hydraulic machines are defined as those machines which convert either hydraulic energy (energy possessed by water) into mechanical energy (which is further converted into electrical energy ) or mechanical energy into hydraulic energy. The hydraulic machines, which convert the hydraulic energy into mechanical energy, are called turbines while the hydraulic machines which convert the mechanical energy into hydraulic energy are called pumps. We discussed different types of Hydraulic turbines in the previous article. To run these Turbines at constant speed can require a governor. We discussed the different types of Governors in an old article. Let us discuss Governing of Turbines with help of a Centrifugal Governor.

Governing of Turbines

The governing of a turbine is defined as the operation by which the speed of the turbine is kept constant under all conditions of working. It is done automatically by means of a governor, which regulates the rate of flow through the turbines according to the changing load conditions on the turbine.

Governing of turbines is necessary as a turbine is directly coupled to an electric generator, which is required to run at a constant speed under all fluctuating load conditions. The frequency of power generation by a generator of a constant number of pairs of poles under all varying conditions should be constant. This is only possible when the speed of the generator, under all changing load conditions, is constant. The speed of the generator will be constant when the speed of the turbine (which is coupled to the generator) is constant.

When the load on the generator decreases, the speed of the generator increases beyond the normal speed (constant speed). Then the speed of the turbine also increases beyond the normal speed. If the turbine or the generator is to run at a constant (normal) speed, the rate of flow of water to the turbine should be decreased till the speed becomes normal. This process by which the speed of the turbine (and hence of the generator) is kept constant under the varying condition of the load is called governing.

Governing of Pelton Turbine (Impulse Turbine)

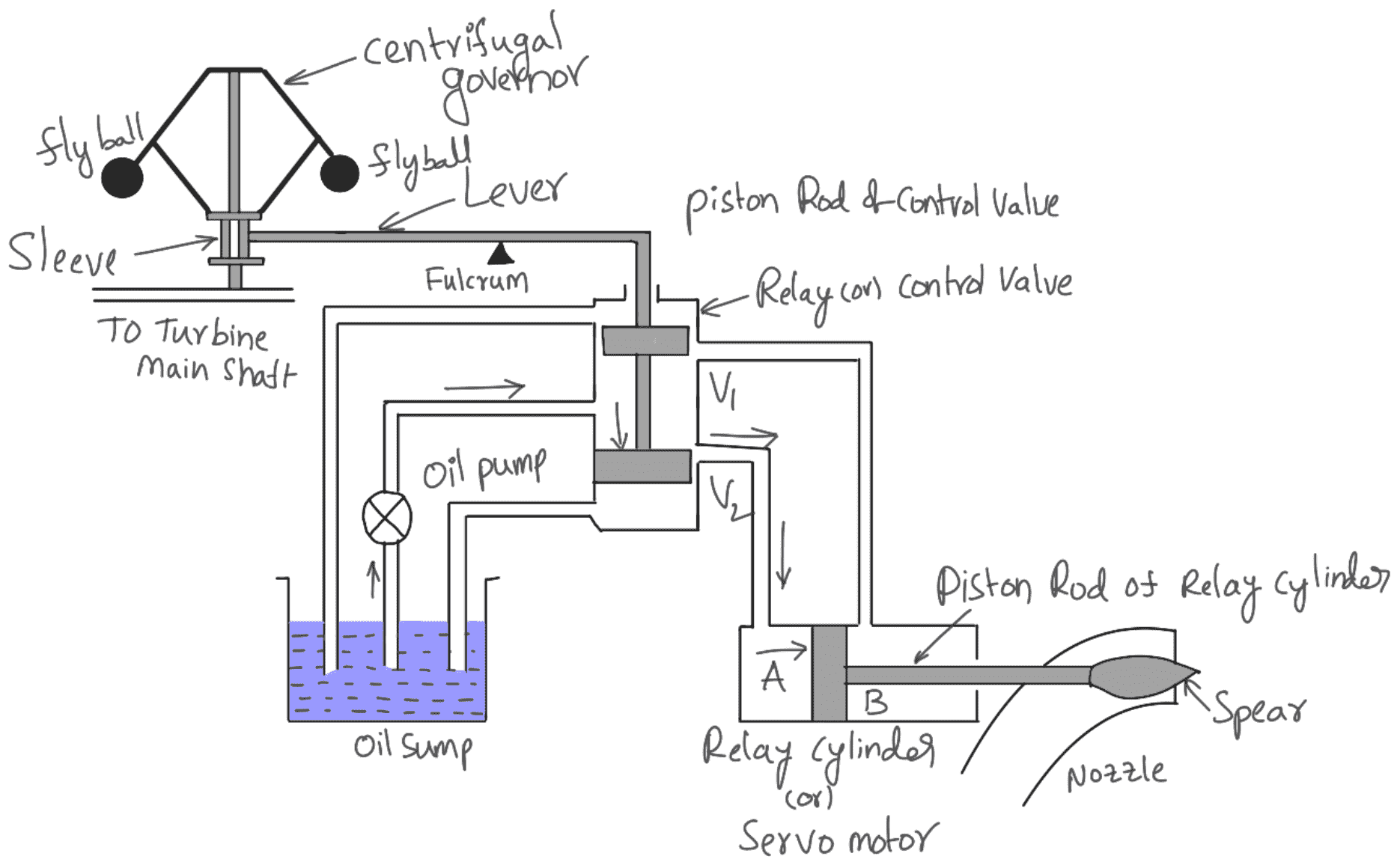

Governing of the Pelton turbine is done by means of an oil pressure governor, which consists of the following parts:

- Oil sump.

- Gearpumpalsocalledoilpump, which is driven by the power obtained from the turbine shaft.

- The Servomotor is also called the relay cylinder.

- The control valve or the distribution valve or the relay valve.

- The centrifugal governor or pendulum is driven by a belt or gear from the turbine shaft.

- Pipes connecting the oil sump with the control valve and the control valve with the servomotor.

- The spear rod or needle.

Construction and Working

- The above schematic diagram shows the position of the piston in the relay cylinder, the position of the control or relay valve and the fly-balls of the centrifugal governor, when the turbine is running at the normal speed.

- When the load on the generator decreases, the speed of the generator increases. This increases the speed of the turbine beyond the normal speed.

- The centrifugal governor, which is connected to the turbine’s main shaft, will be rotating at an increased speed.

- Due to the increase in the speed of the centrifugal governor, the fly-balls move upward due to the increased centrifugal force on them.

- Due to the upward movement of the fly-balls, the sleeve will also move upward.

- A horizontal lever, supported over a fulcrum, connects the sleeve and the piston rod of the control valve.

- As the sleeve moves up, the lever turns about the fulcrum and the piston rod of the control valve moves downward.

- This closes the valve V1 and opens valve V2 as shown in the above schematic diagram.

- The oil, pumped from the oil pump to the control valve or relay valve, under pressure will flow through valve V2 to the servomotor (or relay cylinder) and will exert force on face A of the piston of the relay cylinder.

- The piston along with the piston rod and spear will move towards the right.

- This will decrease the area of flow of water at the outlet of the nozzle.

- This decrease in the area of flow will reduce the rate of flow of water to the turbine which consequently reduces the speed of the turbine.

- When the speed of the turbine becomes normal, the fly-balls, sleeve, lever and piston rod of the control valve come to their normal position as shown in the above schematic diagram.

- When the load on the generator increases, the speed of the generator and hence of the turbine decreases.

- The speed of the centrifugal governor also decreases and hence centrifugal force acting on the fly-balls also reduces.

- This brings the fly-balls in the downward direction.

- Due to this, the sleeve moves downward and the lever turns about the fulcrum, moving the piston rod of the control valve in the upward direction.

- This closes valve V2 and opens valve V1. The oil under pressure from the control valve will move through valve V1 to the servomotor and will exert a force on the face B of the piston.

- This will move the piston along with the piston rod and spear towards the left, increasing the area of flow of water at the outlet of the nozzle.

- This will increase the rate of flow of water to the turbine and consequently, the speed of the turbine will also increase, till the speed of the turbine becomes normal.

This is all about the Governing of Turbines with help of a Centrifugal Governor. Let us know what you think about this artlce in the comment section below.

Leave a Reply