As we discussed earlier What is fatigue failure. The Fatigue refers to the failure of the machine component due to the repeated or cyclic loading. Whereas the fatigue strength or fatigue limit or Endurance limit is used to describe the material property that the cyclic load can be applied to the material without causing the failure.

Fatigue Failure

Consider a wire(Solid) of comparatively less diameter with the length as shown in the figure.

when you try to break it with the bare hands by bending it on both sides as shown in the below figure.

At some point, The solid wire will be definitely broken due to the fractures induced in the solid wire due to the application of the repeated load.

The weakening of a material caused by repeatedly applied loads can be said as the fatigue failure.

See the picture representing where the crack started (Origen) and the complete fatigue zone and the final failure zones.

These cyclic or repeated loads are known as fatigue loads.

Observations

- The maximum stresses caused the fatigue failure, in this case, are much less than the actual strength of the material(Yield stress limit).

- To avoid such failures the shape of the component will play a crucial role to improve the fatigue strength to attain better fatigue life.

- Fillet corners and round holes, etc. can avoid the failures and improve fatigue strength.

Endurance limit or Fatigue limit or Fatigue strength

- Endurance limit ensures the number of cyclic loads that can be acceptable by the component before going to fail by limiting the stress values.

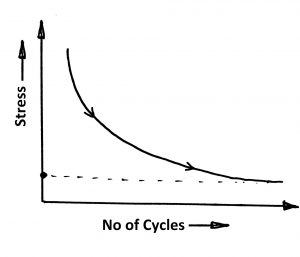

- See the graph between the Stress – No of Cycles (S-N curve)

- As the number of cycles increasing the Stress values for the material will decrease.

- At some point, the stress values can be constant. That means for the infinite number of cycles the limiting stress values will not be changed.

Endurance limit for the different materials

Endurance limit of steel = 0.5 × ultimate tensile strength of the steel

Endurance limit of Iron = 0.4 × ultimate tensile strength of the Iron

Conclusion

Fatigue failure is the most common failure occurring in the mechanical components. we can say over 90% of mechanical failures are fatigue failures.

Couple problems here from a metallurgical standpoint. First, the image of the wire’s fracture surface represents ductile fracture, not brittle. The tell tale river marking, coupled with the edge being stretched, is classic ductile failure. Brittle failure surfaces look like broken glass because the crack nucleation and growth is so energetic.

Also, Al and its alloys do not have a fatigue or endurance limit, so the endurance limit equation is very misleading. This is why bicycle frames made from Al alloys are so grossly overengineered and the tubes are very large compared to a steel frame. The absence of a limit is one of the single defining properties of Al and its alloys, besides it’s ugly microstructure and tenacious oxide layer.

Yes sir, A good observation. I was thought of explaining how the cracks will be induced (from the GIF image). Yes, I agree with the image which represents the fatigue fracture is looking like a ductile failure surface.

Yes, I agree both Aluminum and copper also do not have a distinct Endurance limit. These both materials will eventually fail even from small stress amplitudes. Instead of the endurance limit, we use the Endurance strength for these two materials.

Thanks for correcting on this. Keep reading our articles. I appreciate your interest in Extrudesign.com

Nice explanation

Thus… what’s the difference?