A clutch is a machine member used to connect a driving shaft to a driven shaft so that the driven shaft may be started or stopped at will, without stopping the driving shaft. The use of a clutch is mostly found in automobiles. Let us discuss different types of Clutches in this article.

Clutch

A clutch is a machine member used to connect a driving shaft to a driven shaft so that the driven shaft may be started or stopped at will, without stopping the driving shaft. The use of a clutch is mostly found in automobiles. A little consideration will show that in order to change gears or to stop the vehicle, it is required that the driven shaft should stop, but the engine should continue to run. It is, therefore, necessary that the driven shaft should be disengaged from the driving shaft. The engagement and disengagement of the shafts is obtained by means of a clutch which is operated by a lever.

Different types of Clutches

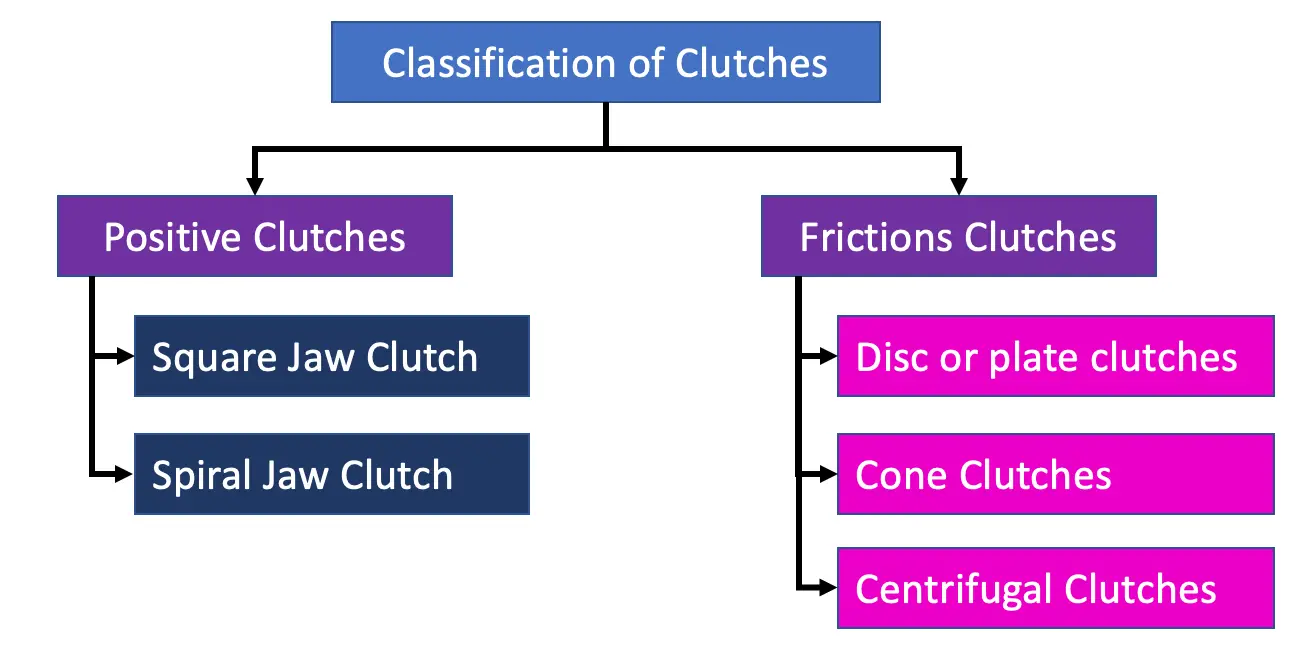

There are two main types of clutches commonly used in engineering practice:

- Positive clutches

- Friction clutches

These are further classified as follows

The positive clutches are used when a positive drive is required. The simplest type of a positive clutch is a jaw or claw clutch. Positive clutches are classified as

- Square Jaw Clutch

- Spiral Jaw Clutch

A friction clutch has its principal application in the transmission of power of shafts and machines which must be started and stopped frequently. Though there are many types of friction clutches, we only discussed the following important from the mechanical engineer’s point of view:

- Single Disc or plate clutches

- Multi Disc or plate clutches

- Cone clutches

- Centrifugal clutches

The following schematic tree helps us identify the Different Types of Clutches

Let us briefly discuss these different types of clutches.

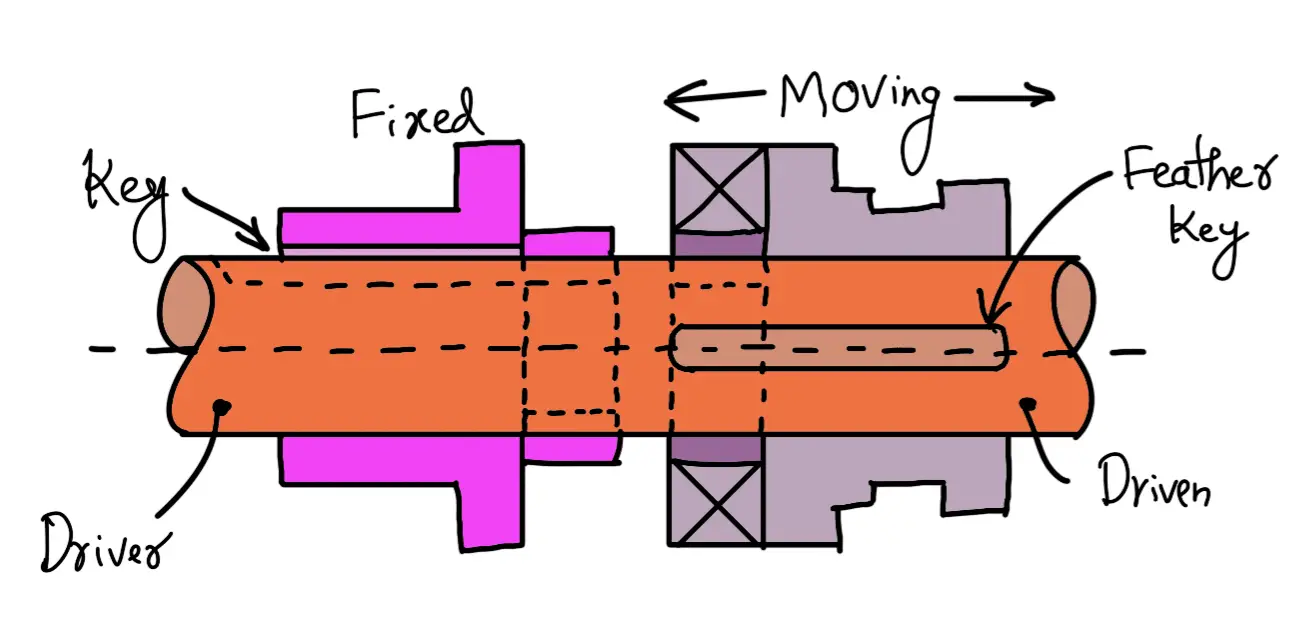

1. Positive Clutches

The positive clutches are used when a positive drive is required. The simplest type of a positive clutch is a jaw or claw clutch. The jaw clutch permits one shaft to drive another through direct contact with interlocking jaws. It consists of two halves, one of which is permanently fastened to the driving shaft by a sunk key. The other half of the clutch is movable and it is free to slide axially on the driven shaft, but it is prevented from turning relatively to its shaft by means of a feather key. The jaws of the clutch may be of the square type or of the spiral type.

Following is the Square Jaw Clutch.

A square jaw type is used where engagement and disengagement in motion and under load is not necessary. This type of clutch will transmit power in either direction of rotation.

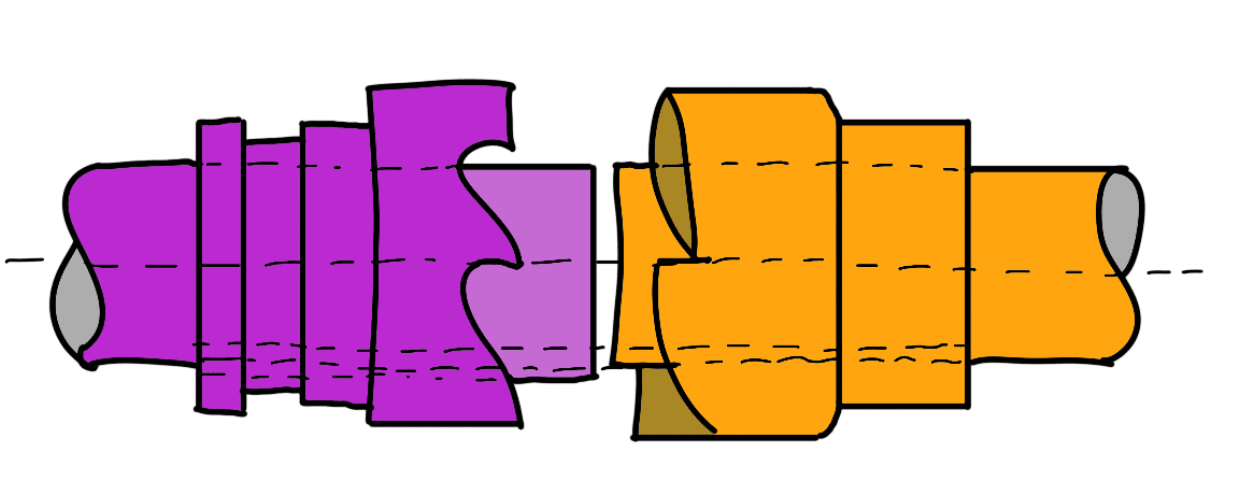

Following is the Spiral Jaw Clutch.

The spiral jaws may be left-hand or right-hand because power transmitted by them is in one direction only. This type of clutch is occasionally used where the clutch must be engaged and disengaged while in motion. The use of jaw clutches is frequently applied to sprocket wheels, gears, and pulleys. In such a case, the non-sliding part is made integral to the hub.

2. Friction Clutches

A friction clutch has its principal application in the transmission of power of shafts and machines which must be started and stopped frequently. Its application is also found in cases in which power is to be delivered to machines partially or fully loaded. The force of friction is used to start the driven shaft from rest and gradually bring it up to the proper speed without excessive slipping of the friction surfaces. In automobiles, a friction clutch is used to connect the engine to the drive shaft.

In operating such a clutch, care should be taken so that the friction surfaces engage easily and gradually bring the driven shaft up to proper speed. The proper alignment of the bearing must be maintained and it should be located as close to the clutch as possible.

It may be noted that:

- The contact surfaces should develop a frictional force that may pick up and hold the load with reasonably low pressure between the contact surfaces.

- The heat of friction should be rapidly dissipated and the tendency to grab should be at a minimum.

- The surfaces should be backed by a material stiff enough to ensure a reasonably uniform distribution of pressure.

During the operation of a clutch, most of the work done against frictional forces opposing the motion is liberated as heat at the interface. It has been found that at the actual point of contact, a temperature as high as 1000°C is reached for a very short duration (i.e. for 0.0001 seconds). Due to this, the temperature of the contact surfaces will increase and may destroy the clutch.

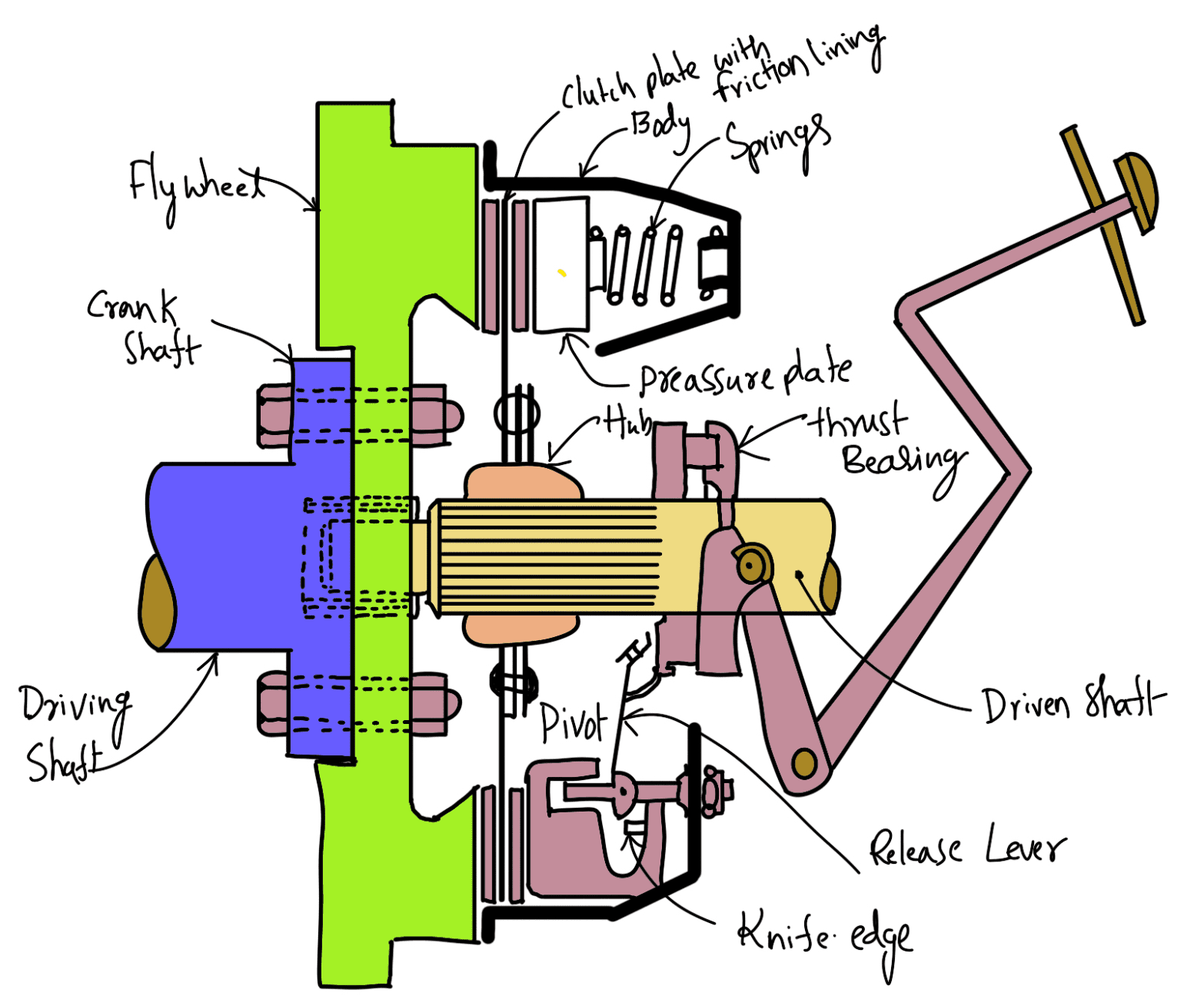

Single Disc or Plate Clutch

A single disc or plate clutch, as shown in the following schematic diagram, consists of a clutch plate whose both sides are faced with a frictional material (usually of Ferrodo). It is mounted on the hub which is free to move axially along the splines of the driven shaft. The pressure plate is mounted inside the clutch body which is bolted to the flywheel.

Both the pressure plate and the flywheel rotate with the engine crankshaft or the driving shaft. The pressure plate pushes the clutch plate towards the flywheel by a set of strong springs which are arranged radially inside the body. The three levers (also known as release levers or fingers) are carried on pivots suspended from the case of the body.

These are arranged in such a manner that the pressure plate moves away from the flywheel by the inward movement of a thrust bearing. The bearing is mounted upon a forked shaft and moves forward when the clutch pedal is pressed.

When the clutch pedal is pressed down, its linkage forces the thrust release bearing to move in towards the flywheel and press the longer ends of the levers inward. The levers are forced to turn on their suspended pivot and the pressure plate moves away from the flywheel by the knife edges, thereby compressing the clutch springs.

This action removes the pressure from the clutch plate and thus moves back from the flywheel and the driven shaft becomes stationary. On the other hand, when the foot is taken off from the clutch pedal, the thrust bearing moves back by the levers. This allows the springs to extend and thus the pressure plate pushes the clutch plate back towards the flywheel.

The axial pressure exerted by the spring provides a frictional force in the circumferential direction when the relative motion between the driving and driven members tends to take place. If the torque due to this frictional force exceeds the torque to be transmitted, then no slipping takes place and the power is transmitted from the driving shaft to the driven shaft.

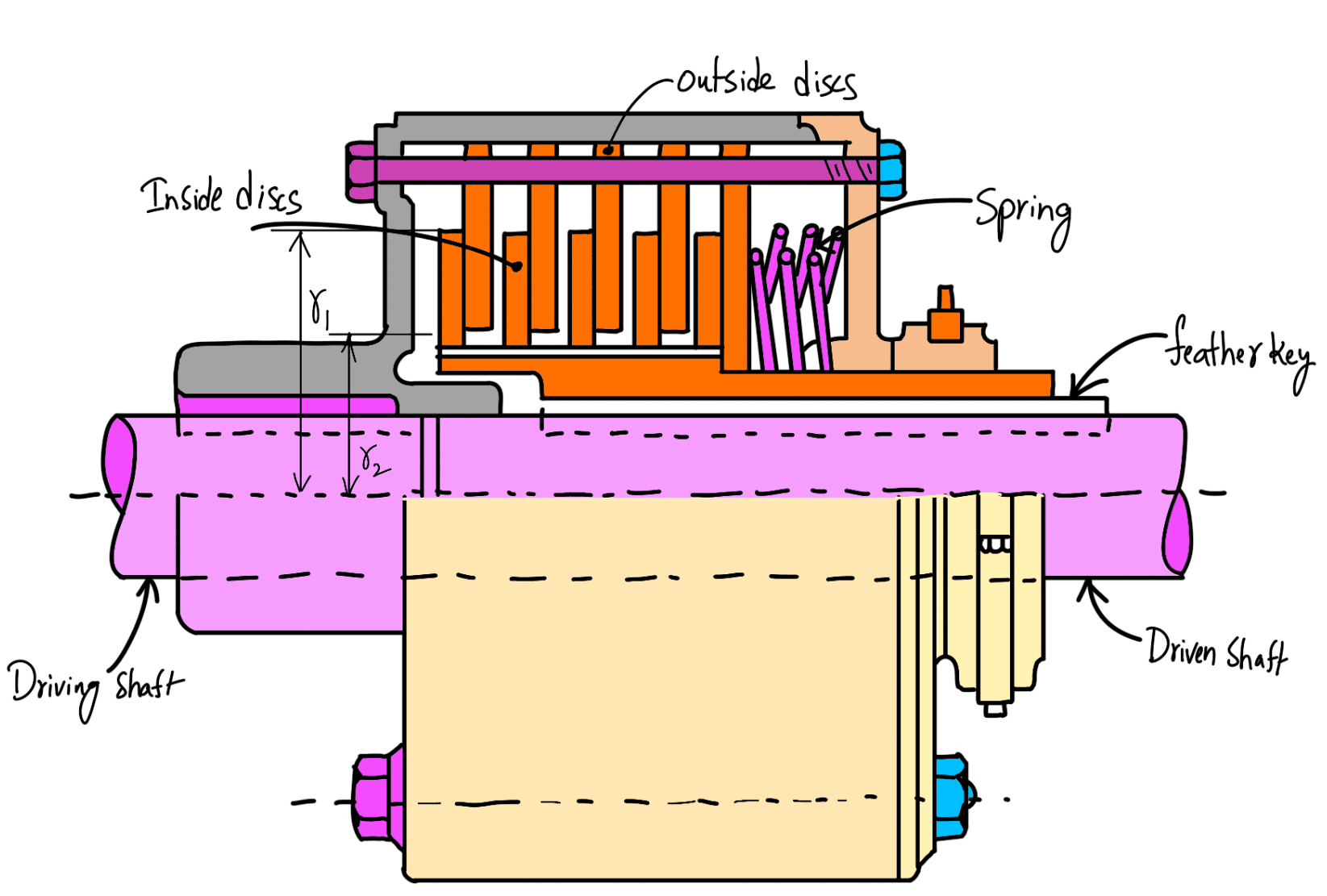

Multiple Disc Clutch

A multiple-disc clutch, as shown in the following figure, may be used when a large torque is to be transmitted. The inside discs (usually of steel) are fastened to the driven shaft to permit axial motion (except for the last disc).

The outside discs (usually of bronze) are held by bolts and are fastened to the housing which is keyed to the driving shaft. The multiple disc clutches are extensively used in motor cars, machine tools, etc.

Read more about Disc or Place clutch here…

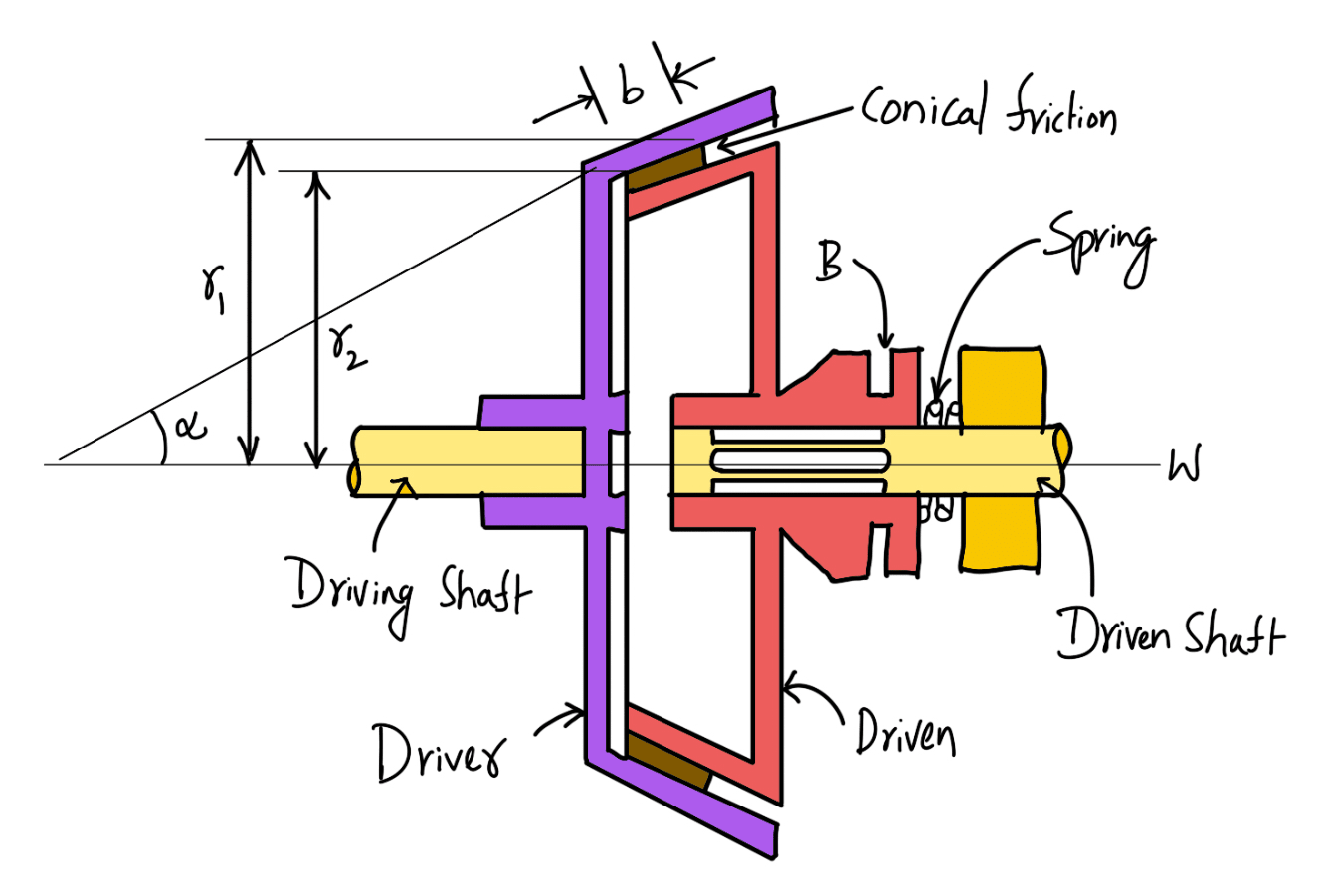

Cone Clutch

A cone clutch, as shown in the following figure, was extensively used in automobiles, but nowadays it has been replaced completely by the disc clutch. It consists of one pair of friction surfaces only. In a cone clutch, the driver is keyed to the driving shaft by a sunk key and has an inside conical surface or face that exactly fits into the outside conical surface of the driven.

The driven member resting on the feather key in the driven shaft may be shifted along the shaft by a forked lever provided at B, in order to engage the clutch by bringing the two conical surfaces in contact. Due to the frictional resistance set up at this contact surface, the torque is transmitted from one shaft to another. In some cases, a spring is placed around the driven shaft in contact with the hub of the driven. This spring holds the clutch faces in contact and maintains the pressure between them, and the forked lever is used only for disengagement of the clutch.

The contact surfaces of the clutch may be metal-to-metal contact, but more often the driven member is lined with some material like wood, leather, cork asbestos, etc. The material of the clutch faces (i.e. contact surfaces) depends upon the allowable normal pressure and the coefficient of friction.

Read More about the Design of Cone clutch here…

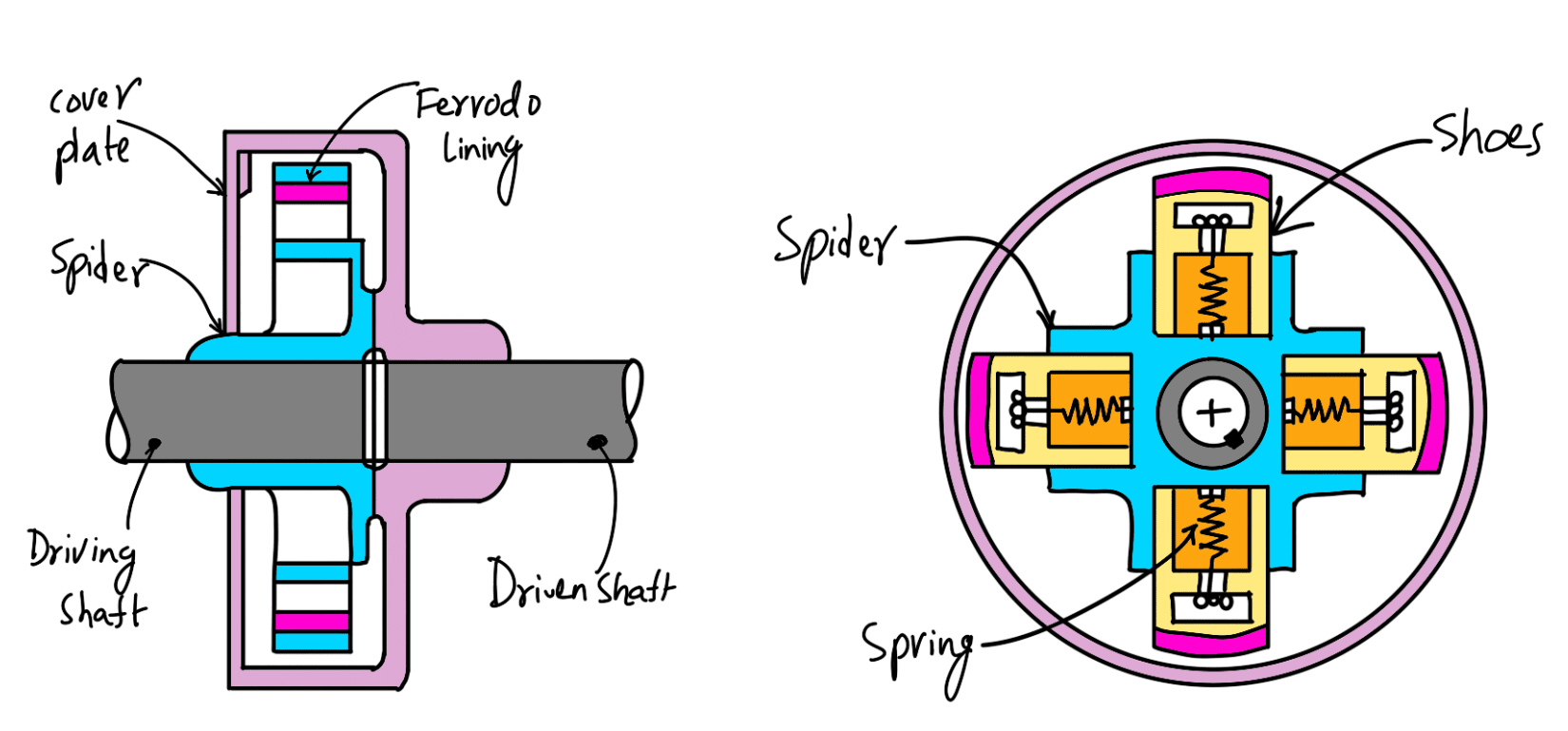

Centrifugal Clutch

The centrifugal clutches are usually incorporated into the motor pulleys. It consists of a number of shoes on the inside of a rim of the pulley, as shown in the following figure. The outer surface of the shoes are covered with a friction material. These shoes, which can move radially in guides, are held against the boss (or spider) on the driving shaft by means of springs.

The springs exert a radially inward force which is assumed constant. The weight of the shoe, when revolving causes it to exert a radially outward force (i.e. centrifugal force). The magnitude of this centrifugal force depends upon the speed at which the shoe is revolving. A little consideration will show that when the centrifugal force is less than the spring force, the shoe remains in the same position as when the driving shaft is stationary, but when the centrifugal force is equal to the spring force, the shoe is just floating. When the centrifugal force exceeds the spring force, the shoe moves outward comes into contact with the driven member, and presses against it. The force with which the shoe presses against the driven member is the difference of the centrifugal force and the spring force. The increase in speed causes the shoe to press harder and enables more torque to be transmitted.

Read More about the Centrifugal Clutch here…

Material for Friction Surfaces

The material used for lining of friction surfaces of a clutch should have the following characteristics:

- It should have a high and uniform coefficient of friction.

- It should not be affected by moisture and oil.

- It should have the ability to withstand high temperatures caused by slippage.

- It should have high heat conductivity.

- It should have high resistance to wear and scoring.

The materials commonly used for lining friction surfaces and their important properties are shown in the following table.

| Material of friction surfaces | Operating condition | Coefficient of friction | Maximum operating temperature (°C) | Maximum pressure (N/mm2) |

| Cast iron on cast iron or steel Cast iron on cast iron or steel Hardened steel on Hardened steel Bronze on cast iron or steel Pressed asbestos on cast iron or steel Powder metal on cast iron or steel Powder metal on cast iron or steel | dry In oil In oil In oil dry dry In oil | 0.15 – 0.20 0.06 0.08 0.05 0.3 0.4 0.1 | 250 – 300 250 – 300 250 150 150 – 250 550 550 | 0.25– 0.4 0.6 – 0.8 0.8 – 0.8 0.4 0.2 – 0.3 0.3 0.8 |

Friction Clutch Applications

The Automobile industry is one of the major applications for friction clutches widely.

And also where we use diesel engines, there is a possibility of usage of the clutch. But there are different clutches also available as well. Such as turbo clutch. So this can be a friction clutch or any other kind of clutch based on customer preference.

This is all about the different types of clutches. Let us know what you think about this article in the comment section below.

Leave a Reply