When two equipment (Driver and driven) need to coupled together, then they need to be aligned properly to couple together. Installing the two equipment with 100% alignments is not possible. These misalignments can be accommodated by the special member called coupling. There are two different types of couplings. Flexible couplings and rigid couplings. These coupling will be able to accommodate these misalignments. So let’s see what are the different Shafts misalignment.

Shafts Misalignment

As we said the shafts Misalignment occurs when we need to couple two equipment together. The major misalignments are Axial, radial(Parallel), and angular misalignments.

Axial Misalignment

When there is a variation in axial distance between the shafts of the driving and driven machinery then it is said as the Axial misalignment.

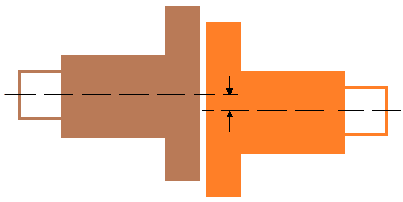

Radial Misalignment Or Parallel Misalignment or Offset Misalignment

When there is a difference between the axis of the two shafts said as the radial misalignment or the parallel misalignment or offset misalignment.

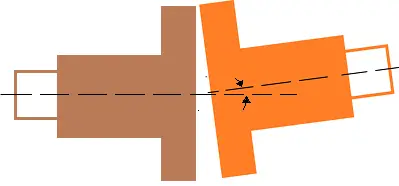

Angular Misalignment

When the two axes of the two shaft are not parallel and intersecting at some point then those are called as the angular misalignment.

What causes the Shafts misalignment?

Even if we install any equipment with perfect alignments, the misalignment can occur due to the strain due to the continuous operations of the equipment. Following are some of the causes of the Shafts Misalignment.

- Over time, foundations or base-plates can settle to lower positions, causing settling misalignment gradually.

- Thermal expansion can cause one piece of equipment to move proportionately to another, causing relative movement misalignment. [Different materials expand at different rates when they exposed to different temperatures] Thermal growth must be accounted for when equipment normally operates above ambient temperature.

- The manufacturing effects in the coupling (Non-eccentric bores in the equipment) also causes the misalignments.

- The initial high torque caused during startup of a prime mover can force shafts out of alignment, causing torsional movement misalignment.

- Installation errors by a human during the following an installation procedure.

These are some of the shafts misalignment causes.

What is the effect of these shafts misalignment?

- The first thing we can say the vibration. There is over 50% to 70% of all vibration problems in machines are caused by misalignment.

- As we speak of vibration, noise also arises due to the misalignments.

- Due to the misalignments, vibration the lifespan of the equipment will be shortened.

- unplanned maintenance due to the failure of the equipment.

These are the certain reason that we need to use some flexible couplings to accommodate the misalignments to secure the equipment from damages.

Conclusion

We have discussed what are the misalignments, and why they occur and what are the effects of misalignments. If you have any further thoughts on this topic, let us know in the comment section below.

Leave a Reply