In the previous article, we have discussed the Functional requirement of coupling and the coupling classification. In this article, we are going to discuss the different types of Rigid couplings.

Rigid couplings

Rigid Couplings are used to connect two shafts which are perfectly aligned. Following are the different types of rigid couplings.

- Sleeve coupling

- Muff coupling

- Splined coupling

- Clamp or split-muff or compression coupling

- Flange coupling

Sleeve or Muff Coupling

Sleeve or muff coupling is the simplest type of rigid coupling. It is a hollow cylinder with an inner diameter which will make an engineering fit with the drive shaft and the driven shaft. There is a keyway in the sleeve to couple the drive shaft with the sleeve and to the driven shaft with the help of a gib headed key. And there are some Allen screws are also provided in the sleeve to lock the key in position.

This rigid sleeve or muff coupling is used when the two shafts are perfectly aligned. For high power transmission or high speeds, these sleeves coupling are not recommended.

The outer diameter of the sleeve should be 2 times the diameter of the shaft + 13mm additional on diameter and length of the sleeve should be 3.5 times the shaft diameter.

There is an important thing to note that to install this sleeve or muff coupling, the drive shaft or the driven shaft position needs to be changed.

Spline Coupling

As we can see the sleeve coupling with a keyway above, this spline coupling is similar as the sleeve or muff coupling but instead of the keyway, we have a number of slots on the inner diameter of the sleeve as shown in the below picture.

The sleeve inner side and the shaft outer side will have the same profile slots with the same number of them.

What are the advantages of spline coupling?

There are certain advantages for the spline coupling over the keyed connection. Those are listed below.

- Equally distributed load along the circumference.

- Small installation size.

- Transfer of rotational concentricity.

- A little Angular misalignments accommodation.

- Can allow for radial misalignment accommodation.

- Suitability for high rotation speeds.

- Relatively insensitive to overloading.

Clamp or split-muff or compression coupling

The above Sleeve or Muff coupling is a single mechanical part. whereas this clamp or compression or Split miff coupling is made into two pieces and bolted together with the mild steel studs or bolts.

There is one advantage over the sleeve or muff coupling is that to install this split muff coupling, no need to change the positions of the drive shaft or the driven shaft.

This coupling can be used for heavy duty and moderate speed applications.

Flange coupling

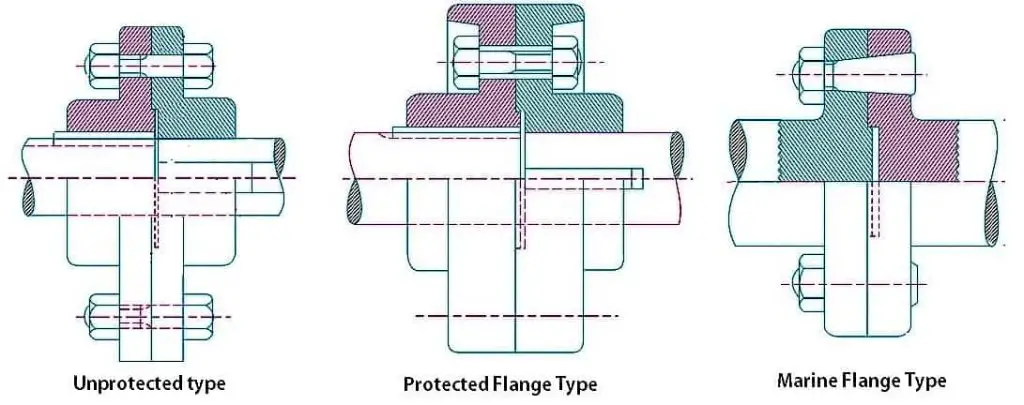

A coupling having two separate flange hubs with the keyed fit to the individual shaft. These two flanges will be joined together with the bolted pattern. On one flange there will be projected part called pilot or spigot on the other flange there will be a corresponding recess to make the perfect alignment for both flanges.

This Flange coupling can be helpful to bring the shaft to maintain the alignment and also capable to adopt the heavy loads. so it will be used on the large shafts.

There are three different types of flange couplings.

- Unprotected type flange coupling (The bolt and nuts are protruded outside)

- Protected type flange coupling ( (The protruded bolt and nuts are protected by circumferential flange)

- Marine type flange coupling (Flanges integrated into the shaft)

This is all about the Rigid couplings. Check out what are the different flexible couplings here.

Conclusion

We have discussed the rigid couplings types with advantages and the drawbacks with the help of neat pictures. If you have any further thoughts on this topic, let us know in the comment section below.

Leave a Reply