A shaft coupling is a mechanical element that connects the two shafts together to transmit the torque from one end to the other by accommodating the misalignment. In the previous article, we have discussed the Functional requirement of coupling, coupling classification, and Rigid Coupling types. In this article, we are going to discuss the different Flexible coupling types.

Flexible Coupling types

As we have mentioned already that the flexible couplings are used to transmit the torque while compensating for the misalignment between the driver and driven end and also accommodate the axial movement.

The classification of flexible couplings may be depending on the criteria that the flexibility of the coupling can be achieved by material flexibility or mechanical flexibility. Following are the different types of flexible couplings in general. where we listed the most common and important types of flexible couplings that the different industries used.

- Gear coupling

- Old-ham coupling

- Disc Coupling

- Grid Couplings

- Diaphragm coupling

- Fluid Couplings

- Torsional couplings

- Bushed pin type coupling

- Universal coupling

Material flexibility is achieved due to material deformation. For example an Elastic coupling or the torsional coupling, the flexible element is an elastic element that provides flexibility by deforming itself.

There are other examples for material flexibility is that disc couplings and diagram coupling. In these flexible couplings, thin metallic sheets are used to flex and achieve flexibility. We can classify these as material flexible elements. But in some cases, we classify them as separate types of flexible elements called Metallic Flexibility or Metallic Flexible element coupling

Whereas Mechanical flexibility can be achieved by parts of the flexible coupling roll or slide or tilt over the other component’s surface. In this case, let us take an example of the gear coupling which provides flexibility by mechanical.

Let us discuss the above-listed gear couplings in detail and also see where these couplings are used.

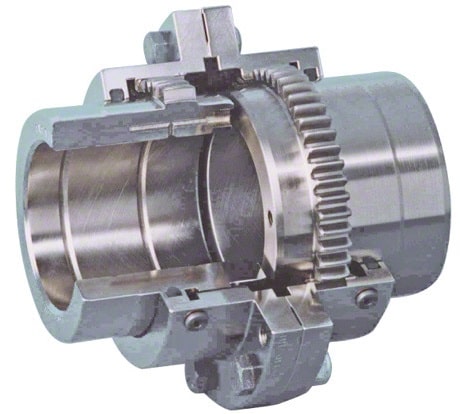

1. Gear coupling

Gear Couplings are usually torsionally rigid couplings. These can transmit the highest amount of torque from one end to the other end.

These gear couplings can be designed in a completely flexible model where it can accommodate the parallel misalignment and a flexible-rigid model where it can not accommodate the parallel misalignment.

In a complete Flexible gear coupling model, both sides of the gear coupling come with a sleeve(Internal gear tooth) and hub with an external gear tooth. Which will provide a double flexible engagement for all three misalignments(Axial Parallel, Angular).

In the Flexible- rigid gear coupling model, only one side will be having a sleeve with an inner gear tooth and the hub with an external gear tooth, and on the other side with a rigid flange hub. Which will provide only a single flexible engagement for the two misalignments(Axial, angular). Parallel misalignment is not possible in this model.

Gear Coupling Application: Industrial Applications, Turbomachinery

2. Old-ham coupling

Old-ham coupling usually provides a huge amount of parallel misalignment. It consists of three members. There is a floating member trapped in between the other two members by means of 90° grooves on both sides o the floating member. Check out the picture of the Old -ham coupling.

Old-ham coupling Application: Robotics, servo in addition to the printer and copy machines

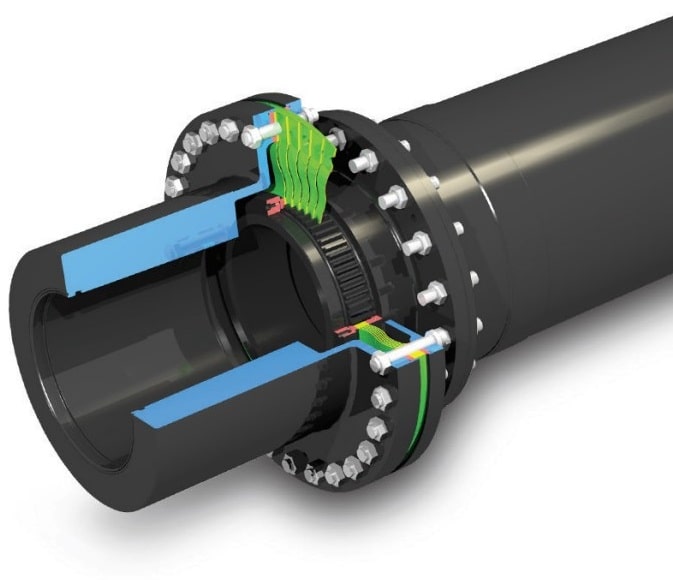

3. Disc Coupling

The disc coupling is having a thin sheet of discs laminated as the main part of the coupling for the flexibility to accommodate the misalignments.

Check out the above disc coupling picture. it consists of two hubs on each side and a spacer at the middle joined by the discs on both sides.

Disc Coupling Application: Hydrostatic application (Gearbox to hydraulic pumps), Turbomachinery

4. Grid Couplings

Grid couplings are very good at dampening vibrations. These Grid couplings have some quite similar components as the gear couplings except the gear meshing. the hubs will have the slots and these slots will mesh with the steel spring. Check the picture of a grid coupling.

These grid couplings cannot accommodate the parallel misalignments. Minimal angular misalignments can be provided and a good amount of axial misalignment can be accommodated. Grid coupling can transmit high torques because of its metallic design.

Grid Coupling Application: Industrial application where a coupling needs to absorb the shock loads.

5. Diaphragm coupling

Diaphragm coupling also uses thin sheets as a flexible element like disc coupling. The outer diameter side of the diaphragm will be bolted with the hub and the inner side diameter portion of the diaphragm disc will be fitted into the slots of the spool portion. On the other end of the spool(spacer) will be again joined by a diaphragm disc with a hub.

Diaphragm couplings can accommodate all three misalignments. It can accommodate more range of misalignment axially.

Diaphragm Coupling Application: Turbomachinery

6. Fluid Couplings

The fluid coupling also is known as the hydraulic couplings. There will be two turbines (Impellers) covered by housing to fill the fluid. One impeller will be installed on the driveshaft and the other will be on the driven shaft. These two impellers will be connected with the fluid supported by the housing. as the input shaft rotates the input impeller also rotates. as a result, the fluid will transmit the torque slowly into the driven impeller as the speed increases. This Fluid coupling will be used as the mechanical clutch.

Fluid Coupling Application: Automobiles, marine, and industrial machine drives as a mechanical clutch.

7. Torsional couplings

Torsional couplings are mostly to accommodate the torsional vibration. Most of these are rubber coupling where it can dampen the vibrations and also accommodate the misalignments. Also, spring torsional couplings are also available as torsional couplings.

Torsional couplings Applications: Diesel engine generators, marine application.

8. Bushed pin type coupling

It is a simple type of coupling with two flanges bolted with the help bolt and a nut covered by a bush made up of rubber. Check the Bushed pin-type coupling picture. These couplings are torsionally rigid and also accommodate all three misalignments. Because of their simple design, these are less expensive.

Bushed pin-type coupling Application: Industrial applications.

9. Universal coupling

Mostly known as the Universal joint and it is well known to us. It is a linkage consisting of two yokes connected by a spider.

Check out the gif image of a universal joint. As you can see it can accommodate massive angular misalignments. It is mainly used for the lengthy shaft linings supported by bearings.

Universal Coupling Applications: automobiles, Aircraft application, Driveshaft, Stone crushers, Control mechanisms, Belt conveyors, Metal forming machinery, Tool drivers

These are the different flexible coupling types and their application.

Let us list the above applications once again in one place to see what are the common couplings that we used across many industries.

Flexible Coupling Applications

- In industrial application we can use the Gear coupling, disc coupling, grid couplings, bushed pin type coupling.

- Turbo machinary application we can use gear couplings, disc couplings, diaphram couplings

- Hydrostatic pump application we can uuse Disc couplings

- In robotics and minature applications such as printer machines, we can use the old ham couplings.

- All the marine drives, diesel generator applications, where ever Diesel engine is driveing, we need to use the torsional coupling/ elastromer couplings.

- The universial coupling will be used in Automobiles, Aircraft application, Driveshaft, Stone crushers, Control mechanisms, Belt conveyors, Metal forming machinery, Tool drivers.

- The Fluid coupling will be used if there is a necessity of mechanical clutch. Automobiles, marine, and industrial machine drives are some of the applications for fluid couplings.

How to Select a Flexible coupling for any application?

To select any above couplings following are the necessary steps that will be considered.

- Rated input Torque: The coupling must be able to transmit the maximum torque that need to be transmitted along with the safety factor.

- Rated Speed: The maximum speed of the drive should be acceptable by the coupling.

- Misalignments: the maximum misalignments should be compensated by the coupling while working at maximum speed or maximum torque.

- Installation: Based on the customer requirement the coupling should provide above 3 paramters with specified installation space. Sometimes the space between driver and driven is very less, then there will be need of the closed-coupling, in some other application the driver and driven equipments are very far, tthere we need a free standing coupling with spacer.

- Stiffness: This will be the most critical part of the coupling paramter to select. where we might need an analysis for the shaft system to ensure the system is free from the resonance during the working speeds. Also to check if any gearing sound produced due to the vibratory torque from the prime mover. the stiffness of the coupling will be helpfull to shift the natural frequency of the system away from the critical speed.

Apart from these parameters, there are some other parameters as well, that might into play while considering a particular application.

Conclusion

We have discussed the Flexible coupling types with their applications with the help of neat pictures. If you have any further thoughts on this topic, let us know in the comment section below.

Coupling is mainly used in Automation and Welding Industries. There are two main categories of coupling: Material and Mechanical. Material coupling is that which do not require lubrication while the mechanical coupling is that which require lubrication. Example of material flexing couplings is: jaw, sleeve, tire, disc, etc. Example of mechanical flexing coupling is gear coupling, grid coupling, roller chain coupling, etc.

You should add our Twin Spring Couplings to your list

As flexible and can handle the same amount of torque as a universal joint but as torsionally rigid as jaw couplings but the main advantage over these other kinds of coupling, no internal components like bearings and spider inserts that wear and need to be replaced.

Offered in the same shaft sizes and splines, ake it an easy retro fit