The Wilson-Hartnell Governor is spring controlled load governor categorised under the centrifugal governors. We have discussed the Hartung Governor and Hartnell governor in the previous articles, which are also the spring-loaded governors with which have different construction and working principle from this type of governor.

Wilson-Hartnell Governor

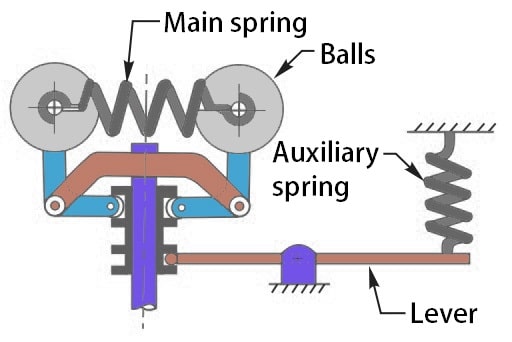

In this type of governor, there is no need for the load on the sleeve to increase the speed of the balls required to lift the sleeve on the spindle. Instead, we will have the mainspring attached between the fly balls and also another auxiliary spring to the sleeve.

Wilson-Hartnell Governor is also working the same as the Hartnell governor or Hartung governor instead of one spring mechanism either on the sleeve or the fly balls respectively, two spring mechanisms (one spring load on the sleeve, another spring load on the fly balls) were used.

Construction and Working of Wilson-Hartnell Governor

As we mentioned there were two springs were used to govern the fuel quantity. Apart from these spring mechanisms, this Governor is working on the Centrifugal forces working principle.

Out of the two springs connected in the mechanism. One is attached between the flyballs called the mainspring. The second spring is attached for the sleeve with help of the lever about a pivot. As you can see the schematic diagram of the Wilson-Hartnell Governor below.

- The mainspring is may be considered of two equal parts each belonging to both the balls as you can see from the above schematic diagram.

- This mainspring will experience the tension force due to the centrifugal force when the engine is rotating at the high speed.

- The auxiliary spring is attached to the sleeve with the help of a lever mechanism. which will also experience the tension forces during the engine high speeds.

- This auxiliary spring attached to the sleeve is helpful to adjust the nominal working(Equilibrium) speed of the engine.

- While the engine is running at higher speeds the mainspring will elongate and lift the sleeve with the help of the bell crank lever against the load supported by the auxiliary spring attached to the sleeve.

- so that the sleeve movement will control the fuel supply passage. at engine higher speeds it will pass less fuel amount and in low speeds, due to load on the engine, it will supply the more amount of the fuel.

This is how the Wilson-Hartnell Governor works to govern the fuel supply and regulates the mean speed of the engine when there is a variation in the load.

Conclusion

We have discussed the Wilson-Hartnell Governor, its construction and working principle. If you have any further thoughts on this topic, let us know in the comment section below.

Leave a Reply