In transporting fluids such as water, steam, gases, oil, and chemicals, pipes are used. Designing a pipe with basic parameters such as the diameter and thickness of the pipe is explained in the previous article. While designing these pipes the length can be limited, there must be a way to join them to achieve suitable lengths for particular applications. So within this article, we are going to discuss the most common types of pipe joints.

Different Pipe Joints

As we mentioned the pipe lengths are limited and to achieve suitable lengths we need a pipe joint to join them. Some of the most common types of pipe joints are discussed below.

- Socket or a coupler Joint

- Nipple Joint

- Union Joint

- Spigot and Socket Joint

- Expansion Joint

- Flanged Joint

- Hydraulic pipe Joint

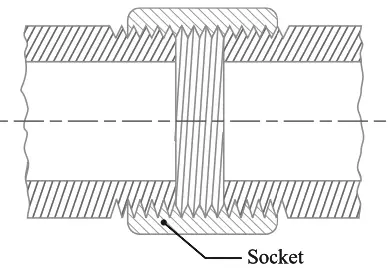

Socket or a coupler Joint

Socket or coupler joint is the most common method of joining pipes. In this pipe joint, the joint is made by a socket or a coupler as shown above figure. A socket is a small piece of pipe with an internal thread as shown in the above figure. The socket is screwed on halfway on the internally threaded portion for one of the pipes. The other half portion of the socket is screwed on the other pipe as exactly shown above.

Jute or Hemp is a material that acts as a seal to prevent leakage. This jute or hemp is wound around the threads at the end of each pipe. Socket joint or coupler joint is mostly used for pipes carrying water at very low pressure and where the overall smallness of pipe joint size is most essential.

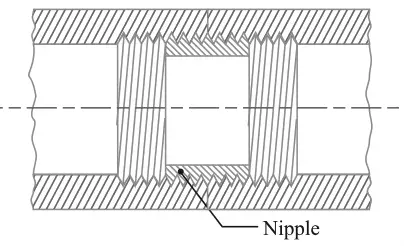

Nipple Joint

The nipple Joint is made up of a nipple which is a small piece of pipe threaded outside that is screwed in the internally threaded end of each pipe, as shown in the above figure.

The main disadvantage of this Nipple joint is that it reduces the cross-section area of flow at the joint due to the nipple.

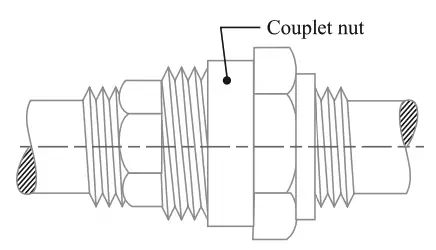

Union Joint

In fewer applications, it is required to disengage the pipes. To disengage pipes joined by a socket, it is necessary to unscrew the pipe from one end. This is sometimes inconvenient when pipes are long.

The union joint, as shown in the above figure, provides the facility of disengaging the pipes by simply unscrewing a coupler nut. This pipe joint is preferred, where there is the necessity of disengagement of the pipe is required.

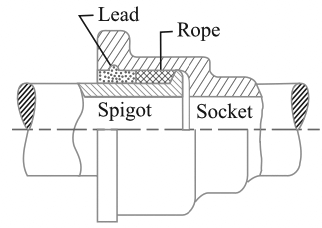

Spigot and Socket Joint

In some applications, we need to bury the pipes in the earth for special reasons, in those cases this spigot and socket joints are used. Some pipelines are laid straight as far as possible. One of the important features of this joint is its flexibility as it adapts itself to small changes in level due to settlement of earth which takes place due to climate and other conditions.

In this type of spigot and socket joint, the spigot end of one pipe fits into the socket end of the other pipe. The remaining space between the two is filled with a jute rope and a ring of lead. When the lead solidifies, it is caulked tightly inside the space between the socket and spigot as shown above figure.

Expansion Joint

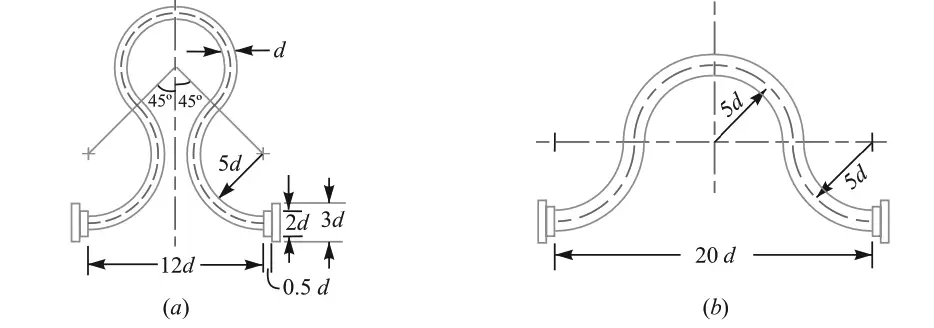

Expansion joints are usually preferred to join the pipes where they carry steam at very high pressure. This joint helps the steam pipes to take up the expansion and contraction of the pipeline due to temperature changes. To allow for a change in length, steam pipes are not rigidly clamped but supported on rollers. The rollers may be arranged on wall brackets, hangers or floor stands.

As shown above, The expansion bends (a) and (b) are useful in a long pipeline. These pipe bends will spring in either direction and readily accommodate themselves to small movements of the actual pipe ends to which they are attached.

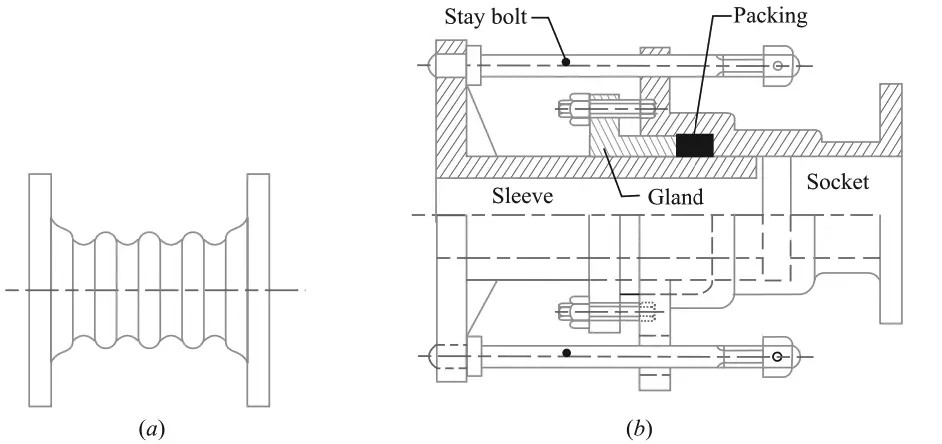

The above-shown figure (a) is the copper corrugated expansion joint, it is used on short lines and is satisfactory for limited service. And the expansion joint (b) as shown above picture also known as gland and stuffing box arrangement is the most satisfactory when the pipes are well supported and cannot sag.

Flanged Joint

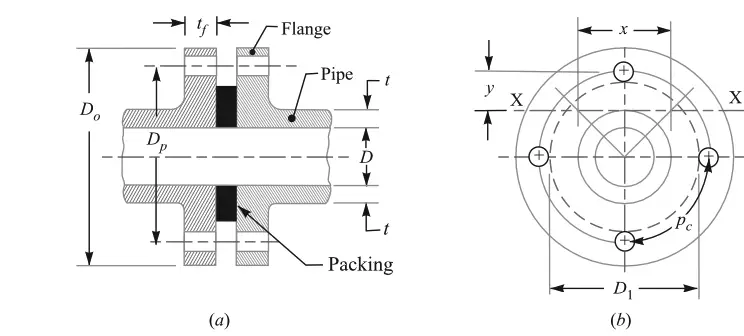

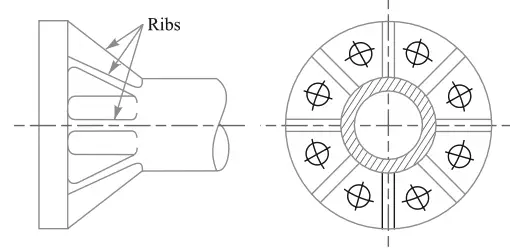

The flanged joint is one of the most widely used pipe joints. In this flanged joint, the flanges are either integral parts of the pipe or sometimes loose flanges are welded or screwed. The following figure shows a Circular Flanged pipe joint with integral flanges on the two pipe ends. The flanges are joined using bolts to form the joint.

- The flanges have seen standardised for pressures upto 2 N/mm2.

- The flange faces need to be machined to ensure correct alignment of the pipes.

- The joint can be leakproof by placing a gasket of soft material, rubber or convass between the flanges.

- The flanges need to be thicker than the pipe walls, to provide enough strength.

- Some cases the pipes may be strengthened for high pressure duty by increasing the thickness of pipe for a short length from the flange, as shown in below figure.

- To accommodate more pressure and large diameter pipe sizes, the flanges can be strengthened by ribs or stiffners as shown in below figure. The ribs or the stiffners are placed between the bolt holes.

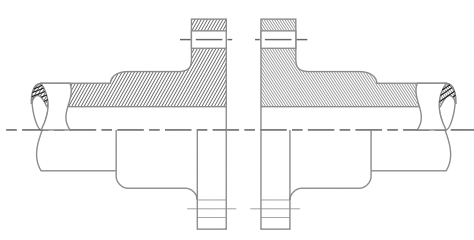

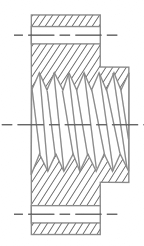

- For larger size pipes, separate loose flanges screwed on the pipes as shown in the below figure are used instead of integral flanges.

Hydraulic pipe joint

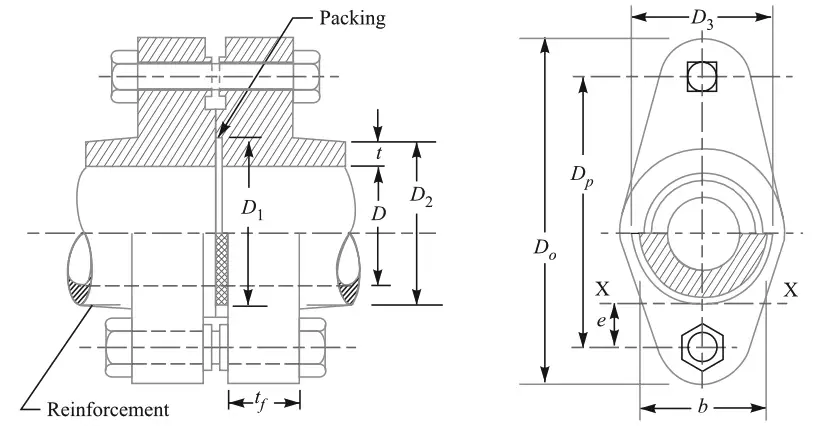

- Hydraulic pipe joint has oval flanges and is fastened using two bolts, as shown in the above figure.

- The oval flanges are usually used for small pipes, up to 175 mm in diameter.

- The flanges are generally cast integral with the pipe ends.

- Such joints are used to carry fluid pressure varying from 5 to 14 N/mm2.

- Such high pressure is found in hydraulic applications like riveting, pressing, lifts etc.

- The hydraulic machines used in these installations are pumps, accumulators, intensifiers etc.

Very important note to use pipe design calculations

- In practice, to design above mentiond joints dimensions are not calculated on a rational basis. The standards are evolved on the basis of long practical experience, suitability and interchangeability.

- Indian Boiler regulation has the autharity to approve the design for boilers, steam generators distributing pipe systems.

- The calculated dimensions for the pipe design as discussed in the previous article do not agree with these standards.

- It is of reader interest only that you should know how to use fundamental principles in determining various dimensions such as wall thickness of pipe, size and number of bolts, flange thickness.

- The rest of the dimensions may be obtained from standard tables or by empirical relations.

Conclusion

We have discussed all the main types of pipe joints such as Socket Joint, Nipple Joint, Union Joint, Spigot & Socket Joint, Expansion Joint, Flanged Joint, and Hydraulic pipe joint. Let us know what do you think about this article in the comment section below.

Leave a Reply