We have already discussed that a V-belt is mostly used in factories and workshops where a great amount of power is to be transmitted from one pulley to another when the two pulleys are very near to each other. Let us discuss more details on the V-Belt Drives and Pulleys.

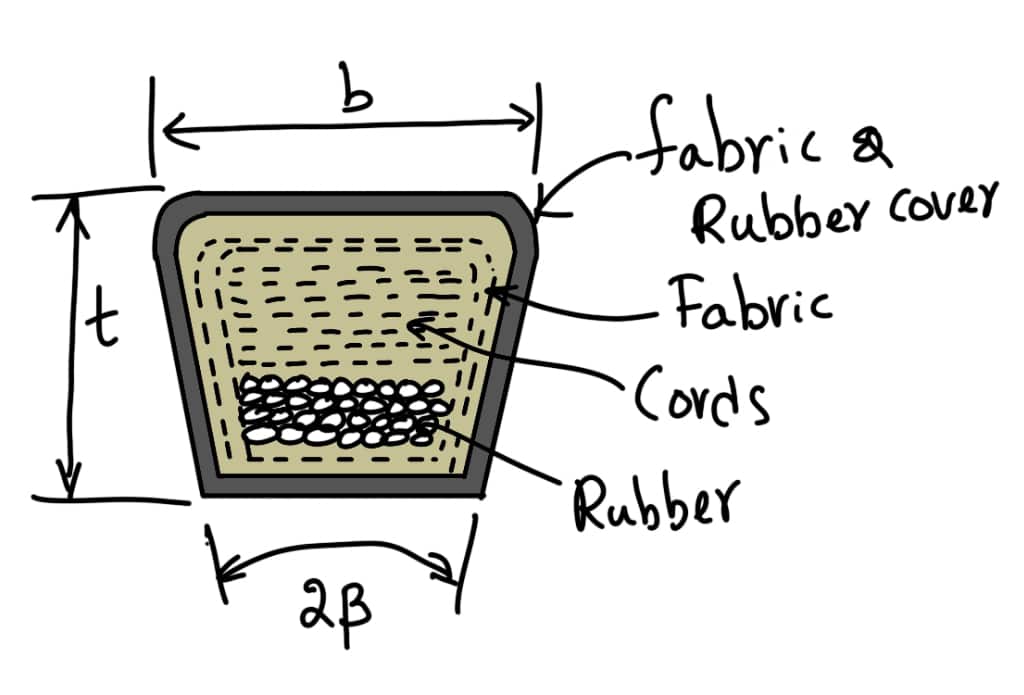

The V-belts are made of fabric and cords molded in rubber and covered with fabric and rubber as shown in the following figure. These belts are molded to a trapezoidal shape and are made endless. These are particularly suitable for short drives. The included angle for the V-belt is usually from 30° to 40°. The power is transmitted by the wedging action between the belt and the V-groove in the pulley or sheave.

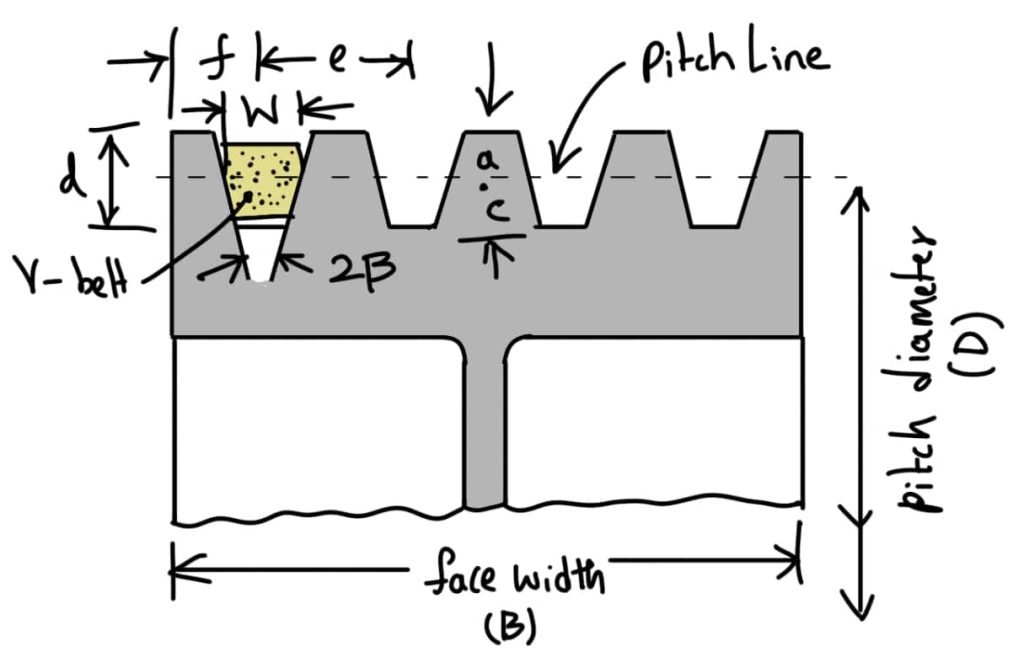

A clearance must be provided at the bottom of the groove as shown in the following figure, to prevent touching of the bottom as it becomes narrower from wear. The V-belt drive may be inclined at any angle with a tight side either at the top or bottom. To increase the power output, several V-belts may be operated side by side. It may be noted that in multiple V-belt drives, all the belts should stretch at the same rate so that the load is equally divided between them.

When one of the set of belts breaks, the entire set should be replaced at the same time. If only one belt is replaced, the new unworn and unstretched belt will be more tightly stretched and will move with different velocities.

Types of V-belts and Pulleys

According to Indian Standards (IS: 2494 – 1974), the V-belts are made in five types i.e. A, B, C, D and E. The dimensions for standard V-belts are shown in the following table.

| Type of belt | Power ranges in kW | Weight per meter length in Newton | Top width (b) mm | Thickness (t) mm | Weight per meter length in Newton |

| A | 0.7 – 3.5 | 75 | 13 | 8 | 1.06 |

| B | 2 – 15 | 125 | 17 | 11 | 1.89 |

| C | 7.5 – 75 | 200 | 22 | 14 | 3.43 |

| D | 20 -150 | 355 | 32 | 19 | 5.69 |

| E | 30 – 350 | 500 | 38 | 23 | – |

The pulleys for V-belts may be made of cast iron or pressed steel in order to reduce weight. The dimensions for the standard V-grooved pulley according to IS: 2494 – 1974, are shown in the following table.

| Type of belt | w | d | a | c | f | e | No. of sheave grooves (n) | Groove angle (2β) in degrees |

| A | 11 | 12 | 3.3 | 8.7 | 10 | 15 | 6 | 32, 34, 38 |

| B | 14 | 15 | 4.2 | 10.7 | 12.5 | 19 | 9 | 32, 34, 38 |

| C | 19 | 20 | 5.7 | 10.8 | 17 | 25.5 | 14 | 34, 36, 38 |

| D | 27 | 28 | 8.1 | 14.3 | 24 | 37 | 14 | 34, 36, 38 |

| E | 32 | 33 | 9.6 | 19.9 | 29 | 44.5 | 20 | – |

Standard Pitch Lengths of V-belts

According to IS: 2494-1974, the V-belts are designated by its type and nominal inside length. For example, a V-belt of type A and inside length 914 mm is designated as A 914–IS: 2494. The standard inside lengths of V-belts in mm are as follows:

610, 660, 711, 787, 813, 889, 914, 965, 991, 1016, 1067, 1092, 1168, 1219, 1295, 1372, 1397, 1422, 1473, 1524, 1600, 1626, 1651, 1727, 1778, 1905, 1981, 2032, 2057, 2159, 2286, 2438, 2464, 2540, 2667, 2845, 3048, 3150, 3251, 3404, 3658, 4013, 4115, 4394, 4572, 4953, 5334, 6045, 6807, 7569, 8331, 9093, 9885, 10617, 12141, 13665, 15189, 16713.

According to IS: 2494-1974, the pitch length is defined as the circumferential length of the belt at the pitch width (i.e. the width at the neutral axis) of the belt. The value of the pitch width remains constant for each type of belt irrespective of the groove angle.

The pitch lengths are obtained by adding to the inside length: 36 mm for type A, 43 mm for type B, 56 mm for type C, 79 mm for type D, and 92 mm for type E. The following table shows the standard pitch lengths for the various types of belts.

| Type of belt | Standard pitch lengths of V-belts in mm |

| A | 645, 696, 747, 823, 848, 925, 950, 1001, 1026, 1051, 1102 1128, 1204, 1255, 1331, 1433, 1458, 1509, 1560, 1636, 1661, 1687, 1763, 1814, 1941, 2017, 2068, 2093, 2195, 2322, 2474, 2703, 2880, 3084, 3287, 3693. |

| B | 932, 1008, 1059, 1110, 1212, 1262, 1339, 1415, 1440, 1466, 1567, 1694, 1770, 1821, 1948, 2024, 2101, 2202, 2329, 2507, 2583, 2710, 2888, 3091, 3294, 3701, 4056, 4158, 4437, 4615, 4996, 5377. |

| C | 1275, 1351, 1453, 1580, 1681, 1783, 1834, 1961, 2088, 2113, 2215, 2342, 2494, 2723, 2901, 3104, 3205, 3307, 3459, 3713, 4069, 4171, 4450, 4628, 5009, 5390, 6101, 6863, 7625, 8387, 9149. |

| D | 3127, 3330, 3736, 4092, 4194, 4473, 4651, 5032, 5413, 6124, 6886, 7648, 8410, 9172, 9934, 10 696, 12 220, 13 744, 15 268, 16 792. |

| E | 5426, 6137, 6899, 7661, 8423, 9185, 9947, 10 709, 12 233, 13 757, 15 283, 16 805. |

The V-belts are also manufactured in non-standard pitch lengths (i.e. in oversize and undersize). The standard pitch length belt is designated by grade number 50. The oversized belts are designated by a grade number more than 50, while the undersized belts are designated by a grade number less than 50. It may be noted that one unit of a grade number represents 2.5 mm in length from the nominal pitch length. For example, a V-belt marked A – 914 – 50 denotes a standard belt of inside length 914 mm and a pitch length 950 mm. A belt marked A – 914 – 52 denotes an oversized belt by an amount of (52 – 50) = 2 units of grade number. Since one unit of grade number represents 2.5 mm, therefore the pitch length of this belt will be 950 + 2 × 2.5 = 955 mm. Similarly, a belt marked A – 914 – 48 denotes an undersized belt, whose pitch length will be 950 – 2 × 2.5 = 945 mm.

Advantages of V-belt Drive over Flat Belt Drive

- The V-belt drive gives compactness due to the small distance between the centers of the pulleys.

- The drive is positive because the slip between the belt and the pulley groove is negligible.

- Since the V-belts are made endlessly and there is no joint trouble, therefore the drive is smooth.

- It provides a longer life, 3 to 5 years.

- It can be easily installed and removed.

- The operation of the belt and pulley is quiet.

- The belts have the ability to cushion the shock when machines are started.

- The high-velocity ratio (maximum 10) may be obtained.

- The wedging action of the belt in the groove gives a high value of limiting *ratio of tensions. Therefore the power transmitted by V-belts is more than flat belts for the same coefficient of friction, arc of contact, and allowable tension in the belts.

- The V-belt may be operated in either direction, with the tight side of the belt at the top or bottom. The center line may be horizontal, vertical, or inclined.

Disadvantages of V-belt Drive over Flat Belt Drive

- The V-belt drive can not be used with large center distances, because of the larger weight per unit length.

- The V-belts are not so durable as flat belts.

- The construction of pulleys for V-belts is more complicated than pulleys of flat belts.

- Since the V-belts are subjected to a certain amount of creep, therefore these are not suitable for constant-speed applications such as synchronous machines and timing devices.

- The belt life is greatly influenced with temperature changes, improper belt tension, and mismatching of belt lengths.

- The centrifugal tension prevents the use of V-belts at speeds below 5 m / s and above 50 m/s.

Ratio of Driving Tensions for V-belt

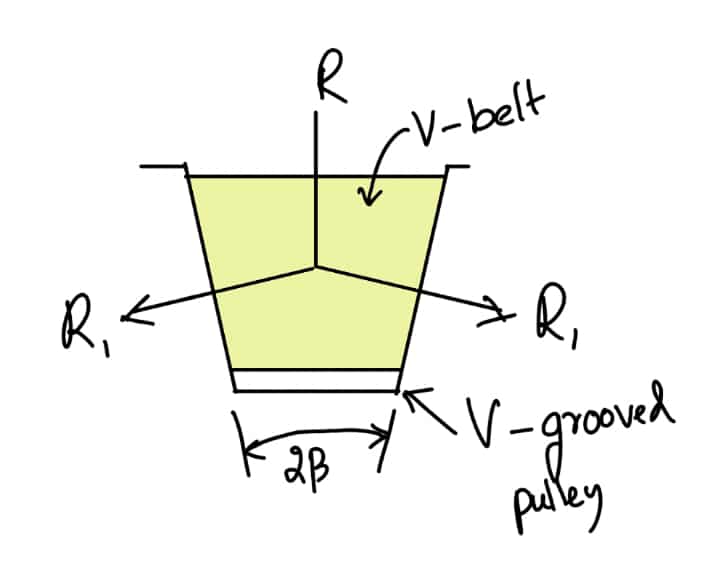

A V-belt with a grooved pulley is shown in the following figure

Let

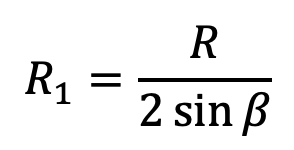

R1 = Normal reactions between belts and sides of the groove.

R = Total reaction in the plane of the groove.

μ = Coefficient of friction between the belt and sides of the groove.

Resolving the reactions vertically to the groove, we have

R = R1 sinβ + R1 sinβ = 2 R1 sinβ

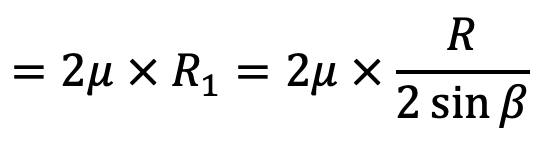

We know that the frictional force

Consider a small portion of the belt, as in Art. 18.19, subtending an angle δθ at the center, the tension on one side will be T and on the other side (T + δT). Now proceeding in the same way as we did in the previous article, we get the frictional resistance equal to μ R. cosec β against μ.R. Thus the relation between T1 and T2 for the V-belt drive will be

2.3 log (T1/T2) = μ θ cosec β

Leave a Reply