A spring is defined as an elastic body, whose function is to distort when loaded and to recover its original shape when the load is removed. It absorbs or controls energy due to either shock or vibration so it can be used as shock absorbers and vibration dampers. It is also used to apply forces, as in brakes, clutches, and spring-loaded valves. We have discussed different types of Springs. We also discussed the Stresses in Helical Springs of circular Wire in the previous article. Let us discuss the different Stresses in Helical Springs of non-circular Wire.

Applications of Springs

The various important applications of springs are as follows:

- To cushion, absorb, or control energy due to either shock or vibration as in car springs, railway buffers, aircraft landing gears, shock absorbers, and vibration dampers.

- To apply forces, as in brakes, clutches, and spring-loaded valves.

- To control motion by maintaining contact between two elements as in cams and followers.

- To measure forces, as in spring balances and engine indicators.

- To store energy, as in watches, toys, etc.

Types of Springs

Though there are many types of springs, the following, according to their shape, are important from the subject point of view.

- Helical springs

- Conical and volute springs

- Torsion springs

- Laminated or leaf springs

- Disc or Belleville springs

- Special-purpose springs

We have discussed more details in a separate article here!

we also discussed the Stresses in Helical Springs of circular Wire in the previous article.

Stresses in Helical Springs of Non-circular Wire & Deflection

In Helical springs, the major type of stress-induced is the torsional shear stress due to twisting. Let us only consider these Stresses in Helical Springs of Circular Wire.

The helical springs may be made of non-circular wire such as rectangular or square wire, to provide greater resilience in a given space. However, these springs have the following main disadvantages:

- The quality of material used for springs is not so good.

- The shape of the wire does not remain square or rectangular while forming helix, resulting in trapezoidal cross-sections. It reduces the energy-absorbing capacity of the spring.

- The stress distribution is not as favorable as for circular wires. But this effect is negligible where loading is static.

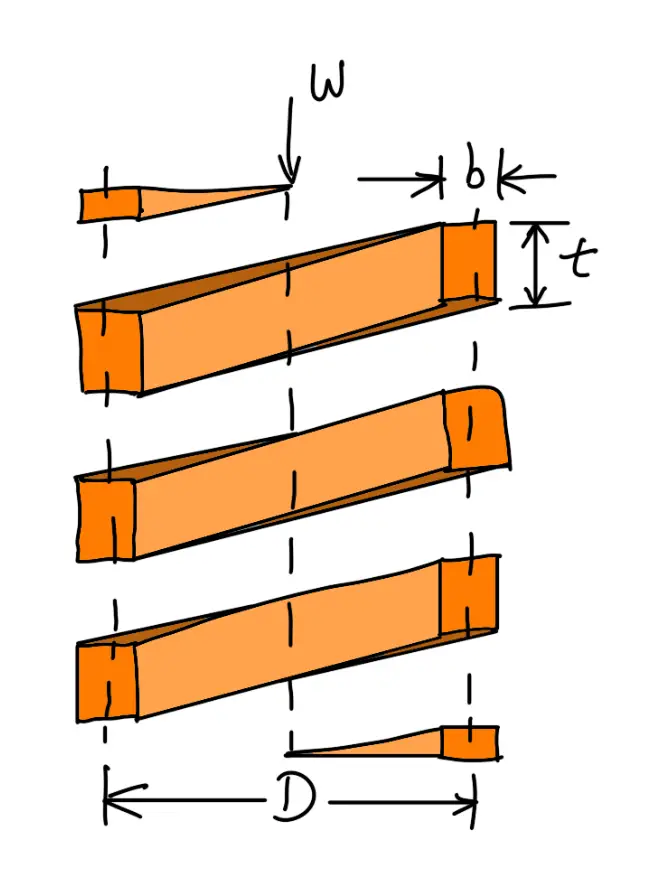

For springs made of rectangular wire, as shown in the following figure,

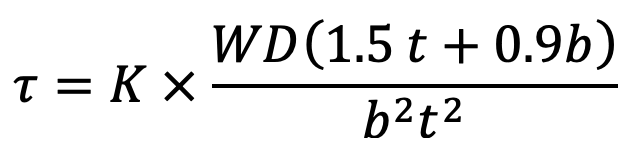

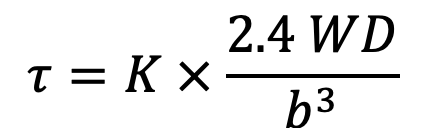

the maximum shear stress is given by

This expression is applicable when the longer side (i.e. t > b) is parallel to the axis of the spring. But when the shorter side (i.e. t < b) is parallel to the axis of the spring, then maximum shear stress,

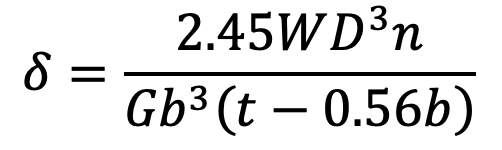

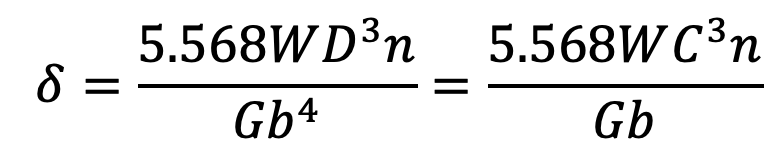

and deflection of the spring,

For springs made of square wire, the dimensions b and t are equal. Therefore, the maximum shear stress is given by

and deflection of the spring,

Where

D = Mean diameter of the spring coil

n = Number of active coils

G = Modulus of rigidity for the spring material

W = Axial load on the spring

τ = Maximum shear stress induced in the wire

C = Spring index = D/d

p = Pitch of the coils

δ = Deflection of the spring, as a result of an axial load W

b = Side of the square

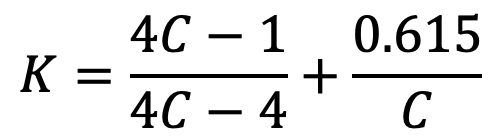

K = Wahl’s stress factor

we know K

This is all about the different Stresses in Helical Springs of Non-circular Wire. Let us know what you think about this article in the comment section below.

Leave a Reply