As we have already discussed what is product design & development and the challenges in the previous article, Now we will look into the different Product Development Processes and understand the significance.

Product Development Processes

The product development processes are the sequence of the activities that a firm or a business enterprise employs to conceive, design, produce and commercialize a product.

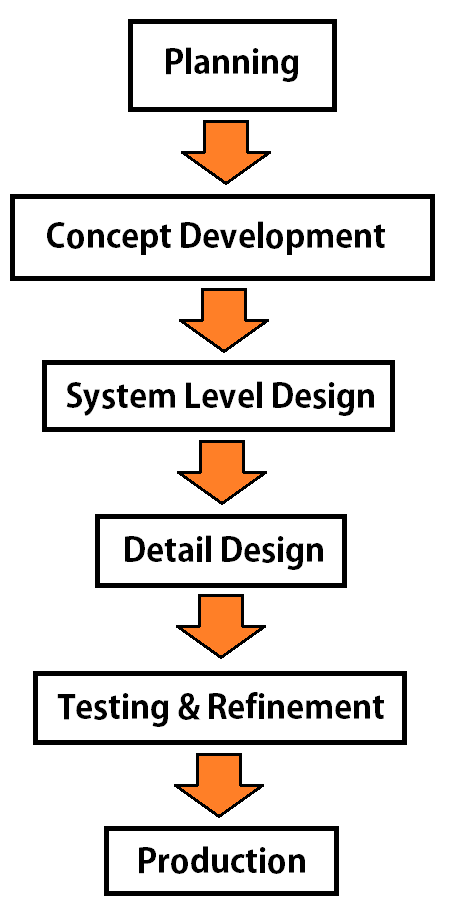

This flow of activities will be followed by organizations to achieve better results. These processes might be different for the different firms, even they follow different processes for the different development projects. But a generic product development process consists of six phases.

- Planning

- Concept Development

- System-Level Design

- Detail Design

- Testing & Refinement

- Production Ramp-up

Planning

This process is often referred to as “Phase Zero”. This process begins with opportunity identification guided by corporate strategy and includes the assessment of technology developments and market objectives. In this process, we will come up with the project mission statement.

What is the project mission statement?

The project mission statement will describe the target for the market for the product business goals, key assumptions, and constraints.

In the planning phase itself, we have to identify the key activities and responsibilities for the different organizations (Design, manufacturing, Marketing, and some other functions).

Concept Development

In the concept development phase, the information about the different alternative product concepts are gathered and evaluated, and concepts are selected for further step. This concept selection included the function, features, specifications and form of the product. During the concept development process and the concept selection, the analysis of the competitive products should be evaluated and the economical justification for this new product development has to be done.

System-Level Design

As we have already selected the product concept and its time to adopt it and proceed with the divide further sublevel systems and the components and preliminary designs of the key components. Along with this preliminary design, a process workflow will be defined which includes the production system and the final assembly. So the final outcome in this phase will be the preliminary design, product function, specification of each subsystem and the process workflow.

Detail Design

As we have the preliminary design of the product, we will proceed with further details of the product such as the specification of the geometry and the materials and tolerances of components, and the identification of the bought-out components from suppliers. A process plan is established and the tooling and is designed for each part to be fabricated within the production system.

The outcome of this phase is controlled documentation of the product design and detail drawings, and CAD files describing the geometry of each and every component in the product, production tooling specifications, and the manufacturing processes involved, specifications of the bought out components, assembly detailing. The main challenges in this phase are material selection, production cost and performance.

Testing & Refinement

As we have the detailed design and drawings we have to make a prototype and need to evaluate whether the product will work according to the described specifications, and does it satisfy the customer needs. This phase is considered alpha testing. In this phase, the prototype production may not be followed by the manufacturing procedures. Later the beta test phase will start, in this phase, the prototype builds in with the intended manufacturing processes as specified in the above phases. But the final assembly will not be followed by the intended processes as mentioned in the above phases. This beta test product will be tested internally and also tested by the few customers.

The main objective of beta testing is to evaluate the performance and reliability in order to identify the necessary engineering changes for the final product.

Production Ramp-up

As we have tested the product and collected the feedback and made the engineering changes and amendments for the product designs and the specifications, now the product is made using the intended production system.

The main objective of ramp-up is to train the workforce and solve any further remained problems in the production process. Thes output productions initially supplied to the specific customer and carefully evaluated for any flaws and solve them further. Going forward this ramp-up will become the ongoing production. During this production transition, the product will be launched and available for all customers and distributors, suppliers.

A postlaunch Project Review will be conducted after the product launch to review and assess the project from both the technical aspects and the commercial aspects to improve the development process for future projects.

Conclusion

We have discussed the different phases in the product development processes. If you have any further thoughts on this topic, let us know in the comment section below.

I loved it when you said that the product development processes are the sequence of the activities that a firm or a business enterprise employs to conceive, design, produce and commercialize a product. My sister is planning of developing a new product for his business. I will tell her to consult a company that specializes in Product Design and Development for better results.

Glad to hear Mr. Jeff Carbine