We have discussed different manufacturing processes, such as Casting, Moulding, Forming, Machining and Joining. Powder metallurgy is also one of the manufacturing techniques to produce precise and highly accurate parts. In Powder metallurgy, the products are produced by pressing powdered metals and alloys into a rigid die under extreme pressure. Let us understand what are the different processes involved in the Powder Metallurgy Process with a neat schematic diagram.

Powder Metallurgy

As we mentioned above the products are produced by Powder metallurgy by pressing powdered metals and alloys into a rigid die under extreme pressure. With the recent technological developments in metallurgy, powder metallurgy has become the essential process for the production of bushings, bearings, gears, and an assortment of structural parts.

In Powder Metallurgy the accuracy and success of powder metallurgy is the sintering process that heats parts and places them under pressure to bond the powder particles. The temperature in sintering is slightly below the melting point of the primary metal such that the bonds of the powdered particles are bound together.

Powder Metallurgy Process

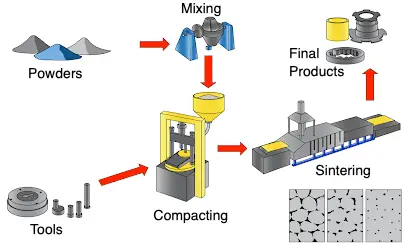

In the powder metallurgy process (PM), fine powders of metals and alloys are compacted together by

pressing the powder in a mould or die to control the shape of the finished product. The pressure used for

compaction is high so that the metal or alloy particles get mechanically interlocked. The part also develops enough strength, so that it may be taken out of the die or mould cavity without damage or

crumbling back to powder form. The product of this compaction process is known as ‘‘green compact’’.

Its strength is low, and its density is below that of corresponding solid metal or alloy. It is also somewhat porous.

To produce a useful strength level, the green compact is sintered at a high temperature but below

the melting point of the powder-metal in a neutral or reducing atmosphere. An exchange of atoms

between individual particles welds them together into a slightly porous piece of metal of the approx.

shape and size of the die or mould cavity.

The sintered component may be used as such or may undergo some secondary operations before being used.

Now let us discuss, in some detail, the various steps involved in making Powder Metallurgy components

- Metal Powder Production

- Blending

- Compacting

- Sintering

- Secondary operations

1. Metal Powder Production

Metal powders can be produced in several ways of which atomisation is the most important. In this process, metal or alloy is heated until it melts. The molten metal is then gravity-fed through a nozzle where it is impinged with a high-velocity stream of water, air or nitrogen atomising it. Upon solidification, the atomised particles of metal or alloys are of various shapes and sizes. These may have to be pulverised to a fine powder of size below 100 microns.

2. Blending

Blending means agitation of powder for homogenizing the particle sizes. While blending some lubricants are also added so that during the next operation of compacting, the die wear and the friction between the metal particles may be reduced. The usual lubricants used are powdered graphite or lithium stearate. Blending is usually done dry—no water is added.

3. Compacting

After blending, the powders are placed in a die and compacted by pushing a punch in under pressure. The dies are usually made of tungsten carbide to reduce the wear of the die. The use of lubricants is necessary to reduce the wear of dies and to reduce compacting force in order that the density of ‘‘green compact’’ is almost as high as the density of the solid metal. Ejection of green compact from the die also becomes easier with the use of lubricants. Compacting requires high pressures of the order of 700 MPa to cause mechanical interlocking in particles. Before sintering, however, the lubricant must be driven out by a low-temperature heating cycle.

4. Sintering

This is the next step in the Powder Metallurgy process. The green compacts are heated in a muffle type furnace in a controlled atmosphere. For ferrous metals, a dissociated ammonia atmosphere is used to control carburization or decarburization of the powder compact. Temperatures are maintained between 60–80% of the melting point of metal or alloy concerned. Sintering time may range from 20 minutes to 60 minutes. Sintering raises the ultimate strength of the product. It results in the diffusion bonding of particles.

5. Secondary operations

Many Powder Metallurgy parts are used in as-sintered conditions. Others may require some secondary operations like an infiltration, sizing, coining, impregnation or heat treatment before use.

- The object of infiltration is to increase strength, density and hardness. It is done by placing a slug of copper alloy on top of Powder Metallurgy parts during the sintering process. Copper alloy melts and infiltrates the small pores in the Powder Metallurgy part by capillary action.

- In sizing and coining operations, the sintered part is repressed in the die to increase its strength and density by cold working. In addition, the tolerance on the size becomes closer and the size of the part becomes more accurate.

- In impregnation, the sintered parts (if required) are impregnated with grease or oil by heating them to about 100°C in oil etc. for 10–15 minutes. Such oil or grease impregnated parts provide self-lubricating properties.

- Powder Metallurgy parts can also be heat treated like wrought or cast metal parts to improve their grain structure, strength and hardness.

Advantages of Powder Metallurgy Process

- The main advantage of the Powder Metallurgy process is that accurate control over powder can be exercised permitting variation in physical and mechanical properties.

- If so desired a part can be made with different densities in different portions of the same part.

- Parts can be made in different shapes accurately so that no subsequent machining is required.

- Small gears and parts with spline or irregular shapes can be produced cheaply and accurately.

- The Powder Metallurgy process is metal and energy-efficient.

- Powder Metallurgy parts are also relatively free from defects.

- The main disadvantage is that initial tooling costs are high and it cannot produce parts with weak thin sections.

Conclusion

In engineering, in very special cases where a conventional manufacturing method is not applicable to produce the required component, we use the Powder Metallurgy Process. Mostly this process is used in the production of unique metals like Tungsten Carbide. We have discussed how this process can be performed step by step with the neat schematic diagram and also given some of the advantages. Let us know what do you think about this article in the comment section below.

Very excellent articles and good information