In the previous article, we have discussed the different types of manufacturing processes for engineering materials. Engineering materials are referred to as non-metallic, metallic materials, ceramics and composites. In this article, we will discuss the Different Manufacturing Processes for Plastic Products (Non-metallic products).

Non-Metal is referred to the chemical elements which are volatile, insulated to heat and electricity and lack metallic attributes. Most of the non-metals are gasses. In the periodic table, they are represented under Polyatomic non-metal, Diatomic non-metal, and Noble gases. carbon, phosphorus, sulfur, selenium, and iodine are the solid non-metals.

Please read the full article on the Non-metallic materials here

Non-metals are further classified into the following groups.

- Thermoplastics

- Thermosets or Thermosetting plastics

- Elastomers

Manufacturing Processes for Plastic Products

Now, let us discuss the different Nonmetallic manufacturing processes for plastic products irrespective of the above classification. We will describe three common methods. These are

- Injection moulding

- Extrusion

- Blow moulding

1. Injection Moulding

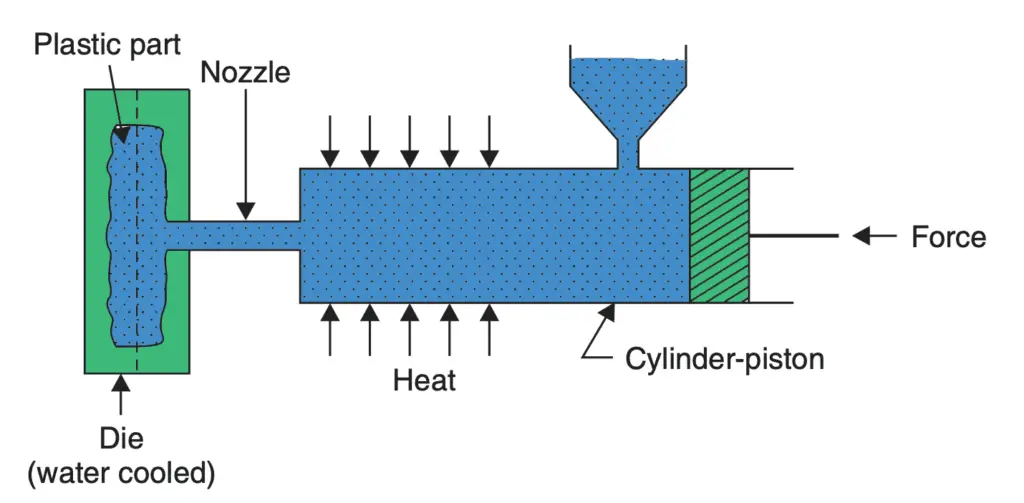

This is the method used for large scale production of thermoplastic components. The plastic powder is filled into a hopper connected to a cylinder-piston mechanism. As the piston withdraws, some plastic powder is inducted into the cylinder and the piston then moves it forward by exerting pressure on it. The cylinder is heated so that the plastic powder gets heated to a temperature between 175–275°C. Under the action of heat and pressure, the plastic softens and is forced through a nozzle into a water-cooled die. this is shown in the following figure.

After the plastic part has cooled and solidified, it is ejected out of the die and the cycle starts all over again.

2. Extrusion

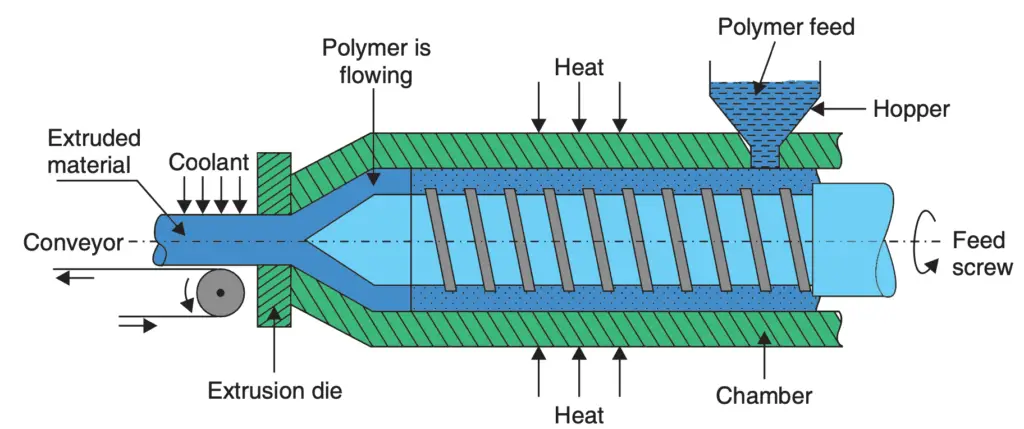

This process is also called extrusion moulding. This method is also suitable for thermoplastics, thermosetting plastics are generally not suitable for extrusion. By extrusion, solid rods, pipes, tubing and different sections can be made. The scheme of the extrusion process is shown in the following figure.

A hopper feeds polymer material into a chamber, which is kept heated. A screw rotates in the centre of this chamber feeding the polymer material forward. Under the action of heat and pressure, it starts flowing. In the front portion of the chamber, a (heated) die is fitted, which provides the only exit for the material. As more and more material is screw fed, a continuous stream of material is squeezed out from the die, its cross-section acquiring the shape of the die. The material coming out of the die is cooled and carried off by a suitable belt conveyer.

3. Blow Moulding

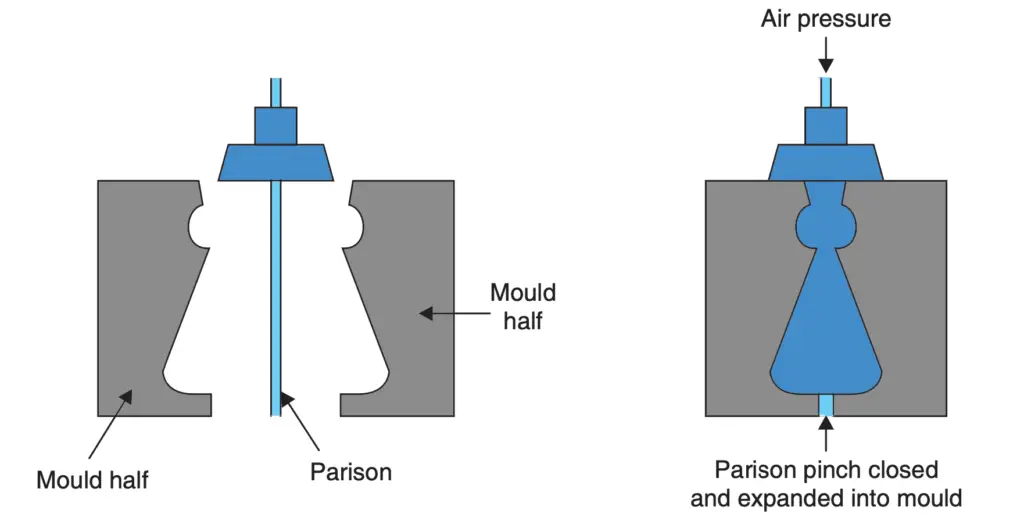

This process has been used for making plastic bottles, toys, hollow dolls and similar other items. The blow moulding begins with a heated tubular piece of plastic, which is called PARISON. The parison is positioned in between a two-piece mould as shown in the following figure.

The bottom opening of the parison gets pinch closed and sealed as the two-piece mould closes. Air is then injected into the parison under pressure (0.7–10 kg/cm2) thereby forcing the plastic to acquire the shape of the mould. The mould is opened and the part formed inside the mould is removed after it has cooled sufficiently.

The above process is similar to making articles of glass by blowing air into a mass of molten glass.

These are the different Manufacturing Processes for Plastic Products. Let us know what do you think about this article in the comment section below.

Leave a Reply