Casting is a manufacturing process used in foundries to produce metal components from Ferrous and Non-ferrous metals. Casting is one of the most important manufacturing processes among all processes. The casting process is pouring molten metal into the moulds. We have discussed how moulds are prepared with sand and Die-casting moulds. But how the Molten Metal is prepared in Cupola Furnace to pour into the Mould in detail.

Different Types of Furnaces

As you already know that the casting process is pouring molten metal into the moulds. To prepare this molten metal for casting, metal has to be heated above its melting point. The heating is done in a furnace. Depending upon the fuel used, the furnaces may be classified into many types. Let us consider the most common 3 types of furnaces.

- Electric Furnace

- Oil-fired Furnace

- Coal-fired Furnace

Where the molten metal should be free from any impurities is required, then we use the electric furnaces. Usually, these Electric furnaces are costly and equally costly to operate.

In oil-fired and coal-fired furnaces, the flame plays upon the hot metal and the molten metal picks up impurities by coming in contact with flames.

Usually, for non-ferrous metals and alloys, oil fired crucible furnaces are used. The metal is placed in large graphite crucibles and heated on the outside surface of crucibles so that flames do not come in actual contact with the metal.

For melting cast iron, a cupola furnace is used. Let us discuss the construction and operation of this Cupola Furnance.

Cupola means A round dome shape on top.

Cupola Furnace Construction

- Cupola Furnace is one of the most economical and convenient ways of providing a supply of molten cast iron for the Casting Process.

- Cupola uses coke as fuel. Coke is produced by heating ordinary steam coal in an inert atmosphere.

- It gives more intense heat than coal.

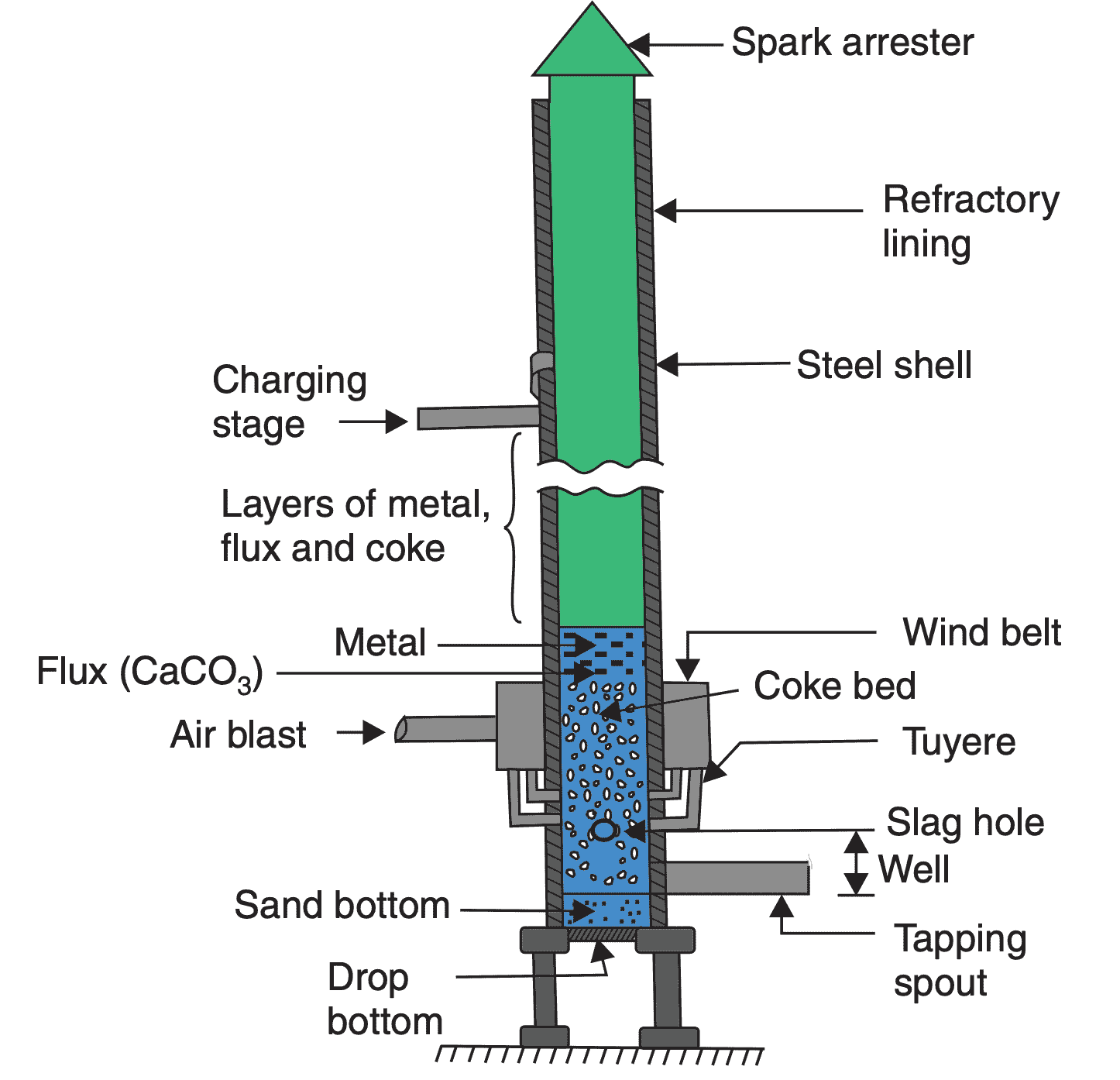

- Cupola consists of a long cylindrical steel shell with its interior lined with refractory fire bricks.

- It is erected vertically up and rests on short pillars about 0.85 metres above ground level.

- The bottom of the cupola is provided with steel doors which are also lined with fire-resistant material and covered with a layer of good quality sand.

- At a suitable height, near the top of this steel shell, an opening is cut, which is used for charging fuel and raw materials into the furnace.

- A wind box, connected to a motorised blower is provided at a height of one meter or so above the bottom closing doors.

- From this wind box, small air passages are provided into the cupola shell for the supply of air to aid the combustion of fuel.

- These air passages are called tuyeres.

- At the bottom, above the door, a tapping spout is provided.

- The Tapping Spout is to tap molten metal and about 350 mm above the tapping hole another hole called the slag hole is provided at the back of the cupola.

- Through this slag hole, liquid slag can be forced out under air pressure.

- The cylindrical space provided between the tap hole and the slag hole is called the molten metal well in which the molten metal accumulates between two taps.

Operation Of Cupola Furnace

- In the cupola, the first operation is to repair the lining of the door and the area around it and then close the hinged doors.

- Doors are jammed shut so that there is no possibility of their opening while the cupola is in operation.

- Then the fire is lighted at the bottom with the help of some wood and kerosene oil rags.

- When the fire is burning strongly, coke is added from the top charging door until the height of the coke bed reaches about half a metre above tuyeres.

- After that tuyeres are opened partially, the air blower is switched on and alternate layers of metal, flux (in the form of limestone pieces) and coke are charged from the top.

- These alternate layers settle down on the coke bed.

- When the cupola is filled up to the level of the charging door, the tuyeres are opened fully and the heating of the charge begins.

- The coke near the tuyeres starts burning and the coke bed becomes intensely hot.

- The metal in the lower layers near the coke bed starts melting.

- Limestone breaks down to CaO and CO2.

- The calcium oxide reacts with impurities like silica and other oxides forming slag (CaSiO3 ).

- Slag is lighter and floats upon the molten metal layer.

- Ultimately, when enough metal has melted, the slag is blown out by opening the slag hole.

- The metal is then tapped by puncturing the tap hole with a long steel rod with one end shaped like a cone.

- The molten metal will start flowing into the metal chute and is collected into ladles (refractory-lined steel buckets to which long handles are welded) and taken away for pouring into moulds.

- The tap hole is then closed by plugging it with a lump of fire clay.

- The properties of cast iron improve with the addition of small amounts of ferromanganese and ferrosilicon.

- Since most of the manganese and silicon are already present in scrap cast iron, pig iron and a little bit of thin steel scrap, which forms the metallic charge dropped into the cupola, is oxidised and lost, the addition of ferromanganese and ferrosilicon has to be done to the molten metal in the ladles before pouring.

- After the day’s work is over, extra coke is charged into the cupola along with the last charge.

- After all the metal has melted, the air blower is switched off and the bottom door of the cupola is opened.

- Whatever unburnt coke etc., is left, is allowed to fall to the ground beneath the cupola door.

- This is necessary otherwise the leftover coke, slag and metal etc. may join up in one mass, then its removal will become extremely difficult.

- The size of a cupola is denoted by its internal diameter.

This is how Cupola Furnace works.

Conclusion

Cupola Furnace is one of the most economical and convenient ways of providing a supply of molten cast iron for the Casting Process. We have discussed the construction and the operation of the Cupola Furnaces. Let us know in the comment section what are the advantages and disadvantages you know about the Cupola Furnace.

Leave a Reply