We have been discussed the different types of the Internal combustion Engines, and their working principles, In this article we are going to discuss the different Engine Performance Parameters.

The Overall Engine performance is indicated by the term ” Efficiency” and denoted by “η”

There are five important Engine efficiencies which are mentioned below.

- Indicated Thermal Efficiency

- Brake Thermal Efficiency

- Mechanical Efficiency

- Volumetric Efficiency

- Relative Efficiency

These are the five important Engine efficiencies which determine the overall Efficiency of the Engine. Along with these efficiencies, we do have other performance parameters also. Those are listed below.

Engine Performance Parameters

- Mean Effective Pressure

- Mean Piston Speed

- Specific Power Output

- Specific Fuel Consumption

- Air-Fuel Ratio

- Calorific Value of the Fuel

Let’s discuss all these parameters in detail, starting with the Efficiencies.

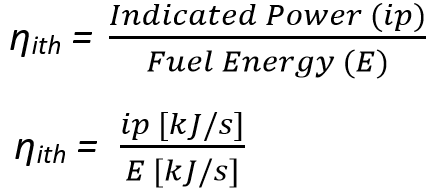

Indicated Thermal Efficiency

Before going to discuss what is Indicated Thermal Efficiency, we have to understand what is Indicated power? and What is the Fuel Energy?

Indicated Power: The amount of power developed by the combustion of the fuel in the cylinder.

Fuel Energy: The actual amount of energy stored in the Fuel = Mass of the fuel × Calorific value of the Fuel

Now with these to the definition for the Indicated Thermal efficiency is clear. The ratio between the Indicated power to the Fuel Energy is called Indicated Thermal Efficiency.

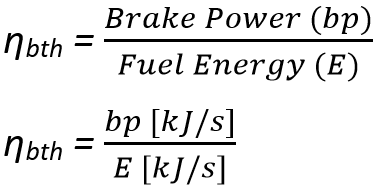

Brake Thermal Efficiency

Before going to discuss what is Break thermal efficiency, we have to understand what is Brake power? and we already know what is Fuel Energy?

Brake Power: The amount of power output collected a the crankshaft is called Brake power.

Now the definition is simple. The ratio between the Brake power to the Fuel Energy is called brake Thermal Efficiency.

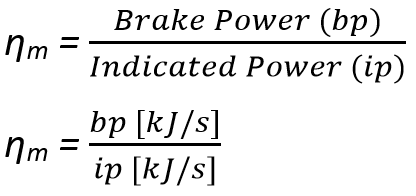

You know, we also have a relation between the Indicated power and the Brake power. It goes like the following.

Indicated Power = Brake Power + Friction Power

[ As the amount of energy developed in the cylinder which is the indicated power cannot be converted into the output (Rotational movement) with 100% energy transfer, there will be friction loss with the piston in the cylinder. so the Output power at the crankshaft is termed as the Brake power and the amount which is lost as the friction loss considered as the friction power.]

Mechanical Efficiency

The mechanical Efficiency is defined as the ratio of the power output to the power developed in the cylinder. Or simply ratio of the Brake power to the indicated Power.

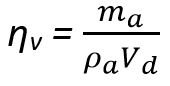

Volumetric Efficiency

Have you heard the term “Breathing ability of the engine” anywhere?

Yes, you have heard correct volumetric efficiency is nothing but the Breathing ability of the engine. And this is one of the important performance parameters for the Four stroke engines.

Volumetric Efficiency is defined as the amount of air intake to the rate at which the volume is displaced by the system.

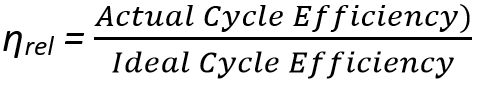

Relative Efficiency

Relative Efficiency is also known as the Efficiency Ratio. This is the ratio of the thermal efficiency of the Actual Cycle and the Ideal Cycle.

Now let’s discuss the remaining Engine Performance parameters.

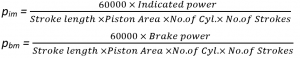

Mean Effective Pressure (pm)

The average pressure inside the cylinders of the internal combustion engine based on the resulted power output.

For any engines, there will be two Mean effective pressures. One is Specific Indicated Mean Effective Pressure(pim), and the Second one is the Brake mean effective pressure (pbm). These two are derived from the indicated power and the brake power.

Mean Piston Speed

Mean Piston speed can be calculated from the following formula

Mean piston speed (Sp) = 2 × Stroke Length × Speed in RPM

Specific Power Output (Sp)

The specific Power output can be simply defined as the power output per unit area of the piston.

Specific Power output (Ps) = Brake Power/Piston Area

(Or)

Specific Power output (Ps) = Brake Mean effective pressure× Mean piston speed × Constant

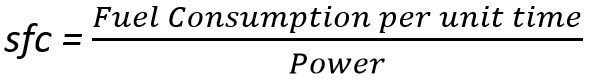

Specific Fuel Consumption

Specific Fuel consumption is an important parameter in terms of determining the performance of the Engine. It is defined as the ratio of the fuel consumed per unit time to the power output generated.

Here also the indicated Specific fuel consumption and the Brake Specific fuel consumption can be calculated from the Indicated power and the Brake power.

Air-Fuel Ratio

The proportions of the air with the fuel play a crucial role in the performance of the engine. This is expressed in the terms of air-fuel ratio. In spark Ignition Engines, the Air-Fuel ratio will be the same for most of the operations. But in the Compression engines where the fuel is entered separately with the help of the fuel injectors, so that if the load need to be increased, then the fuel amount will be increased directly in the cylinder.

Calorific Value (CV) of the Fuel

The calorific value of the fuel is defined as the amount of thermal energy released per unit quantity of fuel when it is burned completely.

Conclusion

We have discussed the different types of Efficiencies in the Internal Combustion Engine, and also the Engine Performance parameters such as the Mean Effective Pressure, Mean Piston Speed, Specific Power Output, Specific Fuel Consumption, Air-Fuel Ratio, Calorific Value of the Fuel. If you have any thoughts please let us know in the below comment section.

In mean effective pressure formula it’s 60000 not 6 thousand