A shaft coupling is a mechanical element that connects the two shafts together to transmit the torque from one end to the other by accommodating the misalignment.

Usually of a shaft can be made up of limited lengths so we have to make a couple multiple pieces of shafts to achieve the larger lengths to transmit the power. The mechanical element used to couple these shafts is called the Coupling.

Purpose of Shaft Coupling

- Connects the driver and driven equipment such as engine and generator.

- To accommodate the misalignment between the two shafts.

- Protection against the shock loads.

- Reduce the transmission of shock loads from one shaft to the other.

What makes a good shaft coupling?

- The coupling should be easy to connect and disconnect.

- Able to transmit full power from one end to the other end.

- Should not transmit the vibrations from one shaft end to the other shaft.

- It should not have any projecting parts.

What are the different types of couplings?

1. Rigid couplings

Rigid Couplings are used to connect two shafts which are perfectly aligned. Following are the different types of rigid couplings.

- Sleeve coupling

- Muff coupling

- Splined coupling

- Clamp or split-muff or compression coupling

- Flange coupling

Read more details about these Rigid couplings here!

2. Flexible coupling

Flexible couplings are used to connect two shafts having axial, radial and angular misalignment. Following are the different types of flexible couplings.

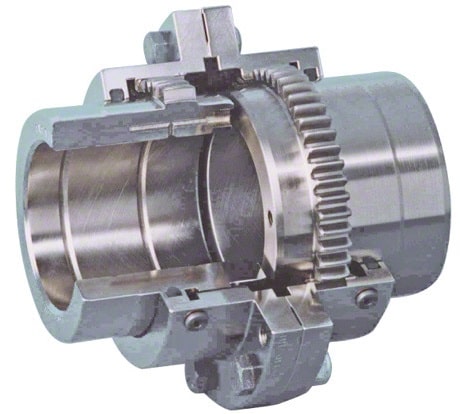

- Gear coupling

- Disc Coupling

- Grid Couplings

- Diaphragm coupling

- Fluid Couplings

- Torsional couplings

- Bushed pin type coupling

- Universal coupling

- Old-ham coupling

These are the list of rigid and flexible couplings. We have discussed each coupling types individually in the other articles. Follow the links.

Flexible Couplings, Rigid Couplings

Conclusion

We have discussed the purpose of the coupling and the functional requirements of a good shaft coupling with the different rigid and flexible couplings types. If you have any further thoughts on this topic, let us know in the comment section below.

You may need to give it a tiny push if it does not start on its own. If you find the correct position of the electromagnet and the magnets on the rotor sides are centered, it should start revolving without the push if your battery is new. Thank you so much!

With the various rigid and flexible coupling types, they have explored the purpose of the coupling and the functional requirements of a suitable shaft coupling. Thank you so much for this wonderful article.

You are welcome!