Carter Carburetor is an automobile Carburetor used mostly in jeeps. In the previous article, we have discussed the other type of automobile Carburetor called Solex Carburetor. In this article, we are going to discuss the Carter Carburetor construction and the working principle.

Carter Carburetor

It was first founded by William Carter for the jeeps run by four-cylinder engines.

Carter Carburetor is a downdraught type Carburetor. It is having multiple jets, a plain tube with only one adjustment for the idling or low speed running of the engine.

Carter Carburetor Construction

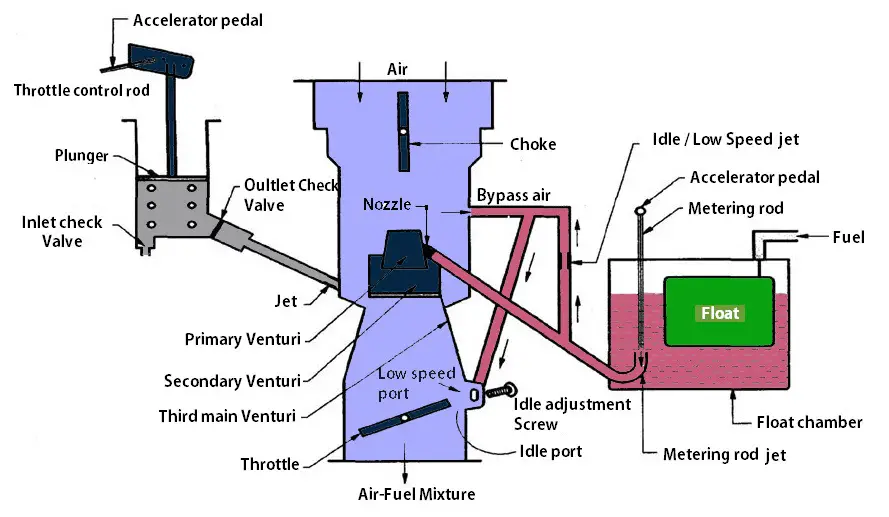

A float with a tapered valve at the top face of the float is arranged in the float chamber to take care of the fuel level in it.

Carter Carburetor

The air enters at the top of the tube operated by the choke valve. During normal operation, the choke valve will be fully opened. This Carburetor is comprised of 3 venturi tubes. Among these, the smallest one is maintained a little bit above to the level of fuel in the float chamber. The other two will be below the level of the fuel in the float chamber.

The fuel nozzle injects the fuel at the primary venturi and throws the fuel against the air flow coming from the top. The air and the fuel mixed at the primary venturi and flow thru the secondary venturi and exposed to some more air steam and further flow thru the third venturi as well. After this, the fuel mixture enters into the engine during the

There is a metering rod provided at the float chamber, which controls the quantity of fuel supply to the engine.

Engine starting circuit

During the engine starting a richer mixture need to be provided. The suction created by the piston during the engine starting is exerted on to the nozzle to provide the correct quantity of the fuel. The choke valve also provides less air. So that correct quantity of the richer mixture is prepared and inducted into the engine cylinder to start the engine smoothly.

After the engine starts, the spring controlled choke valve is open to allow the correct quantity of the air during the period of warm up.

Idle and Low-speed(Cruising) circuit

For the idle speed, the richer mixture is required in small quantity. In this operating condition, the throttle valve is slightly open. So that the suction created by the piston downward movement is exerted on to the ideal port. This is how the rich mixture is provided by the idle/slow speed jet. The air-fuel ratio can be controlled by the idle adjustment screw.

For the low-speed operation, the throttle can be further open to run the engine smoothly above the idle speed operation.

Acceleration of Engine

There is an acceleration pump arrangement as shown in the above diagram. This will helps to accelerate the engine by supplying the additional amount of fuel with the help of jet at the direct throat.

This acceleration pump consists of non-return inlet check valve and the outlet check valve, plunger and a spring operated accelerator pedal. When we push the accelerator pedal, this will push a small amount of petrol to the throat by means of non-return inlet check valve to the

Conclusion

We have discussed the different operating conditions of the engine run by the Carter Carburetors. And also discussed the different functions such as the Normal operating, Idling, Slow running, and acceleration. Let us know your thoughts in the comment section below.

Leave a Reply