A final year project on “AN ASSESSMENT ON THE USE OF GEOSYNTHETIC MATERIALS BY CONSTRUCTION INDUSTRY STAKEHOLDERS IN LAGOS STATE NIGERIA“ submitted by ADEBANJO OLUWATOBI ADEWUMI to extrudesign.com.

ABSTRACT

This study was conducted to assess the level of use of geosynthetic materials by construction stakeholders in Lagos-island and the determining factors responsible for the choice and selection of these materials for construction purposes. Previous studies conducted have shown that the use of geosynthetic materials is increasing daily in India. Also, studies reveal that there is a considerable strength a soil will attain when reinforced with geotextiles and related products. Likewise, previous research showed that natural fibre is considerably good for its eco-compatibility attributes. Therefore, as a result of the research gap in the level of use of geosynthetic materials, this study made use of purposive stratified sampling for data collection from respondents who are the stakeholders in Lagos-island Construction industry. The data used for this study was gathered through a structured questionnaire from the respondents and the data was analyzed using frequency, percentage, mean score and relative importance index which are descriptive and Spearman correlation inferential statistics respectively to achieve the research objectives. The findings revealed that the most known geosynthetic material is geotextile (with a mean score value of 4.3 and RII of 0.91) and followed by geomembranes (with a mean score value of 3.95 and RII of 0.0.83). Also, the most used geosynthetic material is the geotextile (with a mean score value of 3.71 and RII of 0.74) and geomembranes (with a mean score value of 3.34 and RII of 0.67). It was gathered that the most influencing factor on the choice and usage of geosynthetic material is High Strength (with a mean score value of 4.53 and RII of 0.91) followed by Quality assurance and control (with a mean score value of 4.47 and RII of 0.0.85) and Biodegradability (with a mean score value of 4.42 and RII of 0.88) which makes it to have a long life span. The study further identified the major factor affecting the usage to be Effect of weather (with a mean score value of 4.74 and RII of 0.95), followed by User’s choice (with a mean score value of 4.63 and RII of 0.93) and cost as the third affecting factor (with a mean score value of 4.61 and RII of 0.92). This study showed that there is no existing relationship (there is no significant correlation) among the stakeholders in the choice of geosynthetic usage. This research concludes that professionals are moderately aware of geosynthetic materials as a result of their construction experiences and the major factor affecting the use is the weather condition of the environment and lack of relationship among the stakeholders.

Topics: Geosynthetic materials, Construction industry, Construction materials, Civil Engineering,

1. INTRODUCTION

1.1 Background to the Study

The Construction Industry comprises of various firms and companies that are saddled with the responsibilities of building construction, infrastructural development and all civil engineering works. In view of this, the Industry has unique capabilities on infrastructural development, new construction works, repairs, maintenance works and any form of demolition works (Danny,2004). Myers (2013) opined that the Construction Industry is a big and multifaceted industry, housing many members of professionals and contributing significantly to the nations’ economic growth. In light of her contribution, it has an imperative attribute of adding to the Gross Domestic Product of the nation thereby, increasing the economic potentials of the nation. As argued by Olanrewaju and Abdul-Aziz (2015), the Construction Industry has alluded for the stimulation of economic development, Infrastructure development and prosperity. In relation to the economical developmental attributes of the industry, it has the ability to provide for all other sectors in the country and this gives it the potential to create wealth and prosperity. Organization for Economic Co-operation and Development [OECD] (2008), remarked that the Construction Industry majorly acts as a provider of buildings, building materials and Infrastructures on which nearly all other sectors in the country depends.

Furthermore, the production of building materials is a sub-sector under the umbrella of the Construction Industry which helps to see to the manufacture of locally made materials for construction and infrastructural development purposes. Building Construction materials is as old as man and can be dated back to the Stone Age where stone, clay and timber were used as construction materials before the advent of concrete and steel.

Oladiran (2005), put forward that locally made building materials are being referred to as the building materials sourced for locally or manufactured with home-made raw materials, Scholars argued that there is no single definition for the word local materials and on this note, locally made building materials are those materials gotten indigenously within the country which does not involve any form of importation. Example of building materials produced locally in Nigeria includes; Dangote Portland cement, sandcrete block, ceiling asbestos, etc, expressing further, research has paved the way to some other local materials such as ceiling board made from the paper pulp (although not fully patronized).

Omole (2013). stressed that the term “local” when applicative in usage with building materials is in the relative term. He opined that goods or any building materials produced in China, Chicago or Nigeria are all local goods at home in the respective countries. But becomes an imported good to other countries that import those goods and products.

Adedeji (2005) put forward that Nigeria is blessed with quite a number of local materials which can be sourced locally in the country for construction works. Stressing further that with the use of locally made materials developed from either plants or animals can be used rather than the importation of materials from foreign countries. On this note, Morthur (2006) opined that India as an example, makes use of her local resources available to her and this gives light to numerous new products which can be gotten from plants such as Geotextiles with the use of sisal and jute fibres. And that these locally made materials are not well utilized in Nigeria as expected. In view of this, the available raw materials in Nigeria have to be exploited to achieve something new with international standard organization recognition. These are seen as products that can help to build up the Gross Domestic Products for the nation’s economy. In light of the encouragement needed for the implementation of raw materials to produce new products, Windapo and Iyagba (2007) affirm that the major challenge being faced with the production of local building materials is the constant availability of the required raw materials-As a result of non-availability of raw materials for production of local materials, many house producers have resorted to the use of imported materials rather than the use of the locally produced ones all because of non-sustainability, availability and durability of the locally made materials. In light of these challenges, the construction industry has built up the prospect for the use of imported materials for sustainable and durable construction. The geosynthetic materials are imported from various countries into Nigeria so as to possess available construction materials at her doorstep. In lieu of this, Olele (2016) opined that there is an increase in the economic activities around Lekki and its environs. With a soil having low bearing capacities, it becomes a necessity to reinforce the soil using available stabilization technique.

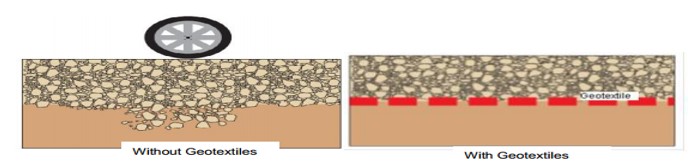

Rudramurthy and Vikram (2016) stress that the use of Geosynthetic material (geotextile) as reinforcement for soils in order to improve its bearing capacities has become successful. With the record of success in the use of Geotextiles to reinforce soil gives confidence that Geotechnical Engineers in lieu of an increase in the bearing ratio of reinforced granular soils with geotextile. He further stresses that an effective means of soil improvement has been achieved with the use of geotextile material in engineering applications.

1.2 Statement of the Research Problem

Oladiran (2015) opined that one major way to bring down the cost of materials for affordable housing is a shift towards the usage of local materials in the country. An increase in the cost of procuring construction materials will lead to an increase in the cost of constructing/developing housing estates. The price of construction materials is greatly influenced by the importation of construction materials for construction purposes.

On this note, Aribigbola (2011) reports that affordable housing is described as the one where the occupants spend 30% or below of their annual income and spend than 20% annual income in Nigeria based on stipulated housing policy.

Additionally, (Windapo & Iyagba. 20()7) opined that there is a strong relationship between housing construction cost and the building material price, property price, money supply, national disposable incon1e, labour cost and exchange rates. Therefore, building materials are therefore one of the major predictors of the future cost of housing and infrastructures in Nigeria. A shift to the usage and application of construction local materials will adequately result in a possible reduction in construction cost in Nigeria and will finally promote affordability of housing estates and development.

Ghosh (2009) discussed that man-made geotextiles of petrochemical constituents have a challenging eco-compatibility. She identified that locally made geotextiles from plant fibres possess eco-friendliness with the environment with the users. With the light of this eco-friendliness, it was discovered that there are problems associated with the use of this material. She discovered that either slowly or quickly, there is a certainty that the natural geotextile will deplete or wear off over time and this quality makes it eco-friendly. ‘This depletion over time is a big challenge to engineers and this has controlled the use of geotextile material in some of the various ways of engineering applications.

According to Rudramurthy and Vikram, (201 6), there is a sure increase in the CBR values of soil that is reinforced with geotextiles. They in their papers carried out an experiment on the bearing ratio capacity of selected soils and the effect of geotextiles as reinforcement to the soil. It was discovered that there is a sure increase in the bearing values of the selected soils and this paved a way for the use of geotextile materials as reinforcement to soil and embankment.

Geosynthetic Institute (GSI, 2015) published that “the national and global status of geosynthetics-aware of graduating engineers, as well as new employees entering into geosynthetics design and consulting organizations, is presently not only weak but shows no promise of improving” The institute stresses that all graduating members of civil engineering and all new employees have a little knowledge of the plethora of available geosynthetic materials including the various applications they serve. It was discovered that the field of engineering is graduating numbers of student yearly both at the undergraduate level and postgraduate level without the knowledge of geosynthetic materials and its various ways of application.

However, several publications have been published on geosynthetics including geotextiles as well discussing their physical and mechanical properties, the effect of geotextile on CBR values, and the need for natural geosynthetics but there has not been a publication on assessment on the use of geosynthetics (geotextiles) by construction stakeholders. Hence, there is a need for an assessment on the use of geosynthetic materials by construction stakeholders in the Nigerian construction industry taking Lagos state as a case study.

1.3 Research Questions

This research will affirmatively proffer answers to the following research questions with respect to the use of geosynthetic materials in Lagos State Nigeria.

- What is the level of use of Geosynthetic materials by construction stakeholders in Lagos state?

- What are the factors influencing the use of Geosynthetic materials by stakeholders in Lagos state?

- What the factors affecting the use of Geosynthetic materials by stakeholders in Lagos state?

- What is the relationship between contractors, consultant and clients in the use of Geosynthetic materials in Lagos State Nigeria?

1.4 Aims and Objectives

The sole aim of this research is to assess the level of use of Geosynthetics by construction stakeholders in the Nigerian Construction Industry. More so. to see if there is any available technical-know-how on the application and installation of Geosynthetic materials in construction works.

- To investigate the level of use of Geosynthetics by construction stakeholders in Lagos state.

- To assess the factors influencing the use of Geosynthetic materials by stakeholders in Lagos state.

- To evaluate the factors affecting the use of Geosynthetic materials by stakeholders in Lagos state.

- To ascertain if there is a relationship between contractors, consultant and clients in the use of Geosynthetic materials in Lagos State Nigeria.

1.5 Justification of the Study

Some parts of Lagos state in Nigeria are characterized with the problem of low bearing soil capacity are faced with the problem of low bearing soil capacities as this challenge has given way for exploring other soil stabilizing methods. Researchers in the Geotechnical field is faced with the challenge of substituting methods of soil stabilization such as the use of embarkments, use of raft foundation, pile foundation with Geosynthetics. With the principal view of its characteristic strength and durability, researchers have carried out an experiment on Geosynthetics on how to improve its characteristics strength to be used in soft soil.

Furthermore, the level of awareness in contactors will affect greatly the recommendation, usage and application of Geosynthetic materials to Construction works. There are few sites that have the application and usage of Geosynthetics on soft soils in Nigeria. As a result of the increase in technology and technological advancement, the use of Geosynthetics by contractors daily across the globe is increasing significantly (Rao, 2016).

Windapo and Iyagba, (2007) opined that there is a strong relationship between housing construction cost and the building material price, property price, money supply, national disposable income, labour cost and exchange rates. Therefore, building materials are therefore one of the major predictors of future cost housing and infrastructures in Nigeria. A shift to the usage and application of construction local materials will adequately result in a possible reduction in construction cost in Nigeria and will finally promote affordability of building housing.

Ghosh, (2009) discussed that man-made geotextiles of petrochemical constituents have a challenging eco-compatibility. She identified that locally made geotextiles from plant fibres possess eco-friendliness with the environment. With the light of this eco-friendliness, it was discovered that there are problems associated with the use. She discovered that either slowly or quickly, there is a certainty that the natural geotextile will deplete or wear off This is a big challenge to engineers and this has controlled the use of the material in some of the various ways of engineering applications.

According to Rudramurthy and Vikram, (2016), there is a sure increase in the CBR values of soil reinforced with geotextiles. They in their papers carried out an experiment on the bearing ratio capacity of selected soils and the effect of geotextiles as reinforcement to the soil. It was discovered that there is a sure increase in the bearing values of the selected soils and this paved a way for the use of geotextile materials for reinforcement.

Geosynthetic Institute (GSI, 2015) published that “the national and global status of geosynthetics-aware of graduating engineers, as well as new employees entering into geosynthetics design and consulting organization, is presently not only weak. but shows no promise improving” The institute stresses that all graduating members of civil engineering and all new employees have a little knowledge of the plethora of available geosynthetic materials including the various applications they serve. It was discovered that the field of engineering is graduating numbers of student yearly both at the undergraduate level and postgraduate level with the knowledge of the geosynthetic material and the various ways of application of the materials.

However, several publications have been published on geosynthetics including geotextiles as well discussing their physical and mechanical properties, the effect of geotextile on CBR values, and the need ‘for natural geosynthetics but there has not been a publication on assessment on the use of geosynthetics (geotextiles) by construction stakeholders. Hence, there is a need for an assessment on the use of geosynthetic materials by construction stakeholders in the Nigerian construction industry taking Lagos state as a case study.

1.6 Scope of Study

The research is limited to construction and housing development carried out by construction professionals and stakeholders (i.e. client, consultants and contractors) in Lagos state Nigeria. The research will equally cover the major factors contributing to the usage of Geosynthetic materials and other areas of application.

1.7 Definition of Terms

Geosynthetics are materials made from a planar, polymerics (either synthetic or natural) material used in contact with the soil or rock and any other geotechnical material, for filtration, drainage, separation, reinforcement, protection, sealing and packing (Rao, 1997)

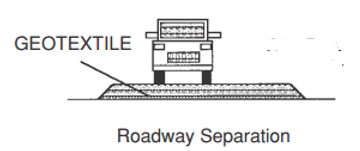

Geotextiles are permeable or impermeable fabrics used with the sol so as to protect, filtrate or reinforce the soil.

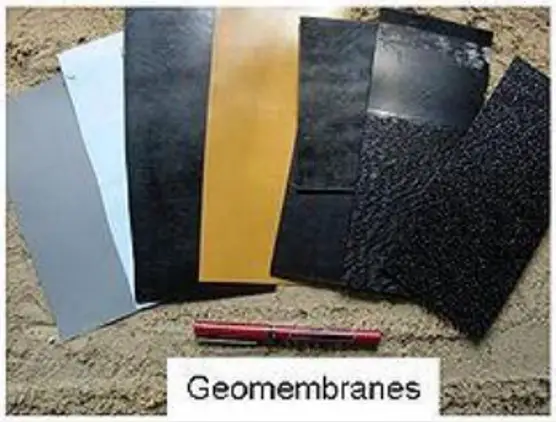

Geomembranes are continuous liner membranes used to control fluid migration from one layer to the other.

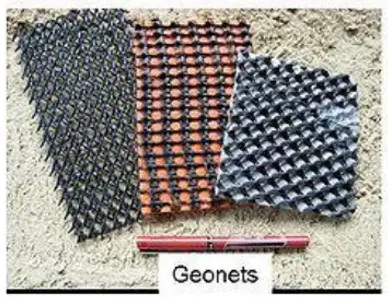

Geonets are polymer meshes or wires.

Geogrids are single plane structures with sufficient opening size to allow interlocking with the surrounding material.

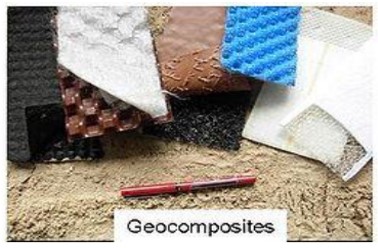

Geocomposites are earth fabrics used for specific application comprising of geotextiles and other geomaterials.

2. REVIEW OF RELATED RESEARCH LITERATURE

2.1 Introduction

The Construction Industry is described by Myers, (2013), as an intelligent multifaceted complex Industry. As put forward by Myers, the Construction Industry comprises of various firms or professionals involved in achieving the set goal of executing building construction works. Olanrewaju & Abdul-Aziz (2015) opined that giving no argumentative discussion, that the Construction Industry’s role is broadly known for prosperity and better stimulation of the economic development.

In support, (Myers, 2013; Hindle, 2000) put forward that the Construction Industry is so hierarchical in nature and fragmented in both practices and in nature so that the participating professionals do not consider themselves to be included as part of the same Industry. To achieve a better performance, it was opined by Toole (2013) that in achieving better output performance, among the fragmented professionals, this requires a close check and close coordination among a quite large number of specialized but apparent interdependent organizations and various individuals to achieve the absolute cost, time frame and desired quality goals required of the construction project.

According to (Geotextiles, n.d.) a publication released by fibertex non-woven: design, use and installation guidelines in Dalborg Denmark, it was opined that the use of Geotextiles has become well known and it’s becoming an increasingly integral part of structural designs and solutions. This tends to give hope to the sporadic demand and use of Geotextiles by the Construction Industry.

2.2 Historical Background to the Use of Geosynthetics

Textiles were first used as reinforcement to roadways in the days of Pharaoh the king of Egypt, the heroic deeds of the use of natural fibre geotextile for construction works can be traced back to early 5th and 4th millennia B.C as described in the Holy Bible wherein dwellings were formed from clay bricks with straw as reinforcement (Pritchard, Sarsby, & Anand, 2000). “Straw” is termed nowadays as fibers got from plants.

More so, they of pharaoh’s era struggled with unstable loose soils which gets washed away easily during erosion or water runoff. With the challenge they faced, they technologically found out that natural fibers, fabrics or vegetation improves road and soil quality particularly loosed soil (Pritchard et al., 2000).

Plant fibers and vegetation are of great importance to humanity and since the conception of the universe, Human beings have been exploiting the good out of nature. The use of geotextiles arises when there is need to reinforce/strengthens soil functioning as a structural element when subjected to loadings.

Agar-Quf formerly known as “the ancient city of Dur-Kurigazu” is a surviving example of structures that has material strengthening by natural fibers. More so, the great wall of china falls under the same category of surviving structures. The former fortress is known to have been founded since around 4th century BC. This Dur-Kurigalzu fortress has a height of about 52 meters with natural fiber as reinforcement to strengthens the soil under the structure. (Haghi, n.d.)Some publications on the great wall of China also stresses that, the great wall has its soil stabilization with plant fiber geotextiles to strengthens the under-layer soil beneath the structure.

The construction industry is not left behind in the use of geotextiles and the general geosynthetic applications to construction works as there has been further development and better method of producing geosynthetics that can be adopted and used for various works and various area of application has been got through research findings.

(Haghi, n.d.) opined in one of his publications that it is only recently as research work progresses that Geosynthetic materials have been used and exploited for modern road construction. This basic fact clarifies the confusion over terms, gives a better definition of geotextiles and gives an illustrative discussion on geotextiles common roadway and better erosion control applications.

Additionally, Venkatappa Rao & Banerjee, (1997) in their findings published that the use of geosynthetic materials by contractors and Engineers is daily increasing and there is a global increase in the use, application and installation of geosynthetics. As put forward, the use of Geosynthetic materials is increasing daily and this implies that in the nearest future, Geosynthetic market will thrive high as demand increases daily.

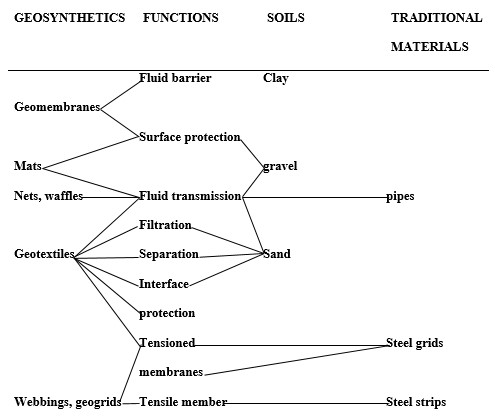

2.3 Review of Geosynthetic Materials and it’s Various Types

Schlosser, Delmas and Unterreiner, (1994) stated that geosynthetic materials are classified into; geotextiles and related products and geomembranes and related products. The product from the textile industry is named geotextile conversely, the product made from polymer or bitumen or bentonite are referred to as the geomembranes. The former which is called the geotextile is made from either natural fibres or synthetic fibres (Schlosser et al., 1994).

(Haghi, n.d.) establishes that there have been some derived basic confusions regarding the definition of the term “geosynthetics”. Authors put forward different definitions to suit the word “geosynthetics” and reviews have been done to establish the generally accepted definition for geosynthetics.

Rao and Banerjee, (1997) define geosynthetic materials as a synthesized civil engineering material for use with geological materials such as rock, soil or any other geotechnical engineering-related material so as to improve the properties and behaviour of civil engineering works.

According to Horrocks and Anand, (2000), geosynthetics, as used in the field of engineering, are said to be described as membranes used in contact with the soil or used in-between the soil. With respect to this, the definition is limited to the soil alone and this renders it not full enough to describe a “geo” meaning earth material. It ought to encompass all earth materials like rocks and others.

In view of the limitation, to the term geosynthetic, Rao, (2016) defines Geosynthetics as a planar, polymeric (either synthetic or natural) material used in contact with soil/rock and/or any other geotechnical material, for filtration, drainage, separation, reinforcement, protection, sealing and packing.

Furthermore, a Geosynthetic material can either be permeable or impermeable. Some authors further classify both types based on the type of materials used. In view of either permeability or impermeability, Geosynthetic materials can be categorically grouped into two according to their materials which are geotextiles and geomembranes and all their related products.

2.3.1 Geotextiles related products

Geotextiles are made either woven or non-woven depending on the method of production and applications. Horrocks and Anand, (2000) give five classifications for geotextiles based on production methodology which includes; woven, heat-bonded nonwoven, needle punched non-woven, knitted and by fibre/soil mixing.

2.3.1.1 Woven geotextiles

These textile fabrics are made textile looms which imparts a regular rectilinear construction to the fabrics with variation in terms of component fibres and weave construction (Horrocks and Anand, 2000). Woven fabrics are basically formed from either animal or plant fibres naturally. The natural fabrics already invoke includes; Henqueen, Viscose, Jute, Sisal, Coir, Flax, Hemp, Ramie, Cotton, Wool, Abaca and Polyester (Horrocks and Anand, 2000).

2.3.1.2 Heat-bonded nonwoven geotextiles

These fabrics results into the formation of a thin sheet of textile made from a continuous filament of fine fibres laid randomly on a moving belt which is thereafter passed between heated roller systems. The strength is achieved from the partial melting of fibres between hot rollers (Horrocks and Anand, 2000). It tends to possess more coherence and strength more than woven textiles.

2.3.1.3 Knitted fabrics

These are generally used in the field of geotextiles and engineering at large but are restricted to the warp-knitted fabrics generally because of its purpose in the engineering field. The knitting machines have the capabilities of producing fine filter fabrics, medium graded meshes and large graded diameter soil reinforcing grids (Horrocks and Anand, 2000). The knitted fabrics are found out that its high strength end range is cost-effectively used to reinforce the soil and carries out embankment support functions.

2.3.2 Natural geosynthetics

Venkatappa Rao & Banerjee, (1997) put forward that various Geotextiles made of natural fibres such as jute. Coir and sisal are all emerging as an available alternative to polymetric Geotextiles which its application involving temporary or non-critical structures where the shelter life span it’s may seem manageable and considerably manageable: Jute, Flax, Coir, Hemp, Straw, Sisal

2.3.2.1 Jute

Jute is natural multifilament fibre, durable and simple to both produce and disposes of. Biodegradable woven jute is accessible in a number of weave densities, initially anticipated as a geotextile to avoid land sliding and consequent to deforestation. Jute is available in India in large quantities at a cheaper rate. Jute geotextiles can perform a vital function in the control of soil erosion by revegetation and it has many uses, which are cheaper as well as easy to accomplish. It has the following uses

- It has many benefits as geotextiles, because of its high-water absorption capability, flexibility and drapability.

- It is also mixed with other materials, such as in the construction of jutes and-mat structures.

- The growth of jute-based geotextiles is huge due to its various applications in infrastructural development.

- Jute, one of the oldest surviving agro-industries in India, has been traditionally in use for flexible packaging, especially sacks.

- Jute geotextile is one such diversified product of jute which has proved to be highly effective in addressing a number of soil-related problems in civil engineering

Functionally, Jute geotextile does not have any dissimilarity with manmade geotextiles commonly known as synthetic geotextiles – made of artificial fibres with various Petrochemical derivatives as their sources. The functions are – separation, filtration, drainage and initial reinforcement.

2.3.2.2 Flax

Flax is a natural insulation material produced from flax fibres, intertwined together into non-woven matting, which can then be set in lofts or put into wall cavities. Coir geotextiles are applied in areas of erosion control, soil conservation, and other civil and bioengineering applications. It also has the appropriate strength and toughness to protect the slopes from erosion while permitting vegetation to flourish. They can dissolve the energy of flowing water and absorb the extra solar radiation.

2.3.2.3 Coir (coconut)

Used or recycled goods of the coconut fibres from the post-industrial waste can also be applied as the economical applicators. It gives low impact and reasonable result to the problems of soil erosion and land sliding on manmade slopes such as motorway and railway embankments.

2.3.2.4 Cotton

Cotton is mainly made from old clothes in the form of recycled cotton or from the post-consumer waste stream, it is available in a broad variety of colourways, each having the feature of speckling due to the lack of discrimination during the recycling and sorting stages of production.

2.3.2.5 Straw

Produced by a mixer of straw and a loosely woven net of the biodegradable string gives a minimal influence and realistic answer to the problems of soil erosion and land sliding on manmade slopes such as motorway and railway embankments.

2.3.2.6 Kevlar

Woven Kevlar textiles possess the structural dynamics and work better than steel, but with a fraction of its weight. Whether it is working in a plant or handling sharp edge materials Kevlar bring together high strength (5 times stronger than steel) with lightweight, and comfort with protection. Kevlar is also made at low temperatures. They are applied as the reinforcement of cement concrete in the form of chopped fibres both for ordinary and autoclave cure types. Kevlar can also be used with other materials as a protective coating.

2.3.2.7 Polyester

Made from the post-consumer wastes such as bottles, fabrics, etc. in the composition of polyester ethylene terephthalate, and because of its superior strength and elasticity, it is applicable to numbers of geotechnical applications.

2.3.2.8 Polypropylene

Polypropylene is a famous alternative for geo-grids or geometrics, as it is strong and chemically static. Polypropylene is accepted to carry out poor long-term creep behaviour but is economical and light in weight.

2.3.2.9 Phenolic/jute composite

This composite is a strong and abundantly durable, made by the mixing of jute fibres with a phenol-based resin binder. Bio-composites such as this one give a substitute for making durable, high-performance materials whilst applying as few non-renewable as probable. This material is extensively applicable within a range of furniture design applications. Besides these, many other types of materials may be applied to make geotextiles, according to its applications. Geotextiles are more and more applied in civil engineering works and so their production has new openings to the textile industries.

2.3.3 Artificial geosynthetics

These are Geomaterials made from polymers as a result of the following factors which includes; ease of manufacture, economic consideration and the range of properties applicable to civil engineering structure (Venkatappa Rao & Banerjee, 1997). Therefore, the most common type of polymer implores in the manufacture of acritical Geosynthetic are polypropylene(Polyolefin), Polyethylene, Polyester, Polyvinylchloride and Elastomers (Venkatappa Rao & Banerjee, 1997).

The polyolefin fibres have technically been proven to be the most attractive of all the remaining fibres all because of their low cost and inert nature. This signifies that major proportion of Geosynthetics available today in Geosynthetic market are made from polypropylene. The critical disadvantage of polypropylene fibre is its susceptibility to creep and Ultra Violet light degradation (Venkatappa Rao & Banerjee, 1997).

The polyester fibres possess high young’s modulus, low susceptibility to creep factor and zero or no variation in its mechanical properties at high temperatures near 180-200oC. However, they are found to be chemically inert in the sea and in weak acids (Venkatappa Rao & Banerjee, 1997).

Venkatappa Rao & Banerjee, (1997) classify artificial Geosynthetics into the following for better understanding of its application and usage. These include; Geomembranes, Geogrids, Geonets, Geocomposites, Geomatics, Geocell and Biomat

2.3.4 Geomembranes

Rao & Banerjee, (1997) describes Geomembranes as a continuous liner membrane composed of materials which ae of low permeability in order to control fluid migration from one layer to another layer and it does a separation work in this regard. Materials used for its production are asphalt and polymers, and in some cases, the combination of both asphaltic or polymeric.

However, Geomembrane is a form of Geosynthetics applied mainly to construction sites as linings and covers of liquid or solid-storage facilities. They are known and used as resistant materials, it is basically produced in the shape of the manufactured sheet which may either be synthetic or bituminous. The main task it is expected to perform is as a liquid or vapour barrier. and recognized as flexible geomembranes as liners besides, having water containment capabilities and because of its impermeability characteristics, its applications can be found to include; waste containment, ponds, swimming pools, etc.

Geomembranes has advantages which includes;

- It provides a barrier in waste containment facilities and in various landfills due to various benefits associated with their use and because of regulatory requirements.

- It is increasingly being used in water and oil reservoirs, ponds, lined canals and other geotechnical projects.

- Geotechnical engineers often characterize the shearing resistance along with the interface between geomembranes and soils using results from interface direct shear tests.

The results of these tests are used in an analysis of stability against sliding along the given interface. Interface shear testing between soil and geosynthetics has now become an essential part of the design process in geotechnical and geoenvironmental engineering. They are made from thin sheets of rubber or polymeric material used primarily for linings and covers of liquid or solid waste containment facilities.

2.3.4.1 Geogrids

This is a structure lying on a single plane formed by a consistent regular framework of tensile elements with sufficient opening size to allow interlocking with surrounding geological material is it soil or aggregate. They possess high stability, considerable high strength and significant-high tensile modulus with low elongation.

Geogrid as a type of Geosynthetic material is a polymeric structure. they are single or multi-layer materials usually made from extruding and stretching high-density polyethylene or polypropylene

or by weaving or knitting and coating high tenacity polyester yarns. The resulting grid structure possesses large openings (called apertures) that enhance interaction with the soil or aggregate. It has its raw material to be a polymer rather than being made as a woven, nonwoven or knit textile fabric, in their unidirectional or bidirectional format. They are made in the form of manufactured sheet, including a regular network of integrally associated parts, which may be linked by extrusion, bonding or interlacing, whose openings are larger than the constituents, made into an extremely exposed, network like the arrangement, i.e. they have large apertures.

- They work as reinforcement materials.

- Coated polyester geogrids have been broadly applied in soil stabilization and geotechnical reinforcement uses.

- Having a great deal of tensile strength in one direction (longitudinal or transversal) than in the other direction. Having identical strength in both longitudinal and transversal direction.

- Created through stretching uniaxial or biaxial, an extruded integral structure. Created through bonding, at right angles, two or more sets of strands.

2.3.4.2 Geonets

Geonets are polymer meshes or wires that has similar correspondence to Geogrids but of lower strength (Venkatappa Rao & Banerjee, 1997). In comparison with Geogrids these are having lesser strength. They are applied in relation to hydraulics as they are used to drain water in a horizontal plane.

Geonets are made of stacked, crisscrossing polymer strands that provide in-plane drainage. Nearly all geonets are made of polyethene. The molten polymer is extruded through slits in counter-rotating dies, forming a matrix, or “net” of closely spaced “stacked” strands. They are normally made by uninterrupted extrusion of corresponding sets of polymeric ribs at acute angles to one another. When the ribs are opened, relatively large apertures are shaped into a netlike pattern. Their pattern work is mostly applicable in the drainage area.

- Geonets are the most recently introduced members of the geosynthetic family.

- They are grid-like materials which are distinct from Geogrids by virtue of their function.

- They do have considerable strength but are used mostly for drainage purposes.

- All Geonets are made of polyethylene.

- The specific gravity of most geonets is in the range of 0.935 to 0.942.

- The only other materials in geonets are carbon black and a processing package.

Diamond-shaped apertures are formed that are typically 12mm long by 8mm wide. Geonets are typically 5.0 to 7.2mm thick. Thickness is a key factor in determining drainage capability. Adding a foam agent to the ingredients can increase thickness of geonets

2.3.4.3 Geocomposites

Venkatappa Rao & Banerjee, (1997) postulates that when geotextiles or Geogrids or Geomembranes are combined either directly or indirectly with woven or nonwoven Geotextiles or Geogrids for specific applications such as drainage works, erosion controls, bank protection construction, etc., they are referred to as Geocomposites. Literally, Geocomposites involves the use of two non-homogeneous materials together.

A geocomposite comprises with a mixture of geotextile and geogrid; geogrid and geomembrane; geotextile; or any of these three materials with another material (e.g. deformed plastic sheets, steel cables, or steel anchors). Geocomposites are accumulated materials, in the appearance of manufactured sheet or strip, compromising of at least one geosynthetic among the components.

2.3.4.4 Geomat

Geomat is available in the polymeric form, in the shape of a manufactured sheet, compromising of an irregular network of fibres, yarns, filaments, tapes or other elements (thermally or mechanically connected), whose openings are normally greater than the application of the constituents.

2.3.4.5 Geocell

Geocell is available in a polymeric cellular form including a regular open network of connected strips, linked by extrusion, adhesion or by other methods.

2.3.4.6 Biomat

They are permeable, natural, and accepted as biodegradable polymeric materials, in the shape of a manufactured sheet. Normally, biomat comprises with fibers (jute, coir, sisal, straw, or others) set aside collectively by one or two layers of synthetic or natural meshes and bionet comprises with a regular network of knotted or interlaced yarns, whose openings are normally greater than the constituents.

2.4 Review of Various Geosynthetic Material Applications

According to European and International Geotextile Standards, (2014 revised) eleven key standards has given light into the various ways of Geotextile applications and these includes; roads and other trafficked areas (EN13249), Railways (EN13250), Earthworks, foundations and retaining walls (EN13251), Drainage systems (EN 13252), Erosion control works (EN 13253), Reservoirs and dams (EN13254), Canals (EN 13255), Tunnels and underground structures (EN 13256), Solid waste disposals (EN 13257), Liquid waste containment (EN 13265) and Asphalt reinforcement (EN 15381).

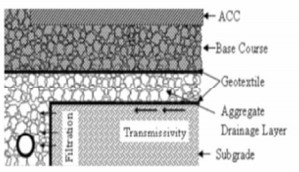

2.4.1 Application to Road and other Trafficked Areas (EN13249)

Research has shown that as a result of the challenges faced by geotechnical engineers in soft soil landfills and embankment, it is expedient that such soil is reinforced with an economical and a sustainable material. It is required of the standard that; a geotextile material must be suitable for road construction works such as in other trafficked areas. With respect to the possessed tensile strength, it is expected of geosynthetic materials to act in roads and other trafficked area. According to findings by Wulandari and Tjandra (2015), the use of geotextile materials as reinforcement in road embankment and in soft soil has increased. Applying a particular factor of safety, the tensile strength of the geotextile materials increases.

2.4.2 Earthworks, foundations and retaining walls (EN13251)

Geotextile material can be applied to earthworks, foundations and retaining walls. The European standard sets out the minimum standard of performance for the geotextile materials to fulfil the purpose of its application with respect to earthworks, foundations and retaining structures.

2.4.3 Railways (EN13250)

For effective use in railway construction, the geotextile material must possess high tensile strength, puncture resistance, permeability, elongation properties to a considerable level of performance.

2.4.4 Drainage systems (EN 13252)

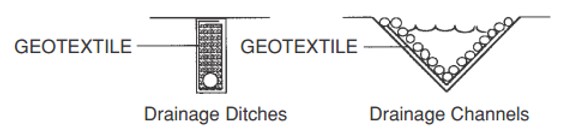

Among the various uses of geotextile materials, application to a drainage system is paramount to some countries where the material is used inside the road drains. It can be applied to drain ditches and inside respective drainage channels. According to the European standard, a geotextile produced in accordance with this standard must be able to perform this function during its service years without failure.

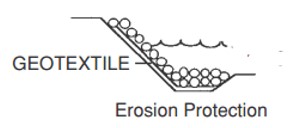

2.4.5 Erosion control works (EN 13253)

Locally made geotextiles such as jute and sisals have helped in controlling erosion about 20 to 30 decades ago. With the advent of research and more findings, there has been an improvement in the properties of all these materials and better performance enhancement for geotextiles with respect to erosion control.

2.4.6 Reservoirs and dams (EN13254)

An improvement in the performance of geotextiles has led to its ability to be used in reservoirs and dams concurrently without failure. In recent times, geotextiles have been functioning well in dams and in reservoirs. The best applicable type of geotextile here is impermeable in as much as water is not allowed to pass through at all. The European standard states all regulations regarding the production of these materials so as to perform the intended function without failure.

2.4.7 Canals (EN 13255)

Geotextile liners have been developed to contain water in canals for artificial waterway for navigation as well as irrigation for farmers and the local places of a particular region. The development in this area has made it possible for canal application. The European standard specifies the requirement for these materials in order to serve these purposes without failure or fracture.

2.4.8 Tunnels and underground structures (EN 13256)

The European standard specifies the requirements for geotextiles in accordance to the usage in tunnels and underground structures. Geotextiles are expected to serve duly throughout their service years without failure or fracture to the structures. These is enhanced through the characteristic strength of all these materials. It possesses good physical and mechanical properties so as to withstand all the imposed loads coming on it.

2.4.9 Solid waste disposals (EN 13257)

Geotextiles have been used to contain solid wastes in an embankment. Some developed countries embark on the usage of geotextiles and geogrids for solid waste landfills and embarkment. To avoid solid waste loitering the environment, geosynthetic materials are used to gather solid waste together before recycling or disposing them to the right places. The European standard specifies the minimum requirements for these types of geosynthetic with respect to their strength and mechanical properties.

2.5 Technical Functions of Geotextile Materials

Geotextile material used in any of the above-named applications must fulfil either one or more of the following functions which are; Filtration, Drainage, Reinforcement, Separation, Protection

2.5.1 Filtration

Geotextile material is used in filtration purposes when applied to waste embankments. The geotextile material used in the waste embankment and landfills carries out the function of filtration along the plane. This is preferred in terms of waste landfills and waste embankments.

2.5.2 Drainage

The primary purpose of the use and the application of geotextile is to be used as either in landfills or inroads. Alongside this purpose, it carries out the function of drainage due to its porosity and varying opening sizes for the material. The opening size of the geomaterial determines its ability to serve the purpose of drainage.

2.5.3 Reinforcement

Researchers have done great justice to this end and it has been discovered that geotextile materials have the ability and potential to serve as reinforcement to soft soils. Wulandari and Tjandra (2015), developed a 2D Plaxis model for different types of soils and using geo material as reinforcement at two different layers, it was discovered that with a given factor of safety, the tensile strength of the geotextile material increases and this causes an increase on the CBR value of the tested soil.

2.5.4 Separation and protection

In addition, geotextile material serves as a separating agent acting as a barrier to two different layers of soil or earth material. Geotextile cannot serve the function of separation alone but it must be with another material such as the geocomposite.

It serves as a protecting agent when used in combination with a geosynthetic barrier.

2.6 Geosynthetic Functions Versus Applications

Table 1: The table showing different functions against applications of geosynthetic materials

| Standards | Application | F | D | R | S | P | STR | B |

| EN 13249 | Roads and other trafficked areas | √ | √ | √ | ||||

| EN 13250 | Railways | √ | √ | √ | ||||

| EN 13251 | Earthworks, foundation and retaining walls | √ | √ | √ | ||||

| EN 13252 | Drainage system | √ | √ | √ | ||||

| EN 13253 | Erosion control | √ | √ | √ | ||||

| EN 13254 | Reservoirs and dams | √ | √ | √ | √ | |||

| EN 13255 | Canals | √ | √ | √ | √ | |||

| EN 13256 | Tunnels and underground structures | √ | ||||||

| EN 13257 | Solid wastes disposal | √ | √ | √ | √ | |||

| EN 13265 | Liquid waste containment | √ | √ | √ | ||||

| EN 15381 | Asphalt reinforcement | √ | √ | √ |

Where F= Filtration, D= Drainage, R= Reinforcement, S= Separation, P= Protection, STR= stress Relief and B= interlayer barrier.

2.7 Relationships between Various Geosynthetic Products and their functions

Table 2: picture showing relationship between geosynthetic products and their functions

2.8 Review of Various Geosynthetic Testing and Evaluation

Anand, (2008), opined that geosynthetics can perform several kinds of functions individually or simultaneously in conjunction with other materials. This relies on their possessing power for structural properties, physical properties, mechanical and Hydraulic properties. He further stresses on basic functional requirements of geosynthetic materials which involve all properties mentioned earlier.

According to Venkatappa Rao & Banerjee, (1997), geosynthetics needs to be assessed by testing before recommendation for use in construction so as to be sure of it’s the ability to serve specific functions stated earlier.

Furthermore, for quality control during the production stage and at the construction stage, geosynthetics must serve and attain the required standards before use.

To achieve the required standards through testing, various properties of geosynthetics are reviewed such as; Physical properties, Mechanical properties, Hydraulic properties, Constructability/ Survivability properties, and Durability properties.

Table 3: functional requirements for reinforcing geotextiles

| Properties | Requirement status | Properties | Requirement status |

| Tensile strength | HI | Creep | HI |

| Elongation | HI | Permeability | N-MI |

| Chemical resistance | I-HI | Resistance to flow | MI |

| Biodegradability | HI | Properties of soil | HI |

| Flexibility | MI | Water | HI |

| Friction properties | HI | Burial | HI |

| Interlock | HI | UV light | I |

| Tear resistance | MI | Climate | NA |

| Penetration | MI | QA & control | HI |

| Puncture resistance | MI | costs | HI |

| HI- Highly important, | I-Important, | MI-Moderately important, | NA-Not applicable |

2.8.1 Physical properties

The physical properties of geosynthetic materials are referred to its properties which can be observed or measured without changing the composition of the materials so as to be able to describe how the materials look like. With respect to this, the physical properties related to this material includes; Specific Gravity, Mass per Unit Area, Thickness and Stiffness

2.8.1.1 Specific gravity

This is a measurable property of this material in relation to a unit volume of water.

It is the ratio of the substance unit volume weight to that of distilled water. The instrument used for measuring specific gravity is pycnometer. This property is significant when dealing with applications of water penetration, water absorption and filtration functions.

2.8.1.2 Mass per unit area(g/m2)

The unit mass of a geosynthetic material is a measurable property for achieving the knowledge about the weight of a unit surface area per square meter. The weight of one gram of a geosynthetic material per one-unit area is used to know the cost of production and as well be able to determine the bulk weight of the overall weight of the materials.

This is the ratio of the mass of the substance to area of the substance.

2.8.1.3 Thickness

The roll thickness of geosynthetic materials is used to determine its ability to be able to withstand loads coming on it. A higher thickness of geosynthetic material is going to withstand a considerable load or force tan a smaller section of the same geosynthetic materials.

This is the clear distance between the upper and lower surfaces of a fabric expressed in millimetres‘ mm’.

2.8.1.4 Stiffness

This is the measure of the interaction between fabric weight and its bending stiffness.

2.8.2 Mechanical properties

The mechanical properties of a geosynthetic material are used to classify and identify the type of geosynthetic it is. The most important properties of a geosynthetic material in its mechanical properties. These properties speak in three-dimensional fundamentals so as to know which class the material belongs. The majorly considered properties mechanically for geosynthetic materials include; Compressibility, Tensile Strength, Seam Strength, Fatigue Strength, Burst Strength, Tear Tests, Impact Tests, Puncture Tests, Friction Behavior and Pullout Tests

2.8.2.1 Compressibility

The compressibility of a material is the measure of the relative volume change of the material with the response to a change of pressure. This is the variation of the thickness of geotextile at different normal pressures. It is seen to be constant always at normal pressures. This property is needed so as to determine the response of geosynthetic materials when loads are applied to them.

2.8.2.2 Grab Tensile Strength

This is the test used to ascertain the construction survivability of the geosynthetic materials. This is used to determine or ascertain the breaking load and elongation of the material so as to determine its effective strength. This property helps to see into the future life of the geosynthetic materials

2.8.2.3 Tensile Strength Tests

These have different tests such as the wide width tests and narrow strip test. It is measured in force per unit width in relation to the strain at peak load. It is also called a tension testing where the geosynthetic material is subjected to a controlled tension until failure of the material. This is used to affirm the peak load and peak strength of the material.

As reviewed in the above table the tensile property of a geosynthetic material is Highly Important.

2.9 Review of Factors Influencing the use of Geosynthetics

The selection of construction materials by designers, architect, engineers and clients for construction purposes is being influenced by the following factors of performance of the materials which includes; Strength, Biodegradability and durability, Flexibility and availability, Good elongation properties/workability, Creep properties, Soil properties, Cost of the material, Quality Assurance and control and Ease of transportation.

2.9.1 Strength

Some authors and designers resolved to the use of geosynthetic materials because of their good characteristic strength. The first considered factor influencing or aiding the choice of geosynthetic materials over other materials is their strength. Some authors put forward that geosynthetic materials can have strength as high as 100KN to 1000 KN. On average, a geosynthetic material can have strength more than 100 KN and this makes it possible to be used as reinforcement.

2.9.2 Biodegradability and Durability

Eco-friendliness and green building is the order of the day in the which some designers chose geosynthetic materials because its degradable without causing any harm to the environment at large. It is believed by some authors that geosynthetics are durable and should be encouraged in the usage.

2.9.3 Flexibility and Availability

Ease of installation and availability is a major determinant factor to the choice of geosynthetics. Some designers agreed that their choice on geosynthetics is all because they are flexible and this makes the installation easier coupled with technical know-how. Another agent is how abundance or available is the material. Some engineers agreed that if these materials are available and cost-effective, that will aid the selection of these materials.

2.9.4 Soil Properties

The state of the soil in terms of bearing capacity is the reason for either choosing or not choosing the geosynthetic materials. Some soils are very weak that using geosynthetic materials will not solve the problem and as a result, other alternatives are sourced to reinforce the soil. Whereas, a considerably stable soil can be enhanced with the use if geosynthetics.

2.9.5 Quality Assurance and Control

The assurance of quality with respect to the workmanship and technicality behind the installation is another factor to be considered in selecting these materials. It is believed by some engineers and clients that once quality is assured, the usage of these materials is enhanced and encouraged.

2.9.6 Cost of the Geosynthetic Material

The major determinant factor in material selection is the cost of procuring those materials. Some authors agreed that the cost of geosynthetic materials is considerable with respect to its characteristics strength. With a considerable cost per square area, clients will be encouraged to use these materials and designers will be motivated to specify them for usage at the design stage.

2.9.7 Ease of Transportation

Clients and designers at the early stage of selection consider reasonably the ease with which the materials to be used for construction will be transported to the site without incurring too much cost on transportation. The easier it is to get the materials for usage, the higher the chances for selecting the materials for construction works.

2.10 Review of Factors affecting the use of Geosynthetics

In selection processes of construction materials, there are major factors that hinder the use of these materials by the architect client and engineer at the design stage of the construction work. These factors affecting the use and hindering the stakeholders from selecting them for construction purposes include; site consideration factors, Economic Factors, Environmental factors and Stakeholders’ contributive factors. All these factors have been selected to be affecting the selection and use of these geosynthetic materials.

2.10.1 Site consideration factors

Some authors discuss that the major factor hindering the choice of construction materials is the site condition which is in two parts 1. Location of site and 2. Site distance/proximity. The distance of the site to access roads to the main roads in conjunction with the cost of moving those materials prevents designers from selecting those materials.

2.10.2 Economic factors

Authors opined that economic factors constitute to the choice of materials largely all because procurement cost of these materials depends on the clients and the clients want a considerably cheaper material. The economic factors observed include; Cost of geosynthetic construction material, Unstable price of materials, Transportation cost, Equipment cost, Life-cycle cost, affordability, Labor cost and Economic status.

2.10.3 Environmental factors

Environmental friendliness materials are preferred for non-eco-friendly materials. Designers consider the eco-friendliness of materials while selecting their suitability for the intended purposes. The following are the reviewed environmental factors and these are; Effect of weather, Environmental impacts, Environmental compatibility, Climate, Waste prevention and Water resistance

2.10.4 Stakeholders’ contributive factors

The contributive agreement of stakeholders while deciding on what material to use is of great importance. The stakeholders must attain a certain level of relationship right from the inception of the birth of the project to the conception of birth. Clients must agree to what decision the designer is giving and contractors must be able to deliver up to the expectation of what is being demanded. The following are the contributive factor on stakeholders which are; User/owner’s choice, working experience of designer or engineer, Capacity of the contractor, Change in design and Lack of relationship between designers and contractors.

3. RESEARCH METHODOLOGY

3.1 Introduction

Research methodology has appropriateness to either validates or invalidates a typical research hypothesis and consequently gives a conclusive result. This chapter discusses deeply into the following sub-topics as related to research methodology and statistical analysis generally: the research design, research population, research sampling techniques, research sampling frame, research sample size, research data collection, and research method of data analysis.

3.2 Research Design

As stated by Ellen (2009), the research design is/are the adopted method(s) to be implored in order to carry out typical research. The research methodological design for this project is basically structured on a survey method of qualitative and quantitative information from the population through the administration of structured questionnaires for their inputs and statistical analysis of this study to validate the stated objectives.

3.3 Research Study Population

According to Naoum (1999), Population is defined as “the group that has certain characteristics in common. Furthermore, the population is said to be a collection of total elements being studied about which conclusion(s) is/are to be drawn (Okoko, 2010). For the sake of this research, the population is referred to as the clients, professionals such as builders, Civil/structural engineers, Geotechnical engineers, estate developers, estate managers, quantity surveyors, architects who partook in the construction of some estates on Lagos Island.

This project has its study area in Lagos Island of Nigeria all because of the challenges of soft soil in this with low bearing capacities. The study area is located in the southwestern part of Nigeria with the coordinates of 6o27’16” N and 3o 23’31” E.

This study area was chosen as a result of the challenges being faced with soft soil in the geographical area. The bearing capacity of the soils in this area is considerably low and needs additional reinforcement.

3.4 Sampling Techniques

The questionnaires shall be administered to clients, contractors and consultants of the building industry within Lagos Island. The technique behind this research sampling being used is due to the peculiarities of the research problems.

A stratified and purposive sampling technique will be implored in this research.

3.5 Sampling Frame

Rather than obtaining information from the whole Lagos state construction stakeholders, completed estates are sampled out on the Island for the purpose of this research work due to the nature of the construction industry in the whole of Nigeria. The construction industry is too large to be covered under the scope of this study.

In this geographical area, the sampling frame for this research will be focusing on the contractors, consultants and clients or house owners in Victoria Island.

3.6 Sample Size

Data is defined as the facts or certain things known and from which conclusion can be drawn. Due to the fact that building construction activities are rampant in the cities that involve professionals in the private and public sectors, to determine the number of questionnaires to be administered for respondents, purposive sampling was used to administer 100 questionnaires to contractors, clients, and registered professionals in the construction field.

3.7 Data Collection Tool

Data are collected through the structured questionnaires administered to some selected stakeholders that involve directly in the building production to avoid discrepancies in the data to be analyzed while the secondary source of data are related journals in an attempt to achieve the objectives of the study

3.8 Method of Data Analysis

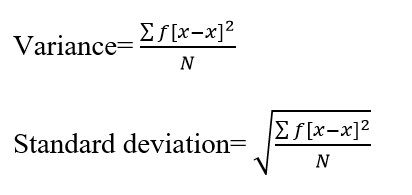

Two broad categories of methods or tools are available for the description and analysis of data in social science(s) research, namely descriptive and inferential statistics (Lapin, 1975; Sanni & Adedayo, 2003). A combination of both statistical techniques is engaged in the analysis of the collected data. Descriptive statistics embody methods for summarizing or describing data. They include frequency distribution, measures of central tendency (mode, median and mean) and measures of dispersion (range, mean deviation, standard deviation, quartile deviation and variance). Cumulative frequency distribution, the three measures of central tendency, standard deviation and ranking on the basis of mean item scoring are descriptive statistical techniques used for this study in connection with achieving the first three objectives.

In order to assess the factors both affecting and influencing the use of geosynthetic materials in this study, the classification of rating scales is used. The responses to the questionnaires are based on Likert scale of five ordinal measures which is from one to five according to the level significance. Likert scale is a widely used instrument in measuring opinions, beliefs and attitudes. The classifications of rating scales are as follows;

- 5 = highly significant

- 4 = significant

- 3= moderately significant

- 2 = slightly significant

- 1 = not significant

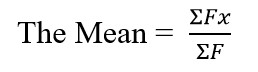

Mean

Mean can be defined as a central value such that both positive and negative deviations from it are intimately cancelling themselves out.

Formula:

Where F = frequency of each class

X = mid-point of each class interval.

Mode

Mode is defined as the observation which appears most frequently in a set of data.

Standard Deviation

This is the square root of variance which is represented as thus:

However, the use of statistical package for social science (SPSS) software version 18.0 is also employed.

4. DATA PRESENTATION AND ANALYSIS

4.1 Introduction

This chapter deals with the presentation of collected data and subsequent evaluation of such data. The data analysis was carried out with the use of descriptive statistics such as mean score, percentile and inferential statistics such as ranking and correlation. Finally, conclusions were drawn from the findings.

4.2 Data Presentation and Analysis

A tool of 100 purposive questionnaires were distributed within the study area of Lagos State Highland, out of which 76 were returned that represents 76% of the distributed questionnaires, 24 of the questionnaires were not returned.

4.2.1 Respondents Professional Qualification

The table below shows the demographic characteristics of the respondents

Table 4.1: type of professionals

| S/N | Profession | Frequency | Percentage | |

| 1. | Architect | 8 | 10.5% | |

| 2. | Builder | 12 | 15.8% | |

| 3. | Civil Engineer | 24 | 31.6% | |

| 4. | Estate Developer/Manager | 8 | 10.5% | |

| 5. | Geologist | 0 | 0.0% | |

| 6. | Geotechnical Engineer | 4 | 5.3% | |

| 7. | Marine Engineer | 4 | 5.3% | |

| 8. | Others | 0 | 0.0% | |

| 9. | Project Manager | 4 | 5.3% | |

| 10. | Quantity Surveyor | 12 | 15.8% | |

| Total | 76 | 100.0% |

The above table shows that a total of 76 professionals responded to the survey and as it is depicted above, Architect represents 10.5%, Builder is represented by 15.8%, Civil Engineer represents 31.6%, Estate Manager represents 10.5%, Geotechnical Engineer represents 5.3%, Marine Engineer represents 5.3%, Project Manager represents 5.3%, Quantity Manager represents 15.8%. This is an indication that the professionals involved in the Building Processes are well represented and has contributed to the research.

Table 4.2: Respondents Qualifications

| S/N | Qualification | Frequency | Percentage | |

| 1. | OND | 4 | 5.3% | |

| 2. | HND | 12 | 15.8% | |

| 3. | B.SC/B.TECH | 34 | 44.7% | |

| 4. | PGD | 0 | 0.0% | |

| 5. | M.SC/M.TECH | 26 | 34.2% | |

| 6. | PH.D | 0 | 0.0% | |

| Total | 76 | 100.0% |

Table 4.2 above shows the respondent’s qualification which depicts OND which represents 5.3%, HND represents 15.8%, B.Sc/B.Tech represents 44.7% and M.Sc/M.Tech represents 34.2%. This shows that the respondents are qualified enough to ascertain their perception about the construction materials.

Table 4.3: Respondents Professional Membership Affiliation

| S/N | Professional Body | Frequency | Percentage |

| 1. | CORBORN | 16 | 21.1% |

| 2. | COREN | 28 | 36.8% |

| 3. | NIQS | 12 | 15.8% |

| 4. | NIA | 10 | 13.2% |

| 5. | NGA | 0 | 0.0% |

| 6. | NIESV | 0 | 0.0% |

| 7. | OTHERS | 10 | 13.2% |

| Total | 76 | 100.0% |

Table 4.3 shows respondents with CORBORN as 21.1%, members with COREN as36.8%, members with NIQS as 15.8%, members with NIA 13.2%, members affiliated to other professional bodies as 13.2%. This connotes that the respondents are well affiliated and represented in their respective professional fields.

Table 4.4 Respondents Years of Experience

| S/N | Year of experience | Total | Percentage |

| 1. | 1-5 Years | 10 | 13.2% |

| 2. | 6-10 Years | 30 | 39.5% |

| 3. | 11-15 Years | 22 | 28.9% |

| 4. | 16-20 Years | 12 | 15.8% |

| 5. | Above 21 Years | 2 | 2.6% |

| Total | 76 | 100.0% |

Table 4.4 shows respondents with a number of years of experience. 13.2% of the respondents have 1-5 years of experience, 39.5% has between 6-10 years of experience, 28.9% has between 11-15 years, 15.8% has between 16-20 years of experience and 2.6% has years of experience above 21years. This depicts that respondents have fair judgment and deep construction experience over the years to ascertain the contributory factors influencing the construction materials.

4.3 Level of Awareness of Geosynthetic Materials

Table 4.5: level of awareness of geosynthetic materials

| S/N | Geosynthetic Materials | Mean Score | Rank | RII |

| 1. | Geotextiles | 4.300 | 1 | 0.91 |

| 2. | Geomembranes | 3.950 | 2 | 0.83 |

| 3. | Geonets | 3.675 | 3 | 0.77 |

| 4. | Geogrids | 3.425 | 4 | 0.72 |

| 5. | Geocomposites | 3.225 | 5 | 0.68 |

From the table above, the respondents are mostly aware of Geotextile materials with a relative importance index of 0.91 and mean score of 4.3 being rated as significant, followed by geomembranes with a Relative importance index of 0.83 and mean score of 3.95 the least known geosynthetic material is geocomposites with a relative importance index of 0.68 and mean score of 3.23.

4.4 Level of Use of Geosynthetics

Table 4.6: the level of use by stakeholders

| S/N | Geosynthetic Material | Mean | Rank | RII |

| 1. | Geotextile | 3.71 | 1 | 0.742 |

| 2. | Geomembranes | 3.34 | 2 | 0.668 |

| 3. | Geogrids | 3.32 | 3 | 0.663 |

| 4. | Geonet | 3.00 | 4 | 0.600 |

| 5. | Geo-liners | 2.76 | 5 | 0.553 |

| 6. | Geomats | 2.68 | 6 | 0.537 |

| 7. | Geocomposites | 2.66 | 7 | 0.532 |

| 8. | HDPE | 2.37 | 8 | 0.474 |

Table 4.2.3 shows the level of use of geosynthetic materials based on the respondents’ technical use and relevance to the construction industry, geotextiles are the most used materials among other related geosynthetic material with a relative index of 0.742 and mean score of 3.71, followed by geomembranes with a relative importance index of 0.668 and mean score of 3.34. from the respondent’s perception, geo-liners are the least used materials with a relative importance index of 0.553 and mean score of 2.76.

4.5 Factors Influencing the Use of Geosynthetics

Table 4.7: factors influencing usage by stakeholders

| S/N | The Factors | Mean | Rank | RII |

| 1. | High strength | 4.526 | 1 | 0.905 |

| 2. | Quality Assurance and control | 4.474 | 2 | 0.895 |

| 3. | Biodegradability | 4.421 | 3 | 0.884 |

| 4. | Soil properties | 4.368 | 4 | 0.874 |

| 5. | Creep properties | 4.342 | 5 | 0.868 |

| 6. | Flexibility | 4.316 | 6 | 0.863 |

| 7. | Good elongation properties | 4.211 | 7 | 0.842 |

| 8. | Cost of the material | 4.132 | 8 | 0.826 |

Table 4.7 shows the rank as depicted by the respondents on the factors influencing the choice of using geosynthetic materials for construction purposes. The table shows high strength as the most ranked influencing factors with a relative importance index of 0.905 and mean of 4.526, followed by quality assurance and control as the second most influencing factor affecting the usage with a relative importance index of 0.895 and mean score of 4.47, thereafter biodegradability is the next ranking factor with relative importance index 0.884 and mean score of 4.42 as shown above, cost of the material is the least ranked influencing factor with a relative importance index of 0.826 and mean score of 4.132.

4.2.5 Factors Affecting the Use of Geosynthetics

Table 4.8: affecting factors

| S/N | Affecting Factors | Mean | Rank | RII | |

| 1 | Effect of weather | 4.737 | 1 | 0.947 | |

| 2 | User/owner’s choice | 4.632 | 2 | 0.926 | |

| 3 | Cost of geosynthetic construction material | 4.605 | 3 | 0.921 | |

| 4 | Water resistance | 4.500 | 4 | 0.900 | |

| 5 | Working experience of designer engineer | 4.447 | 5 | 0.889 | |

| 6 | Location of site | 4.447 | 5 | 0.889 | |

| 7 | Environmental impacts | 4.421 | 6 | 0.884 | |

| 8 | Environmental compatibility | 4.368 | 7 | 0.874 | |

| 9 | Affordability | 4.316 | 8 | 0.863 | |

| 10 | Lack of relationship between designers and contractors | 4.263 | 9 | 0.853 | |

| 11 | Waste prevention | 4.263 | 9 | 0.853 | |

| 12 | Capacity of contractor | 4.263 | 9 | 0.853 | |

| 13 | Economic status | 4.237 | 10 | 0.847 | |

| 14 | Climate | 4.211 | 11 | 0.842 | |

| 15 | Transportation | 4.184 | 12 | 0.837 | |

| 16 | Labor cost | 4.158 | 13 | 0.832 | |

| 17 | Equipment cost | 4.158 | 13 | 0.832 | |

| 18 | Cost of geosynthetic construction material | 4.079 | 14 | 0.816 | |

| 19 | Change in design | 4.079 | 14 | 0.816 | |

| 20 | Life-cycle cost | 4.053 | 15 | 0.811 | |

| 21 | Site distance/ proximity | 3.921 | 16 | 0.784 |

From the table above, it is clearly shown that the respondents’ perception on the factors affecting the selection and usage of geosynthetic materials for construction is the effect of weather since the material is to be exposed to weathering actions during its service years with a relative importance index of 0.947 and mean score of 4.74, followed by user’s/ owner’s choice of the material as the respondent’s purposes that the client has influence in deciding the usage with a relative importance index of 0.926 and mean score of 4.632, followed by the cost of geosynthetic material with a relative importance index of 0.921 and mean score of 4.605, followed by water resistance with a relative importance index of 0.889 and mean score average of 4.447 followed by the working experience of the designer/engineer with a relative importance index of 0.900 and mean score of 4.50 and the least ranked factor is site distance/ proximity.

4.6 Level of Relationship among stakeholders

Descriptive Statistics

| Mean | Std. Deviation | N | |

| Client | 4.63 | .819 | 76 |

| Designer | 4.50 | .507 | 76 |

| Contractor | 4.26 | .795 | 76 |

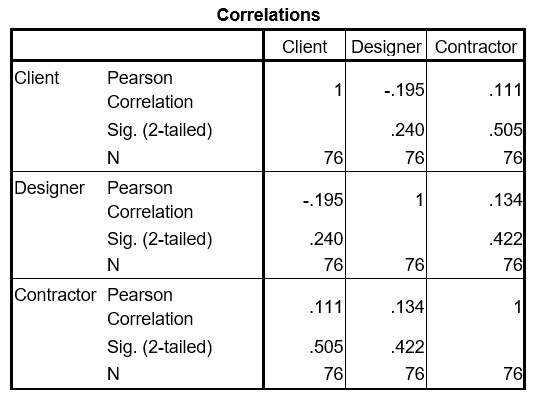

Table 4.10: the correlation between stakeholders

From the above table, there is no significance in the correlation i.e the value is higher than 0.05 of the confidence levels. The correlation between client and Designer is negatively correlated without significance (-1.95). The correlation between Designer and Contractor is 0.134 which is positively correlated without significance.

However, on the choice of geosynthetic materials by stakeholders, there is no existing relationship.

5. CONCLUSION AND RECOMMENDATION

5.1 Summary of Findings

The construction industry is faced with the great challenge of separation of design stage from construction stage and this has led to the lack of interrelationship between the major construction stakeholders on the decision to use geosynthetic materials in Nigeria for construction purposes. To this end, the major factor that encourages the use of geosynthetic material is as a result of its high strength followed by quality assurance and biodegradability. On the other hand, the factors responsible for the discouragement of the usage for construction purposes is as a result of effect of weather as ranked by the respondents followed by the client’s choice on the usage.

5.2 conclusion

Through the administration of a structured qualitative questionnaire and schematically analyzing the obtained data from the field, this research work has garnered examination to investigate the use of geosynthetic material, the factors influencing the use, the factors affecting the use and the relationship existing between the construction stakeholders in the use of geosynthetic materials for construction purposes.

This study concluded that most of the stakeholders are aware about geotextiles and geomembranes in that order and the most commonly used one is geotextile followed by geomembranes respectively.

The major factor influencing and encouraging the use of the mostly ranked geosynthetic material are high strength, quality control and assurance and biodegradability respectively.

More so, the major factors responsible for not using the material is weather and climatic condition.

5.3 Recommendation

As a result of this research findings, the following recommendations are made:

- The stakeholders concerned with the choice of construction materials for earth stabilization should give room for geosynthetic materials while at the design stage

- The geotextiles and geogrids have a life span of a hundred years which gives it a good strength and therefore, the professional bodies should encourage the use also.

- There should be a course that will treat this aspect of material at the university so as to acquaint young professionals to the material

- There should be an interpersonal relationship on the decision to use a construction material among the stakeholders in the construction industry.

5.4 Contribution to Knowledge

This research findings provides academic information on the level of use of the various geosynthetic materials, the responsible factors encouraging their usage, the despising factors discouraging the use by the construction stakeholders in Lagos-island.

5.5 Recommendation for Further Studies

This study focused mainly on assessing the use of geosynthetic materials by construction stakeholders in Lagos-island. As a result of its high strength and biodegradability properties, in conjunction with the high cost of importation of these materials, I would suggest a further study on how to create a locally made geotextile which will be a better source of income and source of internally generated revenue to the government.

REFERENCES

- Altun, S. T. (2012). Mechanical behaviour of sand-geotextile interface. Sharif University of Technology Transactions A: Civil Engineering, 1044–1051.