A hydraulic lift is a device that lifts things by applying force to a liquid inside a cylinder, which drives a piston higher. This Hydraulic Lift is used for carrying passengers or goods from one floor to another in a multi-storeyed building.

Fluid Systems

A fluid system is defined as a device in which power is transmitted with the help of a fluid which may be liquid (water or oil) or a gas (air) under pressure. Most of these devices are based on the principles of fluid statics and fluid kinematics. Following are the different devices that come under the Fluid systems.

- The hydraulic press

- The hydraulic accumulator

- The hydraulic intensifier

- The hydraulic Ram

- The hydraulic Lift

- The hydraulic Crane

- The fluid or hydraulic coupling

- The fluid or hydraulic torque converter

- The Air Lift pump

- The gear-wheel pump

Hydraulic Lift

A hydraulic lift is a device that lifts things by applying force to a liquid inside a cylinder, which drives a piston higher. This Hydraulic Lift is used for carrying passengers or goods from one floor to another in a multi-storeyed building.

The hydraulic lift principle is based on Pascal’s law for generating force or motion.

Pascal’s law in fluid mechanics states that a pressure change at any point in a confined incompressible fluid is transmitted throughout the fluid such that the same change occurs everywhere. This means that if you apply a force to a fluid in an enclosed container, the pressure will increase equally in all parts of the container and act at right angles to the walls.

Hydraulic lifts are of two types, namely,

- Direct-acting hydraulic lift

- Suspended hydraulic lift

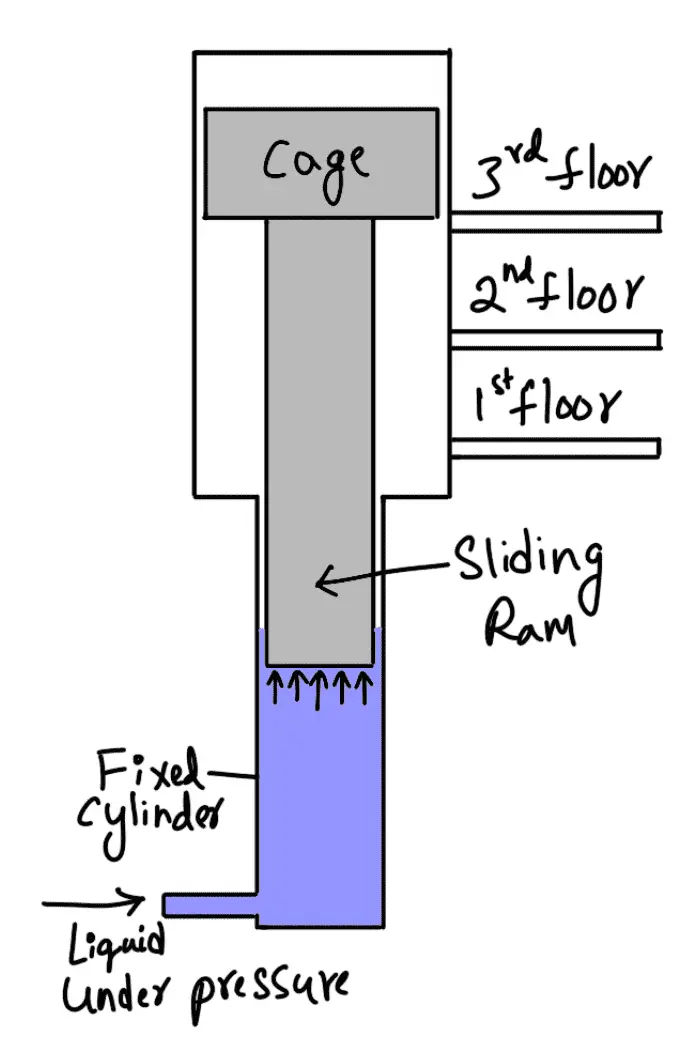

1. Direct Acting Hydraulic Lift

It consists of a ram, sliding in the fixed cylinder as shown in the following figure. At the top of the sliding ram, a cage (on which the persons may stand or goods may be placed) is fitted. The liquid under pressure flows into the fixed cylinder. This liquid exerts a force on the sliding ram, which moves vertically up and thus raises the cage to the required height.

The cage is moved in a downward direction, by removing the liquid from the fixed cylinder.

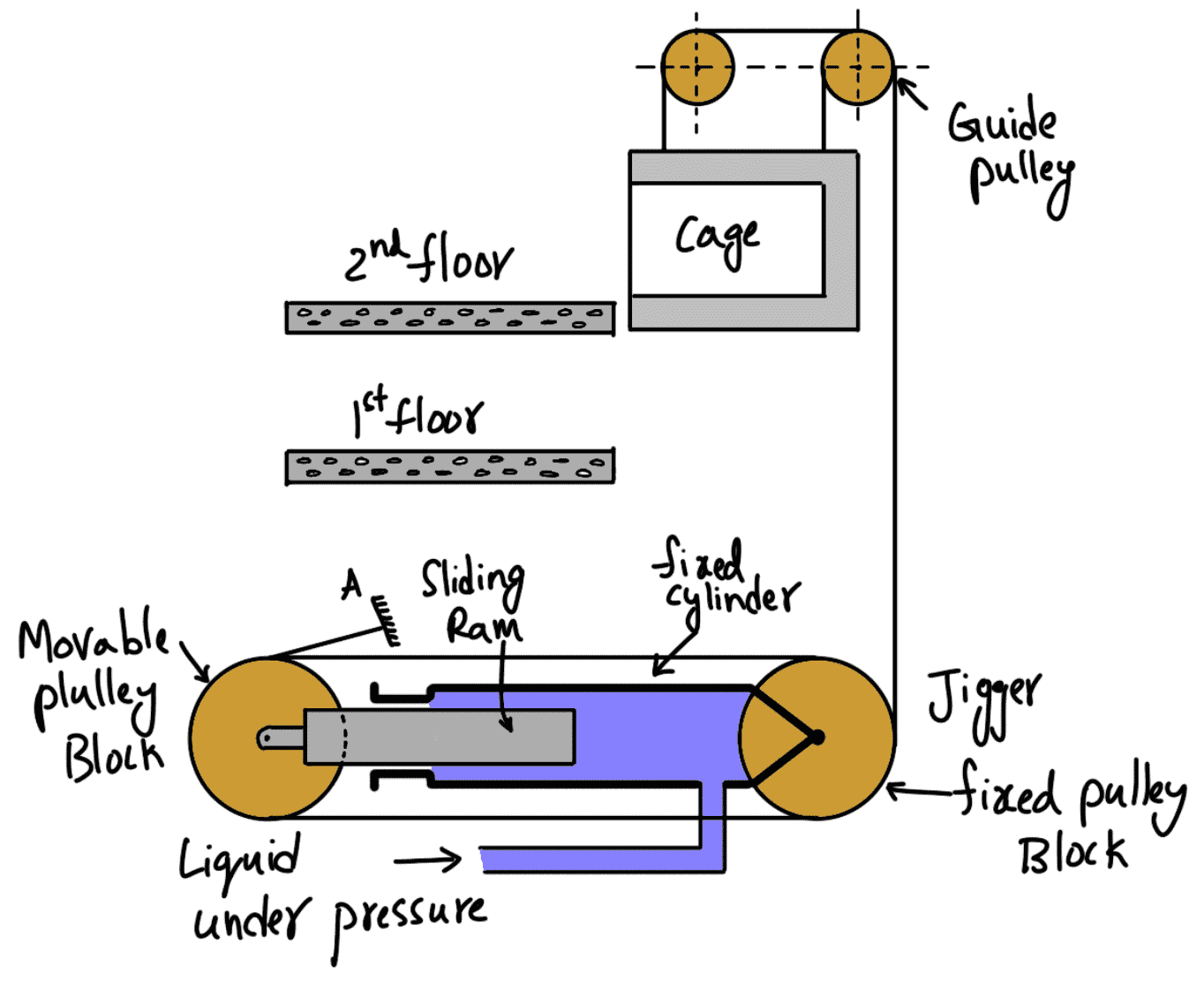

2. Suspended Hydraulic Lift

The following shows the suspended hydraulic lift. It is a modified form of the direct-acting hydraulic lift. It consists of a cage (on which persons may stand or goods may be placed) which is suspended from a wire rope. A jigger, consisting of a fixed cylinder, a sliding ram and a set of two pulley blocks, is provided at the foot of the hole of the cage. One of the pulley blocks is movable and the other is a fixed one. The end of the sliding ram is connected to the movable pulley block. A wire rope, one end of which is fixed at A and the other end is taken round all the pulleys of the movable and fixed blocks and finally over the guide pulleys as shown in The following figure. The cage is suspended from the other end of the rope. The raising or lowering of the cage of the lift is done by the jigger as explained below.

When water under high pressure is admitted into the fixed cylinder of the jigger, the sliding ram is forced to move towards the left. As one end of the sliding ram is connected to the movable pulley block and hence the movable pulley block moves towards the left, thus increasing the distance between the two pulley blocks. The wire rope connected to the cage is pulled and the cage is lifted. For lowering the cage, water from the fixed cylinder is taken out. The sliding ram moves towards the right and hence movable pulley blocks also move towards the right. This decreases the distance between two pulley blocks and the cage is lowered due to the increased length of the rope.

Advantages

- It is less expensive to install than other elevator types.

- It occupies less space in a building and does not require a separate machine room or overhead structural requirements.

- It is very effective with heavy loads because the hydraulic power provides great lifting strength.

Disadvantages

- It has a relatively slow lifting speed and cannot move faster than 150 feet per minute.

- It requires more ongoing maintenance and temperature control than other elevator systems.

- It can cause environmental problems if the hydraulic oil leaks out of the pumping system and contaminates the soil or groundwater.

- It can emit an unpleasant odour and make more noise than other elevator systems.

Example Problem on Hydraulic Lift

Problem Statement: A hydraulic lift is required to lift a load of 8 kN through a height of 10 metres, once every 80 seconds. The speed of the lift is 0.5 m per second. Calculate the Power required to drive the Hydraulic lift, the Working period of the lift in seconds, and the Idle period of the hydrauliclift in seconds.

Answer:

Given data

Load lifted, W = 8 kN = 8 × 1000 = 8000 N

Height, H= 10 m

Time for one operation, t = 80 s

Speedo f lift, v = 0.5 m/s

Work done in lifting the load in 80 seconds = W × H = 8000 × 10 = 80000 Nm

Work done/second = 80000 Nm / 80 sec = 1000 Nm/sec

Power required to drive the Hydraulic lift = (1/1000) × Work done/sec = (1/1000) × 1000 = 1 kW

Working period of the lift = Height of the lift / Velocity of lift = 10 / 0.50 = 20 seconds

Idle period of the lift = Total time – Working period of lift = 80 – 20 = 60 sec

This is all about the HydraulicLift and how we can calculate the Power required to drive a Hydraulic lift. Let us know what you think about this article in the comment section below.

Leave a Reply