The belts or ropes are used to transmit power from one shaft to another by means of pulleys that rotate at the same speed or at different speeds. The material used for belts and ropes must be strong, flexible, and durable. It must have a high coefficient of friction. There are 3 types of belts, Flat belts are one of them. Let us discuss the Types of Flat Belt Drives.

Types of Belts

Though there are many types of belts used these days, the following are important from the subject point of view:

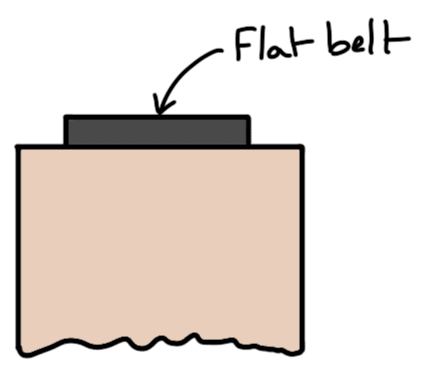

1. Flat belt

The flat belt as shown in the following figure is mostly used in factories and workshops, where a moderate amount of power is to be transmitted, from one pulley to another when the two pulleys are not more than 8 meters apart.

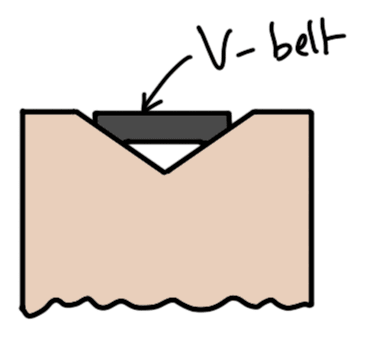

2. V-belt

The V-belt as shown in the following figure, is mostly used in factories and workshops, where a great amount of power is to be transmitted, from one pulley to another, when the two pulleys are very near to each other.

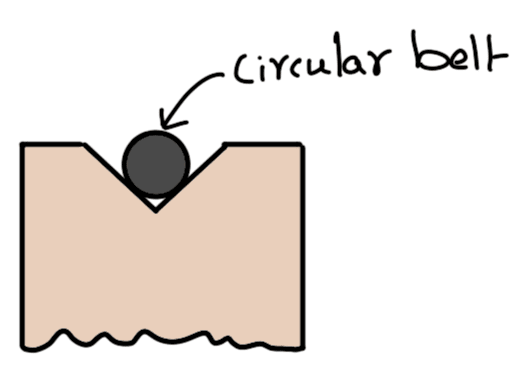

3. Circular belt or rope

The circular belt or rope as shown in the following figure is mostly used in factories and workshops, where a great amount of power is to be transmitted, from one pulley to another, when the two pulleys are more than 8 meters apart.

If a huge amount of power is to be transmitted, then a single belt may not be sufficient. In such a case, wide pulleys (for V-belts or circular belts) with a number of grooves are used. Then a belt in each groove is provided to transmit the required amount of power from one pulley to another.

Types of Flat Belt Drives

The power from one pulley to another may be transmitted by the following belt drive types.

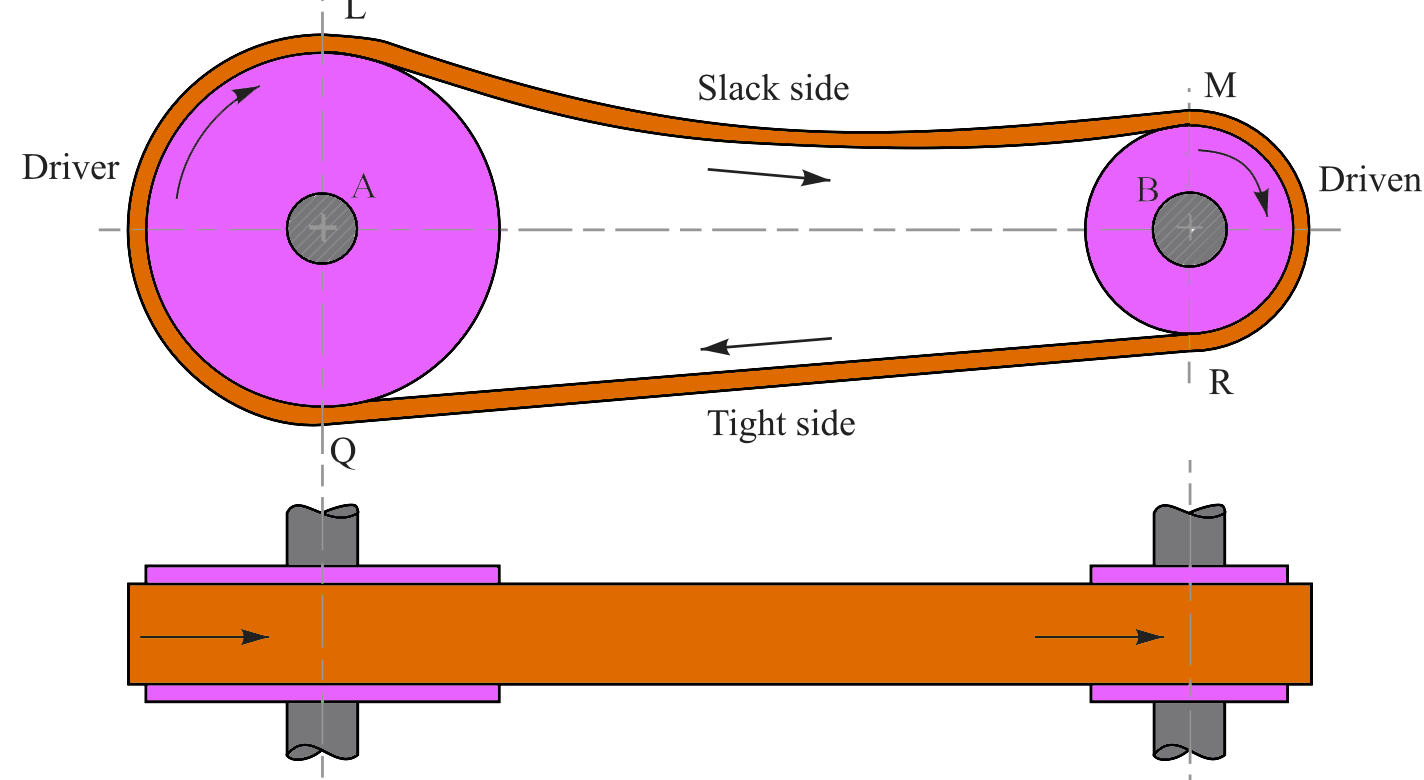

1. Open Belt Drive

The open belt drive is shown in the following figure. It is used with shafts arranged parallel and rotating in the same direction.

In this case, driver A pulls the belt from one side (i.e. lower side RQ) and delivers it to the other side (i.e. upper side LM). Thus the tension in the lower side belt will be more than that in the upper side belt. The lower side belt (because of more tension) is known as the tight side whereas the upper side belt (because of less tension) is known as the slack side, as shown in the above figure.

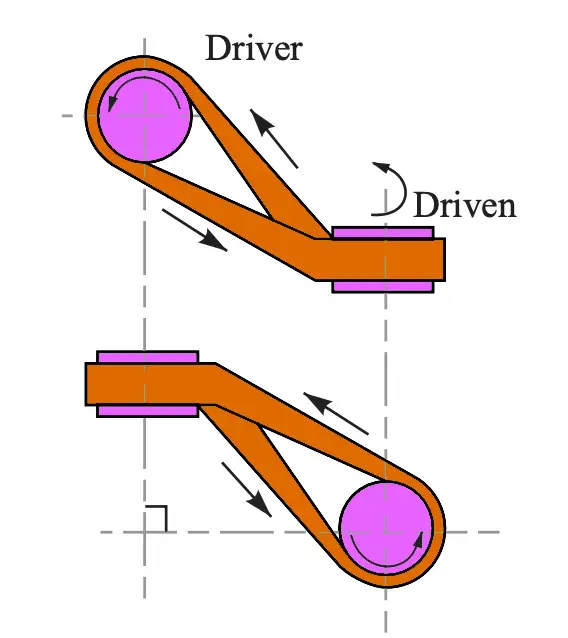

2. Crossed Or Twist Belt Drive

The crossed or twisted belt drive is shown in the following figure. It is used with shafts arranged parallel and rotating in opposite directions.

In this case, the driver pulls the belt from one side (i.e. RQ) and delivers it to the other side (i.e. LM). Thus, the tension in the belt RQ will be more than that in the belt LM. The belt RQ (because of more tension) is known as the tight side, whereas the belt LM (because of less tension) is known as the slack side, as shown in the above figure.

A little consideration will show that at a point where the belt crosses, it rubs against each other and there will be excessive wear and tear. In order to avoid this, the shafts should be placed at a maximum distance of 20 b, where b is the width of the belt and the speed of the belt should be less than 15 m/s.

3. Quarter Turn Belt Drive

The quarter-turn belt drive (also known as right angle belt drive) is shown in the following figure. It is used with shafts arranged at right angles and rotating in one definite direction.

In order to prevent the belt from leaving the pulley, the width of the face of the pulley should be greater or equal to 1.4 b, where b is the width of the belt.

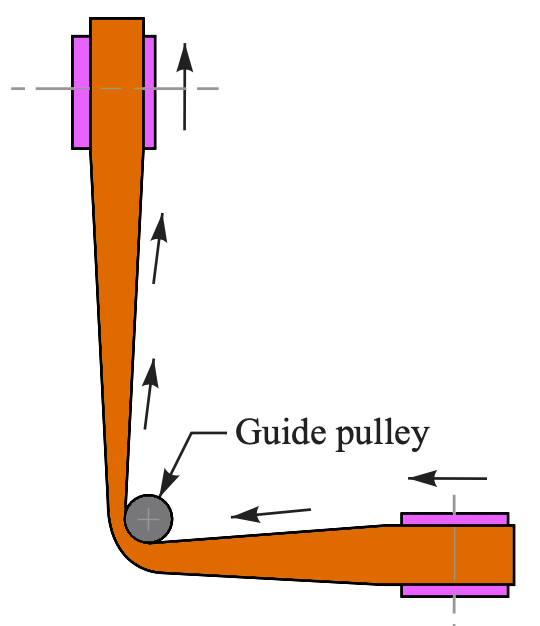

In case the pulleys cannot be arranged as shown in the above figure or when the reversible motion is desired, then a quarter-turn belt drive with a guide pulley, as shown in the following figure, may be used.

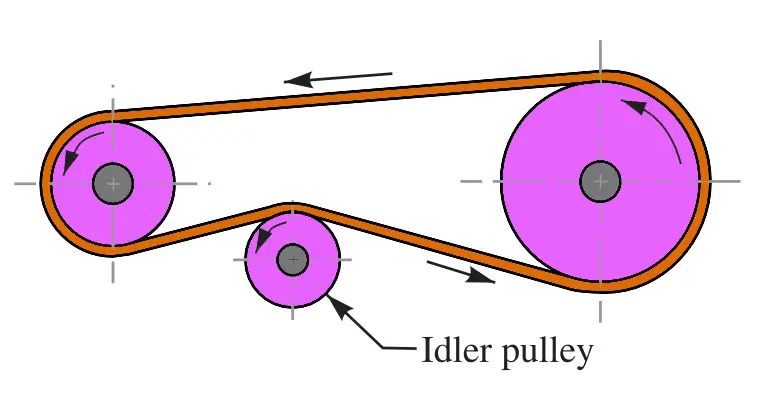

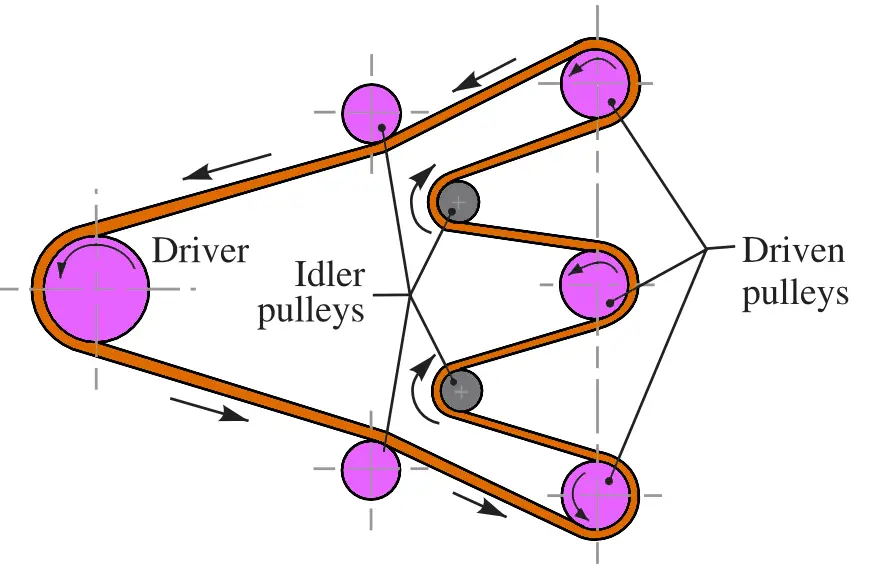

4. Belt Drive With Idler Pulleys

A belt drive with an idler pulley (also known as a jockey pulley drive) is shown in the following figure. It is used with shafts arranged parallel and when an open belt drive can not be used due to a small angle of contact on the smaller pulley.

This type of drive is provided to obtain a high-velocity ratio when the required belt tension can not be obtained by other means.

When it is desired to transmit motion from one shaft to several shafts, all arranged in parallel, a belt drive with many idler pulleys, as shown in the following figure, may be employed.

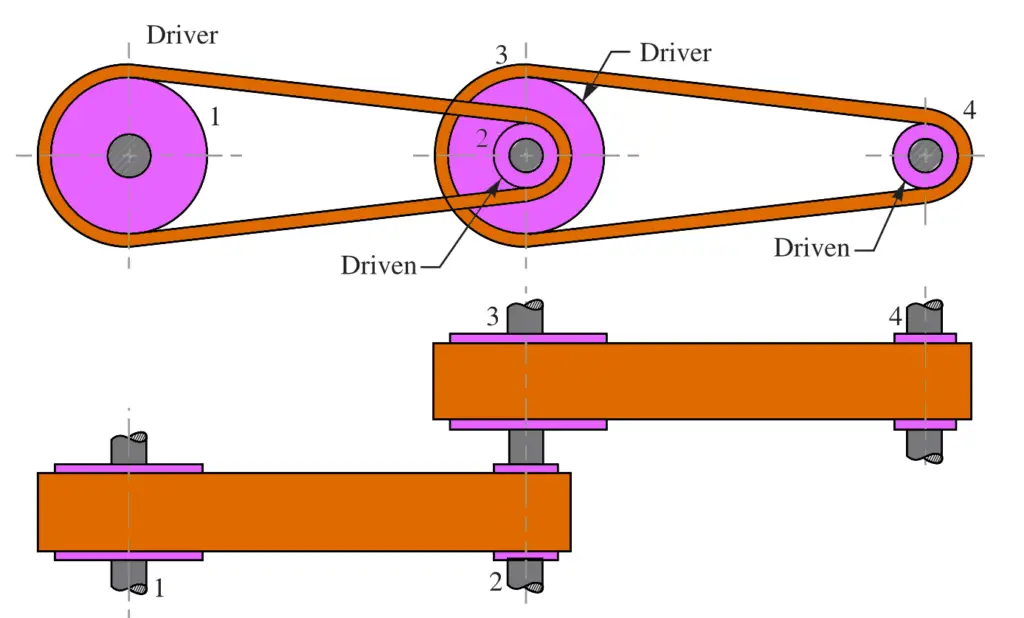

5. Compound Belt Drive

A compound belt drive is shown in the following figure. It is used when power is transmitted from one shaft to another through a number of pulleys.

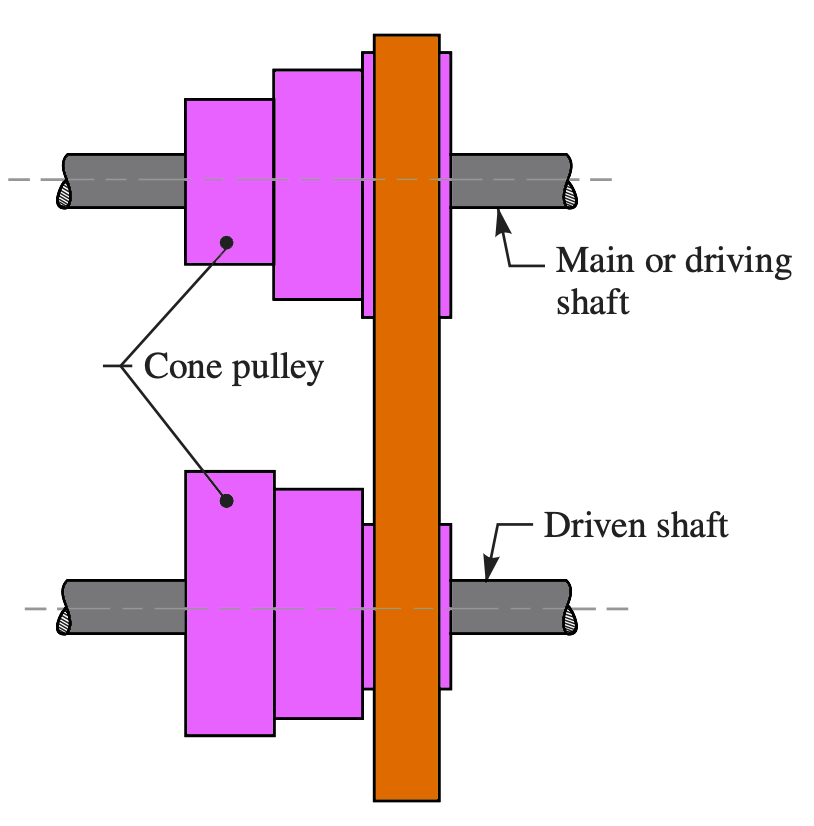

6. Stepped Or Cone Pulley Drive

A stepped or cone pulley drive, as shown in the following figure. It is used for changing the speed of the driven shaft while the main or driving shaft runs at a constant speed. This is accomplished by shifting the belt from one part of the steps to the other.

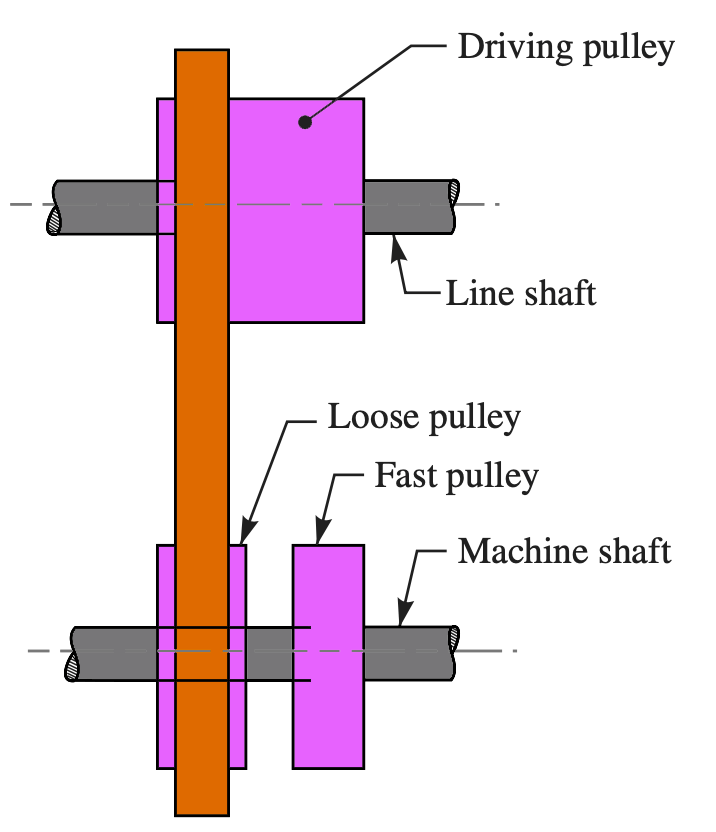

7. Fast And Loose Pulley Drive

A fast and loose pulley drive, as shown in the following figure. It is used when the driven or machine shaft is to be started or stopped whenever desired without interfering with the driving shaft.

A pulley that is keyed to the machine shaft is called a fast pulley and runs at the same speed as that of the machine shaft. A loose pulley runs freely over the machine shaft and is incapable of transmitting any power. When the driven shaft is required to be stopped, the belt is pushed onto the loose pulley by means of the sliding bar having belt forks.

These are the different types of flat belt drives that we have. Have you encountered anything other than what we mentioned here? Let us know what you think about these different types of flat belt drives in the comment section below.

Leave a Reply