What is a Rivet? Well, A Rivet is a permanent fastening element mostly used for fastening light metals of plates in Boiler shells, structural works, Shipbuilding, and bridges. In the previous article, we have discussed the Riveted joint method, Different Rivethead types, and the materials used for the Rivets according to the Indian Standards. In this article, we are going to discuss the different types of Riveted Joints.

Types of Riveted Joints based on the Plates Arrangement

Primarily, based on the plates arrangements which needed to be joined, the Riveted joints can be classified as

- Lap Joint

- Butt Joint

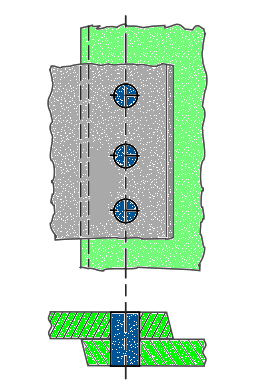

1. Lap Joint

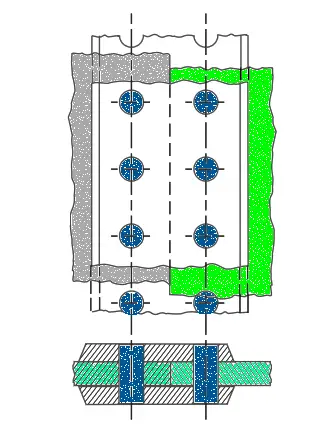

As shown in the above schematic arrangement of the two plates one over the other to join them together with a Rivet is called the Lap Joint.

2. Butt Joint

As shown above, in the Butt joint the main plates are kept in alignment butting each other and the cover plates are placed on both sides or one side. The cover plates are riveted together with the main plates to make the joint.

The butt joint can be further classified into following

(a) Single strap butt joint

(b) Double strap butt joint

(a) Single strap butt joint

The above figure is the schematic arrangement of the single strap butt joint. In this single strap butt joint, the edges of the main plates butt against each other and only one cover plate is placed on one side of the main plates and then riveted together as shown in the above figure.

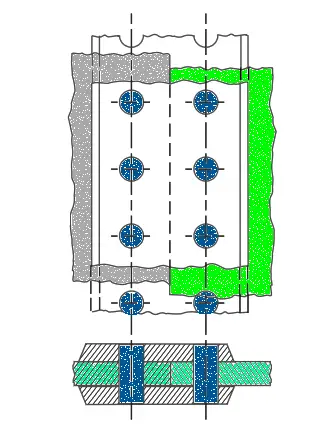

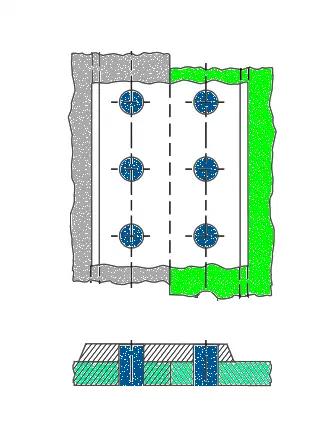

(b) Double strap butt joint

The above figure is the schematic arrangement of the Double strap butt joint. In this double strap butt joint, the edges of the main plates butt against each other and two cover plates are placed on both sides of the main plates and then riveted together as shown in the above figure.

Types of Riveted Joints based on Number of rows of the Rivets

Secondarily, based on the number of rows of the rivets on the joint, the following are the classification of Riveted Joints

- Single riveted joint

- Double riveted joint with chain arrangement

- Double riveted joint with zig-zag arrangement

With this rivet arrangement, we can make these Rivet arrangements for the Lap joint or for Butt joints.

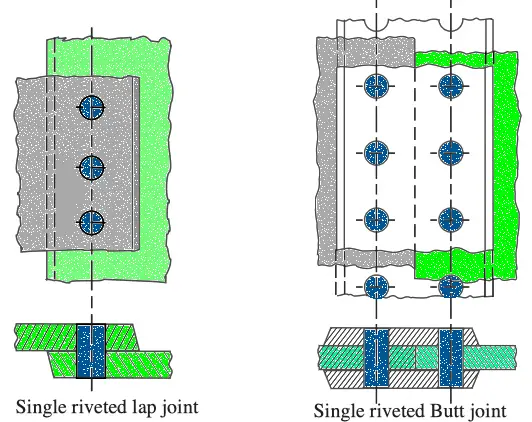

1. Single riveted joint

As shown in the above figure, the schematic arrangement of the single row of Rivets on the lap joint and the butt joint. In this single Riveted Joint, for the lap joint (left side figure), there is only one row of the rivets, and for the butt joint (right side figure) there is a single row of rivets on each side of the butt joint.

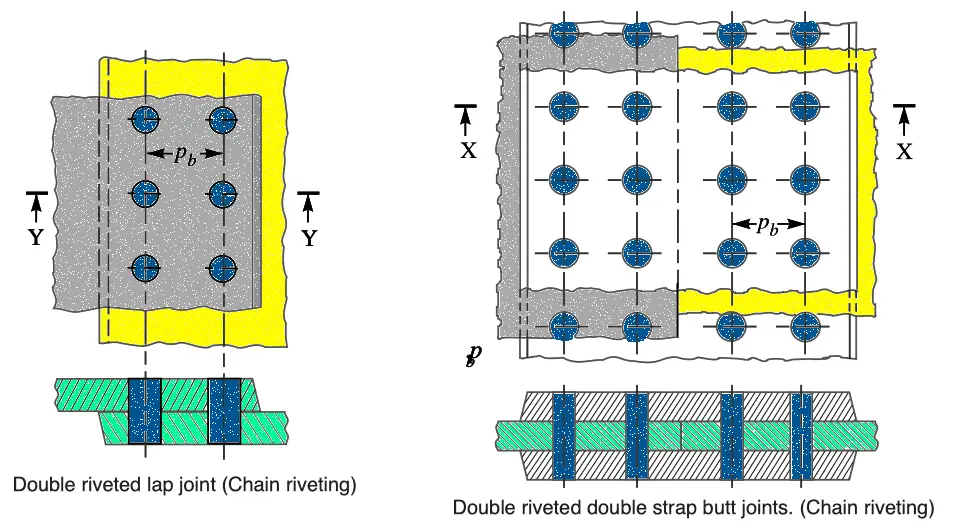

2. Double riveted joint with chain arrangement

As shown in the above figure, the schematic arrangement of the double row of Rivets with chain riveting on the lap joint and the butt joint.

In this double riveted joint with the chain arrangement of the rivets, there are two rows of rivets, which are arranged opposite to each other as shown above in the lap joint(left side figure).

For the butt joint(right side figure) the arrangement of rivets will be on either side.

The arrangement of the rivets opposite to each other is called the Chain Riveted.

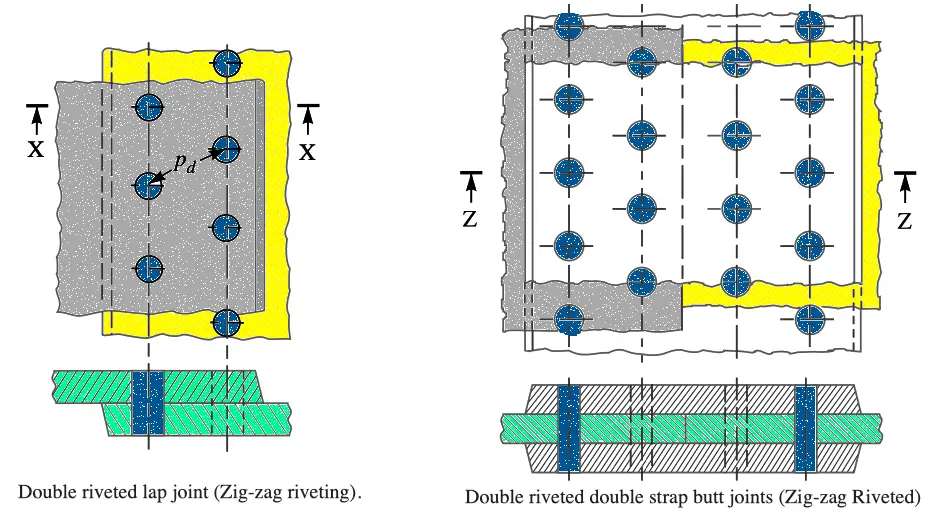

3. Double riveted joint with zig-zag arrangement

As shown in the above figure, the schematic arrangement of the double row of Rivets with Zig-zag riveting on the lap joint and the butt joint.

In this double riveted joint with the zig-zag arrangement of the rivets, there are two rows of rivets, which are staggered in such a way every rivet is in the middle of the two rivets of the opposite row as shown above in the lap joint(left side figure).

For the butt joint(right side figure) the arrangement of rivets will be on either side.

The arrangement of the rivets staggered in such a way every rivet is in the middle of the two rivets of the opposite row is called the Zig-zag Riveted.

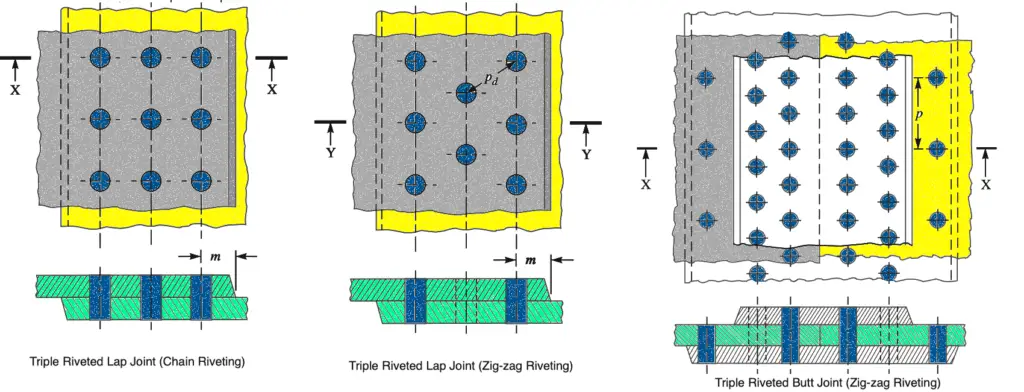

similarly, as like double riveted joints, there triple-riveted or quadruple riveted upon the necessary applications.

Triple Riveted Joints

Following are the triple-riveted Joints with chain arrangement and the zig-zag arrangement in both Lap joint and the Butt joint.

These are all the different types of Riveted Joints based on the Plate arrangement and the number of rows of rivets.

Along with this, we have a few terminologies we need to understand while we work with Riveting. Those are

Pitch: It is the distance from the centre of one rivet to the centre of the next rivet measured parallel to the seam as shown in the above figure. It is usually denoted by p.

Back pitch: It is the perpendicular distance between the centre lines of the successive rows as shown in the Double riveted joint with a chain arrangement diagram. It is usually denoted by pb.

Diagonal pitch: It is the distance between the centres of the rivets in adjacent rows of zig-zag riveted joint as shown in the above figure. It is usually denoted by pd.

Marginal pitch: It is the distance between the centre of the rivet hole to the nearest edge of the plate as shown in the above figure. It is usually denoted by m.

To make these riveting joints leak-proof, we need to do the process called Caulking and Fullering.

Conclusion

There are different types of Riveted Joints according to the plate arrangement, and the number of rows of rivets arrangements, which are discussed with the schematic arrangement diagrams above. Please let us know what do you think about them in the comment section below.

The way they explain rivets in diagram. Which very good approach to client and explain them in very innovative way.

I feel enriched by reading your informative post. You’re indeed a beacon of knowledge in this subject.