We have been seeing the shafts with the different cross-sections. What would really happen when a mechanical component has a different cross-section? Would it affect the stress distribution in the component? Yes exactly. Let’s see how the irregular stress distribution results in stress concentration.

Stress Concentration

Stress concentration occurs due to the irregular stress distribution. This irregular stress distribution occurs due to the different cross-sections, the presence of sharp corners, sharp edges, notches or holes, keyways, scratches.

Let’s see how the stress distribution differs in the different cross-section.

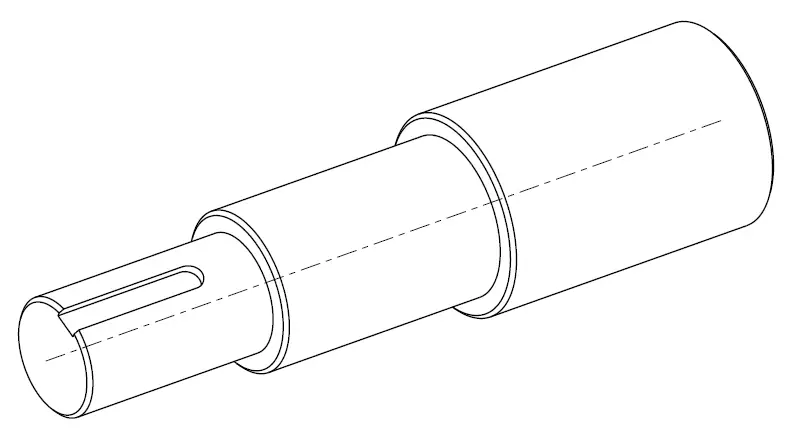

- Every mechanical component is made up of different cross-sections. For example, consider a shaft with different cross sections as shown in the figure.

- Now, this shaft is subjected to the tensile load or the twisting load, consider tensile load.

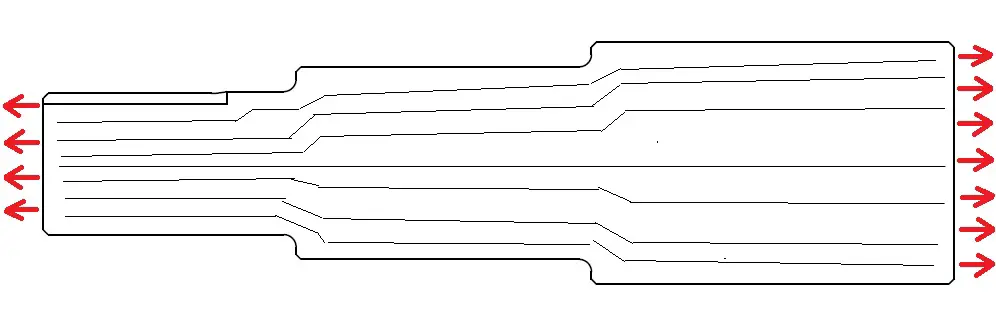

- The stress distribution in the differential cross section will be different in the form of stress flow lines as shown in the figure.

- The region where the cross section changing has more irregular stress distribution as shown with the stress flow lines shown above.

- This will result in more stress concentration at the irregular stress flow lines than the average value throughout the body.

- That cause fractures or failure of the component due to more stress concentration at one point.

How to reduce the Stress concentration?

Well, let’s say a sharp edge is experiencing the high-stress concentration, so we can reduce the stress by providing the fillet. As the fillet radius increase, the connection area will also increase results in a reduction in the concentration of stress at these edges.

This phenomenon occurs for all kind of stress in the presence of the sharp corners, sharp edges, smaller fillets at the edges, notches, holes, keyway, splines, and scratches. but all these will not be solved by simply providing the fillet. There are different methods available to reduce the concentration of stress.

Methods of Reducing Stress Concentration are discussed here!

Leave a Reply