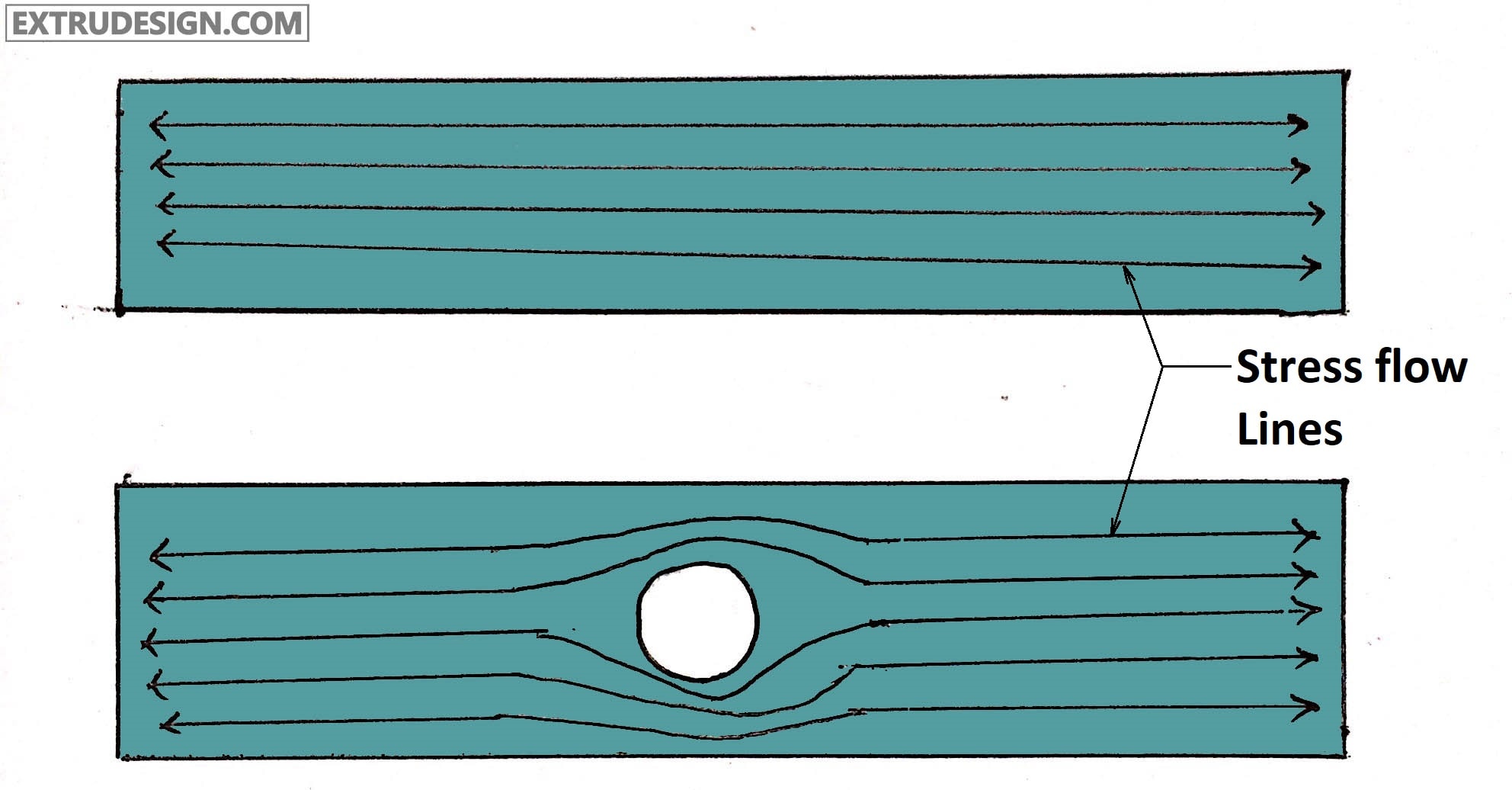

What exactly the notch sensitivity means? From our previous article, we have discussed how a fillet or a notch or a hole can reduce the stress concentration. But in this case, it will look somewhat different. actually, due to the presence of the notch or a hole in the body, the body tends to have non-uniform stress flow lines. In this cases, these notches or holes cause the more stress concentration. Doesn’t make sense to you? let’s understand it in a clear way.

Notch Sensitivity

By definition, Notch Sensitivity is the sensitivity of the material to the developing notches Under cyclic/fluctuating loading due to the stress concentration, geometric discontinuity, and it also depends on the hardness of the material.

Make sense?

See the following example.

In the above two bodies, one is having the straight stress flow lines and the second body having a hole at the centre of the body which causes the non-uniform stress flow lines.

So that the body which is having straight stress flow lines can withstand more load than the body which is having non-uniform stress flow lines.

as you can see the following example here when we apply a load on both bodies. The body with a hole at the centre is failed quickly due to stress concentration than the body with the straight stress flow lines.

Here the notch sensitivity also depends on the material property.

- so as the material is brittle then there will be more notch sensitivity (Can quickly getting notches due to the cyclic loading or impact loading).

- As the material is Ductile, the notch sensitivity is less (not so quick in getting the notches due to the cyclic loading or impact loading).

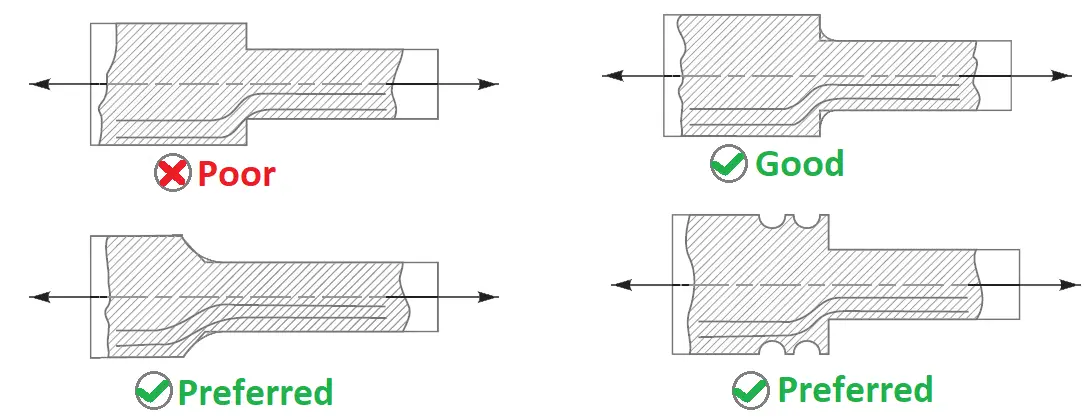

But as we dissed a fillet or a notch or a groove can reduce the stress concentration? how is that possible?

Yes. it is. In the above case, we are talking about the notch which generated by the cyclic loading called as a fracture. But in the case, we provide such a notch or hole or fillet to make the stress flow lines more smooth as shown in the below pictures. Have a look at the different cross-section as shown in the following images

as the more fillet radius or a grooved around the cylinder are more likely to reduce the stress concentration at the change in section.

So please read the full article on how to reduce the stress concentration here!

back to the subject

So how we can find out the notch sensitivity.

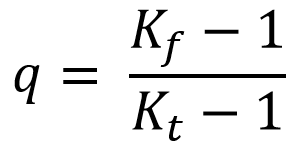

well, we have a formula that.

From the above relation, we can find the notch sensitivity(q)

where

Kf = Fatigue stress concentration factor.

Kt = Theoretical stress concentration factor.

Conclusion

We have discussed the notch sensitivity and how it is different from the other notch which is given for reducing the stress concentration. Still, have any questions? please let us know in the below comments.

Good content.. But still having a doubt whether a notch increases or decreases stress concentration

A notch or a groove or a fillet will be helpful for the shafts with a different section. But it will increase the chance of fracture in the case of a flat body. see both examples above.

What zero notch sensitivity signifies ?

Low notch sensitivity is usually associated with ductile materials.

Hello. What is the engineering definition of “notch” that is used here

Regards,

Tom