In metal works, Milling is a machining process which is performed with a rotary cutter with several cutting edges arranged on the periphery of the cutter. It is a multiple point cutting tool which is used in conjunction with a milling machine. This process is used to generate flat surfaces or curved profiles and many other intricate shapes with great accuracy and having a very good surface finish. Milling machines are one of the essential machines in any modern machine shop.

Basic Milling Operation

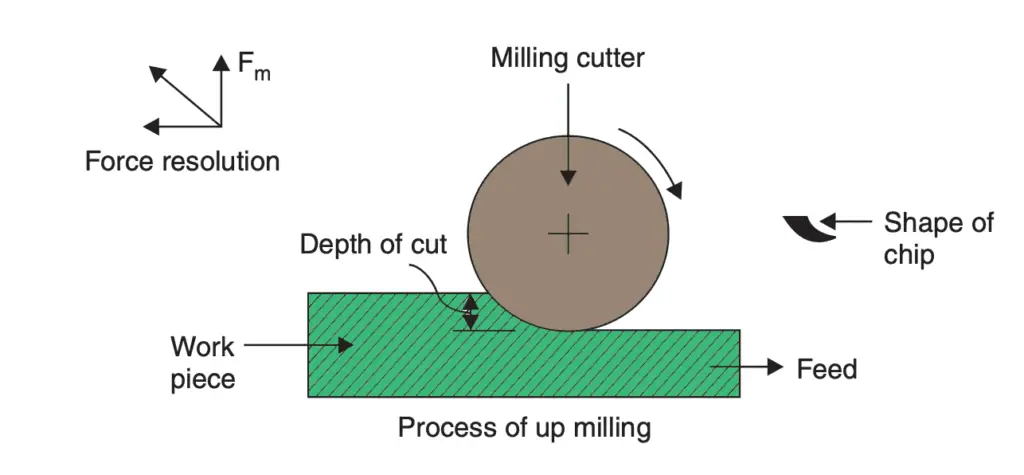

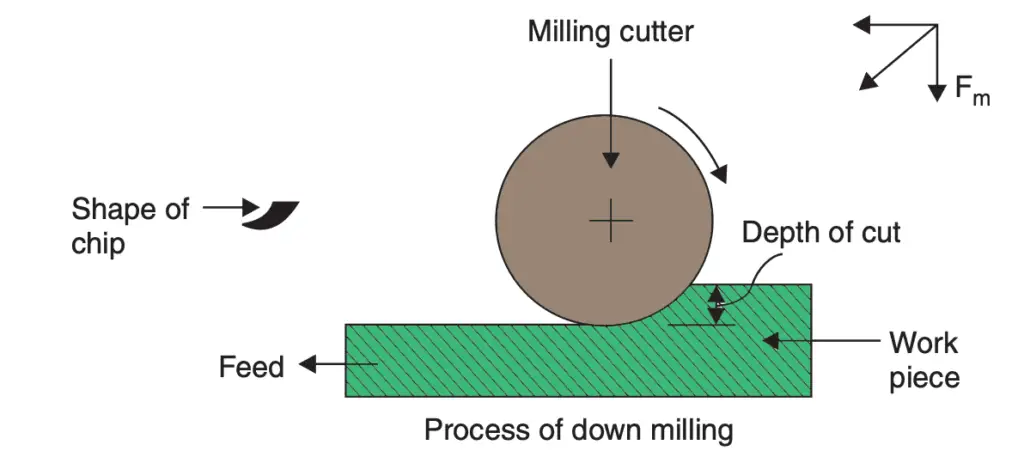

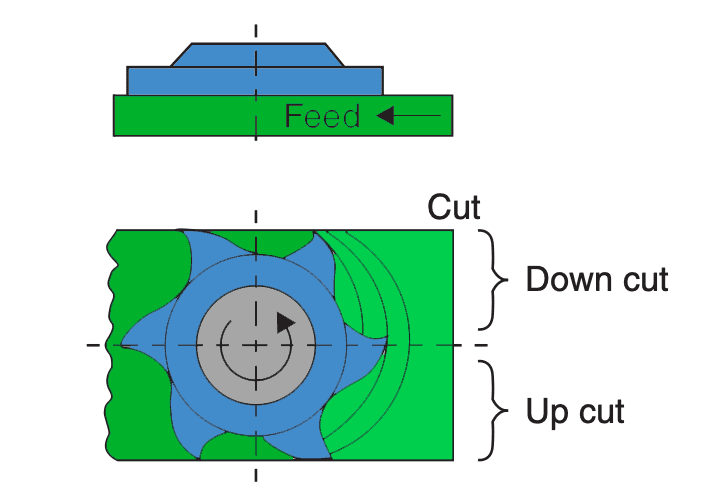

Generally, there are two types of milling processes. These are called

- Up milling or conventional milling process

- Down milling or climb milling process

Both these processes are illustrated below with schematic diagrams individually.

- In up milling, the direction of rotation of the milling cutter and the direction of workpiece feed are opposite to each other.

- Whereas in down milling, they move in the same direction at the point of contact of the cutter and the workpiece.

- In up milling, the thickness of the chip at the start is nil and is maximum when the cutting teeth leave the surface of the workpiece. In down milling, it is vice-versa.

- In up milling, the cutting teeth try to uproot and lift the workpiece from the machine table, in down milling, the reverse happens.

- Technically, down milling is a superior process, but up milling is commonly used.

- Down milling is not used unless the milling machine is fitted with a backlash eliminator.

- From the above figures, basic milling operation can also be understood.

- The milling cutter is circular and a large number of cutting edges (or teeth) are arranged along its circumference.

The cutter is rotated at a speed of N in r.p.m.

If the cutter diameter is D, then

The *cutting speed at the tip of the teeth = π×D×N metres/minute.

*It should conform to the recommended values.

- The depth of cut is clearly shown in the figure and the thickness of the workpiece will reduce by this amount in one pass.

- Usually, the width of the milling cutter is more than the width of the workpiece, hence one pass is all that is required.

- The feed of the workpiece is measured in terms of mm/minute.

- Actually, the correct measure of feed is the movement of workpiece per revolution of cutter per teeth.

If a milling cutter has z number of teeth

If the table feed is ‘f’ mm/minute

The feed per revolution per teeth = f/NZ mm.

Note: It should therefore be clear that the metal removal rate in milling operations is much higher than in shaping or planning operations

However, as in shaping or planning operation, the stroke length is always a little more than the length of the job, in milling operation also, the minimum table traverse required is L + D, where L is the length of the job and D is the milling cutter diameter. D/2 is the minimum overlap required on either side of the job so that the cutter becomes clear of the job.

Unlike turning, the milling process involves intermittent cutting and the chip cross-section is not uniform. The high impact loads at entry as well as fluctuating cutting force make the milling process subject to vibration and chatter. This aspect has a great influence on the design of milling cutters.

Types Of Milling Processes

The milling process is broadly classified as follows.

- Peripheral milling

- Face milling

- End Milling

In peripheral milling, the cutting edges are primarily on the circumference or periphery of the milling cutter and the milled surface is generally parallel to the cutter axis.

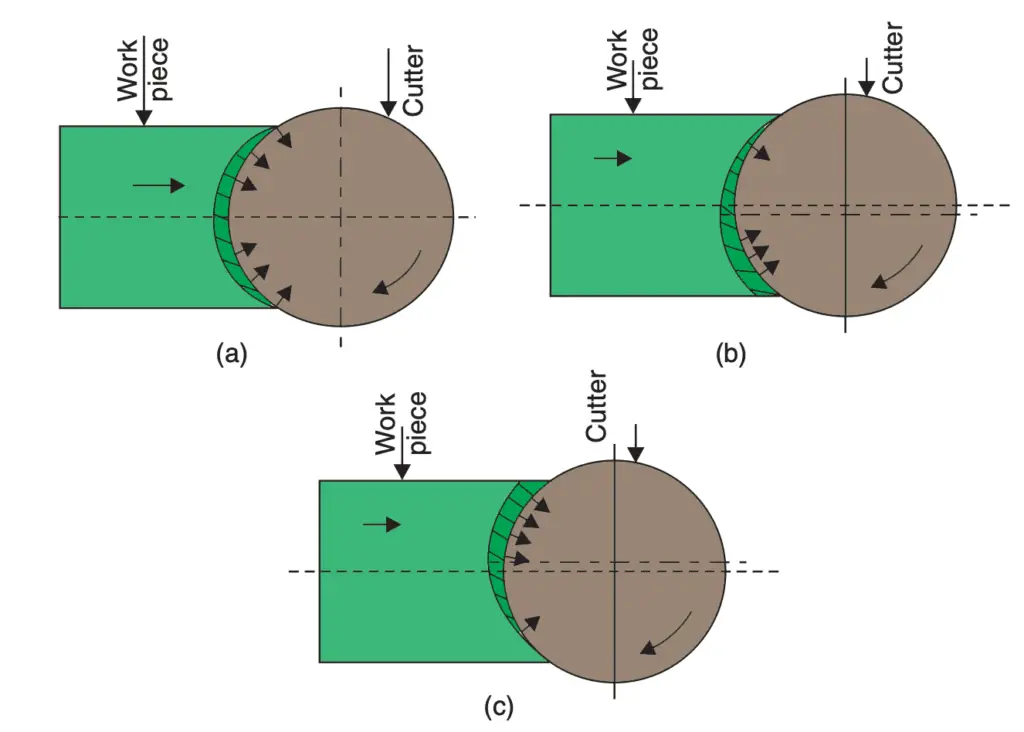

In face milling, although the cutting edges are provided on the face as well as the periphery of the cutter, the surface generated is parallel to the face of the cutter and is perpendicular to the cutter axis. In the following figure, both these processes have been illustrated.

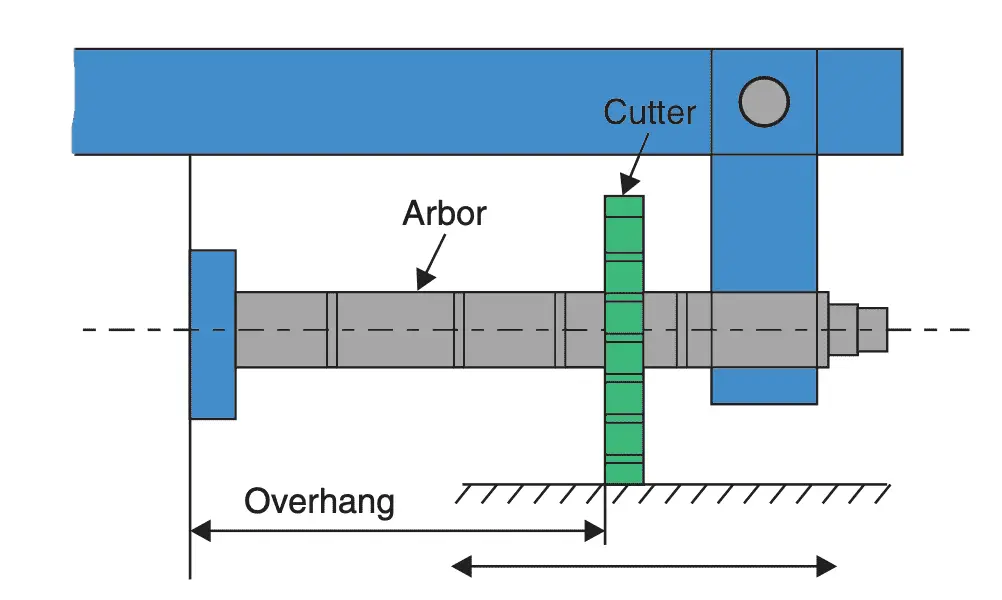

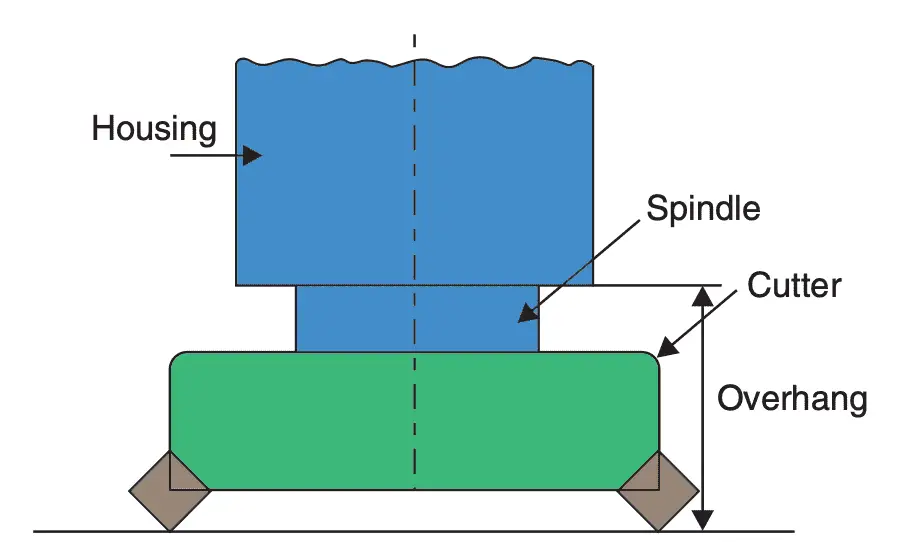

The peripheral milling cutters are supported on a long arbour. The deflection of the arbour restricts the dimensional and form accuracy of this process. In face milling, the overhang of the cutter is limited resulting in better dimensional control and flatness. Peripheral milling cutters are normally used with a horizontal milling machine whereas the face cutters are used in conjunction with a vertical milling machine.

Milling cutters are made of solid high-speed steel or have high-speed steel inserts. The cutters are also made, with tungsten carbide blades (either brazed or with throw away inserts).

1. Peripheral Milling

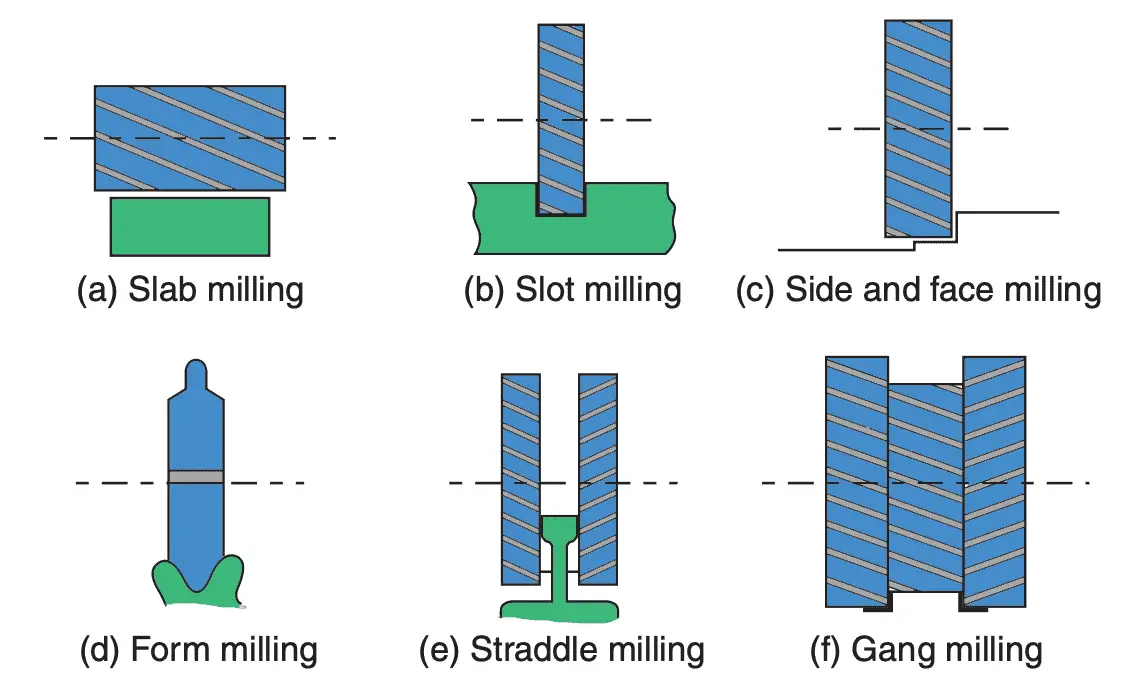

Peripheral milling is adopted for the following machining operations:

- Slab milling to produce flat surfaces.

- Slot milling to produce precision slots.

- Side and face milling to machine adjacent horizontal and vertical surfaces simultaneously.

- Form milling to produce the prismatic shape of any form, e.g., involute form in gear cutting.

- Straddle milling to machine two parallel vertical faces.

- Gang milling to machine a number of surfaces simultaneously with a set of cutters.

The various peripheral milling operations are illustrated in the following figure.

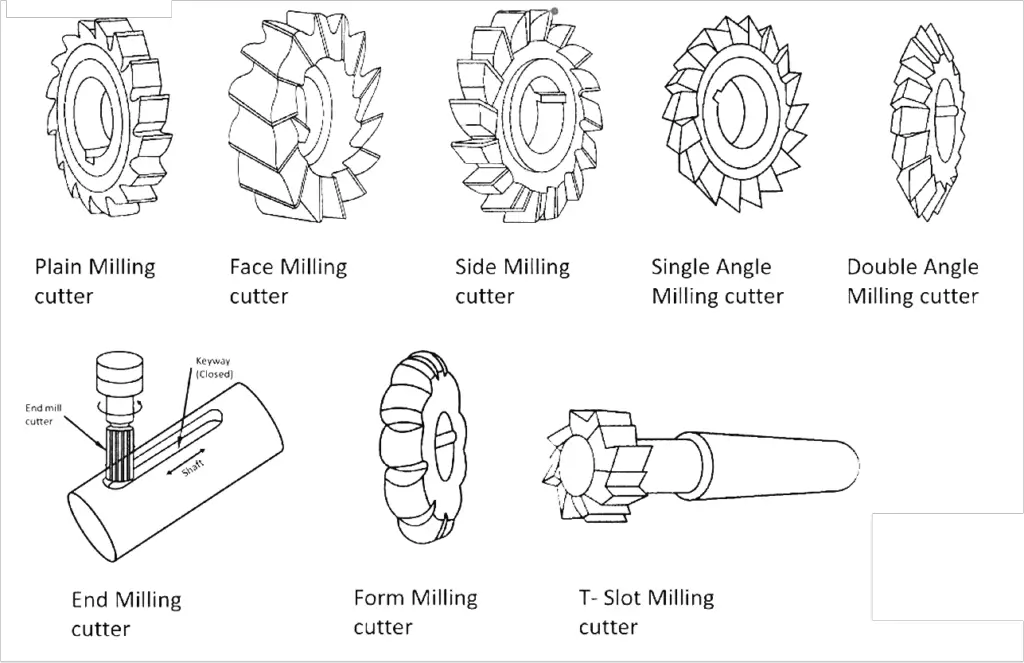

A number of milling cutters of peripheral milling type are shown in the following figure. The hole and the keyway provided in the centre of all peripheral cutters is for mounting them on the arbour of a horizontal milling machine.

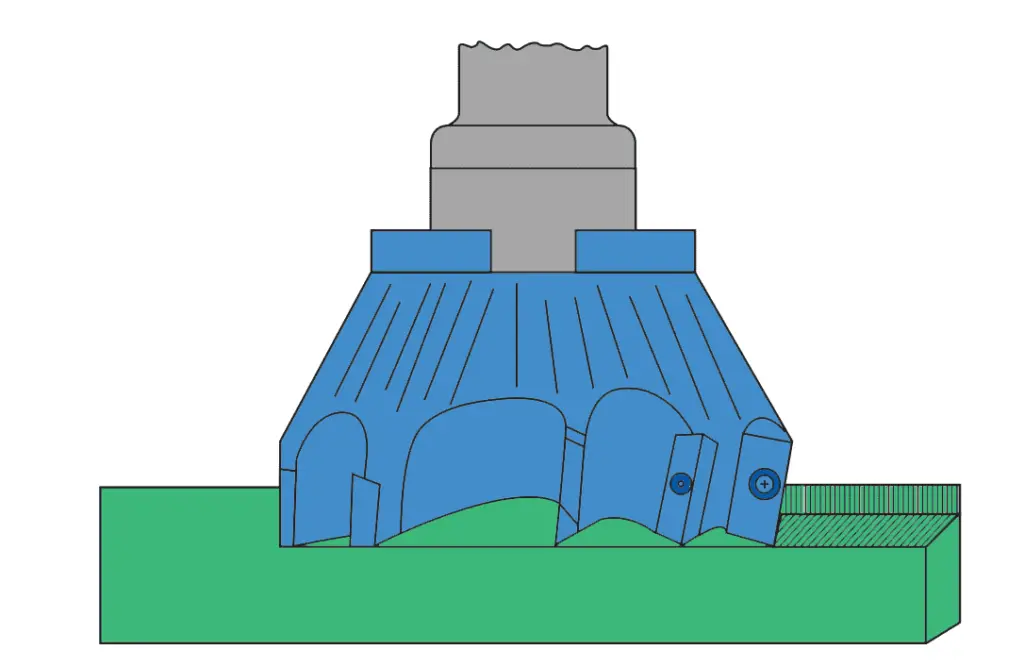

2. Face Milling

Face milling is widely used for milling operations involving a high metal removal rate. The operation of face milling with a face milling cutter having coated tungsten carbide inserts is shown in the following figure.

Face milling is a combination of up cut and down cut milling operations. The points discussed earlier regarding up and down milling operations in peripheral milling, apply equally well to the face milling operation as shown in the following figure.

In face milling, the position of the cutter with respect to the workpiece is of considerable significance. Three possibilities are there. Either the cutter may be symmetrically placed on the workpiece or it may be asymmetrically placed, offset slightly towards the entry side or it may be asymmetric, offset slightly towards the exit side. All three positions are shown in the following figure.

Asymmetric milling with larger chip thickness at entry and smaller chip thickness at the exit as shown in the above Figure (b) is ideal and should be adopted.

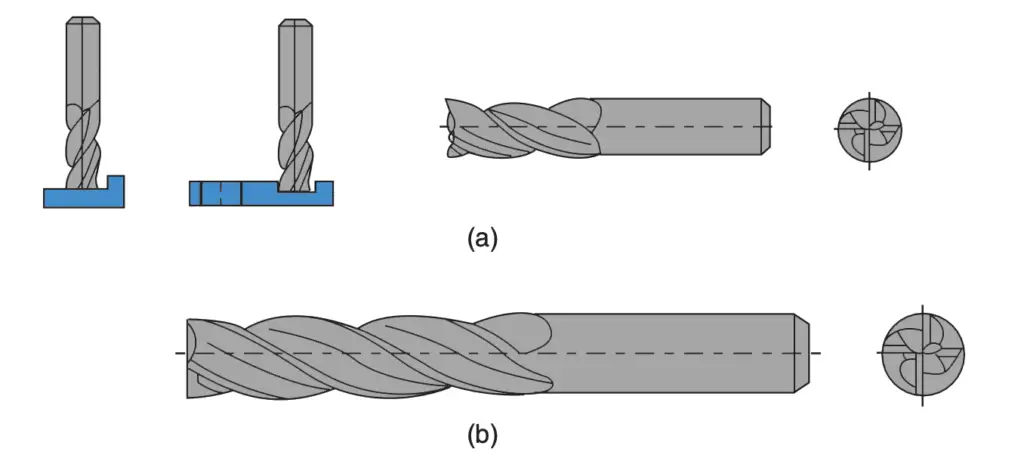

3. End Milling

End mills perform a combination of peripheral as well as face milling operations simultaneously. It has got cutting edges on the bottom face as well as on its periphery. End mills are extremely useful and are used for machining edges, shoulders, grooves, slots and keyway pockets. They are also widely used for die-sinking and the generation of sculpted surfaces.

Today, end mills are available in many tool materials:

- Cobalt high-speed steel (super H.S.S.)

- Coated H.S.S.

- Solid carbide

- Micrograin solid carbide

- Indexable inserts of cemented carbide or coated carbide.

A solid carbide end mill and its applications in shoulder and pocket machining are shown in the following figure. End mills have a tapered shank which fits into a tapered sleeve provided in the spindle of a vertical milling machine.

(a) short series

(b) long series

Different Types of Milling Machines

All the milling cutters described above are used in conjunction with milling machines, which provide the rotary movement to the cutters and feed to the workpiece and arrangement for clamping, automatic feed etc. Milling machines come in three basic models:

- Horizontal milling machines,

- Vertical milling machines, and

- Universal milling machines (This is also of horizontal type with a few special features).

Other configurations of the milling machine have been developed for special applications, but the above three are the most common.

1. Horizontal Milling Machine

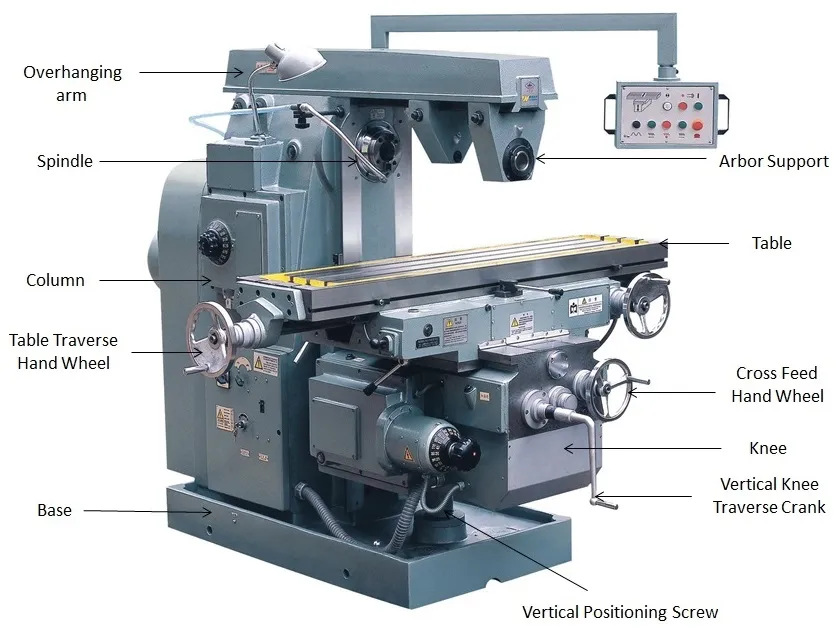

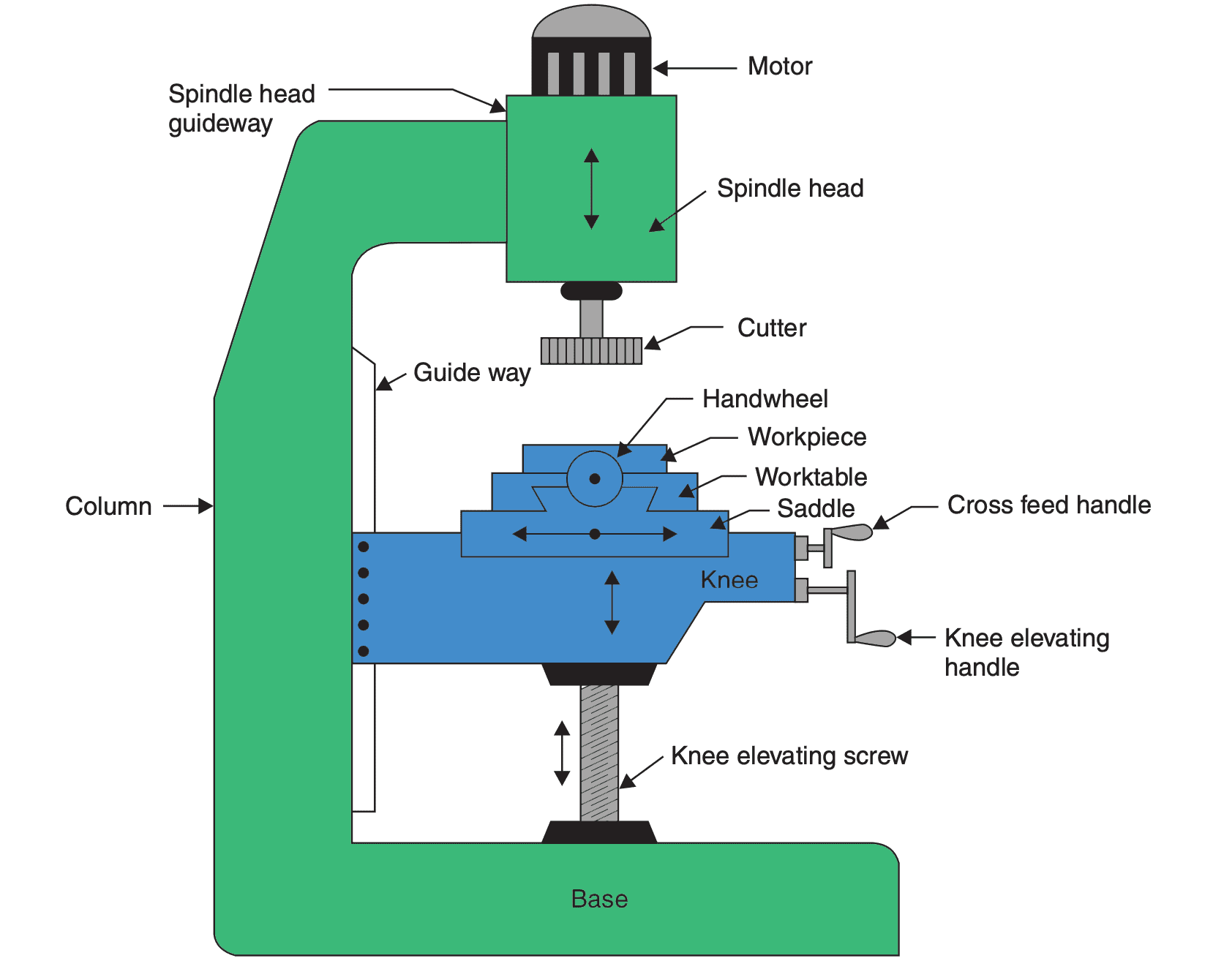

The most common type of milling machine is the horizontal knee-type; so-called, because of the overhanging ‘‘knee’’ which can slide up and down the front of the machine and which carries the cross slide and the table. A diagram of the horizontal milling machine is given in the following figure.

Horizontal milling machines may be either plain or universal types. The main difference between the two is that the table of the universal type is mounted on a turntable and maybe swivelled in a horizontal plane. This feature permits the cutting of the helix.

In addition, the standard accessories provided on the universal machine include a ‘dividing head’ for indexing. There are some other minor refinements, which make the universal horizontal machine very useful for tool room work.

The plain version of the horizontal machine is much more robust and more suitable for production work. In the diagram, the arbour on which peripheral cutters are mounted is not shown. It is fitted in the spindle nose ‘C’ and extends a little beyond arbour supporting bracket ‘B’.

Even end mills, face milling cutters and drills etc. can be used with this machine. In such a situation, the arbour is removed and the taper shank of these cutters is fitted into the hollow spindle ‘C’. With such an arrangement the vertical faces of the workpiece may be milled without any difficulty.

The table of the horizontal milling machine can be given either hand feed or auto-feed. It is also capable of being traversed at high speed. With these features, the machine proves really useful.

2. Vertical Milling Machine

The application and technique of this machine differ from that of a horizontal milling machine. It does not have an arbour and instead has a vertical spindle into which the taper shank of end mills and facing milling cutters and drills etc. can be fitted. The arrangement and movement of the table are similar to the table of a horizontal milling machine.

This machine is used for making, flat surfaces, grooves, slots, pockets and guideways etc. in workpieces using end mills and facing mills etc.

3. Universal Milling Machine

As we mentioned above that the Universal Milling Machine is also of horizontal type with a few special features. Its features have already been described under the heading of horizontal milling machine.

Leave a Reply