A lifting eye bolt, as shown in the below picture, is used for lifting and transporting heavy machines. It consists of a ring of the circular cross-section at the head and is provided with threads at the lower portion for screwing inside a threaded hole on the top of the machine. But how to choose the correct size of the Eye Bolt for your application? How to calculate the Eye Bolt Diameter based on the load?

We have been discussing the stresses in threaded bolts in the previous article. Now, this helps us to calculate the required diameter of the Eye Bolt to lift the load that we need to lift. And also helps us to choose the Eye Bolt size.

Tensile Stress in Eye Bolt

Typically we have seen these eye bolts in Lifting a machine for transporting or pulling a car with another vehicle using the towing hook. In all of these applications, the threaded portion of the Eye Bolt will experience tensile stress due to the external force.

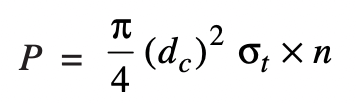

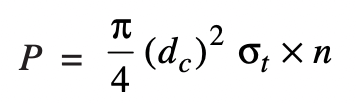

We know that the load that can be applied on the Bolt is calculated by the product of the permissible stress and Cross-sectional area

P = Permissible Tensile stress × Cross-sectional area of the Bolt

Let us say

σt = Permissible tensile stress for the eye bolt material

dc = Root or core diameter of the thread

n = number of bolts

We can write it as

From the above relation, if we have the amount of load and permissible tensile stress of the material of the Eye bolt, the core diameter (dc) of the Eye Bolt can be determined.

What are the design parameters for the Eye Bolt?

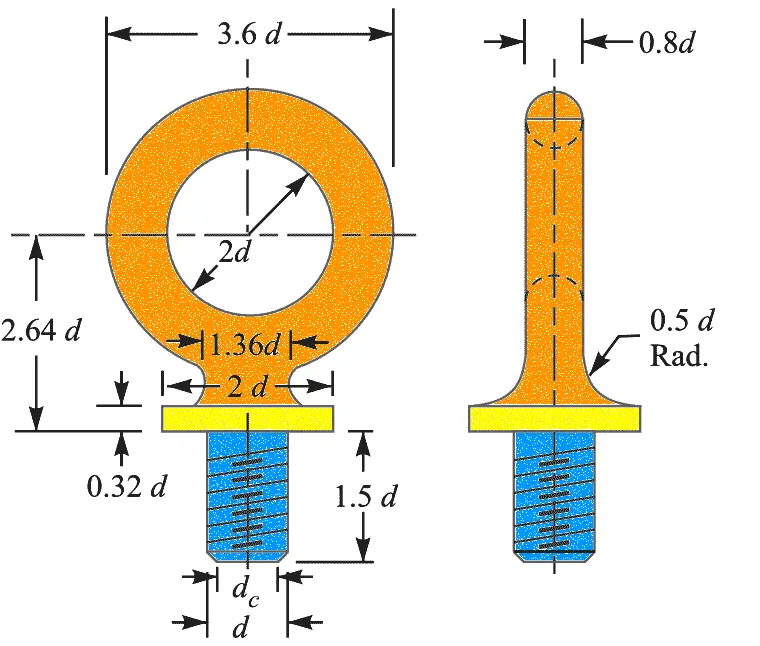

With the many experiments and testing done by engineers, Engineers have standardized the dimensional relation for the eye bolt design. All of these dimensions are depended on the Nominal diameter of the bolt, which can be identified from the Standard Design dimensions of the screw threads chart mentioned below.

Following is the schematic diagram for the eye bolt design dimensions.

From the above dimensions, we can design an Eye Bolt based on the given load need to be lifted. also, we need to have the permissible tensile stress of the eye bolt material.

Now let us take an example of how we can solve an example problem on the eye bolt diameter calculation and the other parameters of the eye bolt.

Example Problem on for finding Eye Bolt size and Eye Bolt design parameters

An eye bolt is to be used for lifting a load of 60 kN. Find the nominal diameter of the bolt, if the tensile stress is not to exceed 100 MPa. Assume coarse threads.

Answer:

Given Data

A static Lifting Load P = 60kN = 60×103N

Permissible Tensile stress σt = 100 N/mm2

From the above relation

60×103 = (π /4)×(dc)2 × 100 × 1

(dc)2 = 60000/78.55

(dc)2 = 764

dc = 27.6

Where dc is the core diameter of the bolt size. now we can get the nominal diameter of the bolt from the standard design screw threads table below.

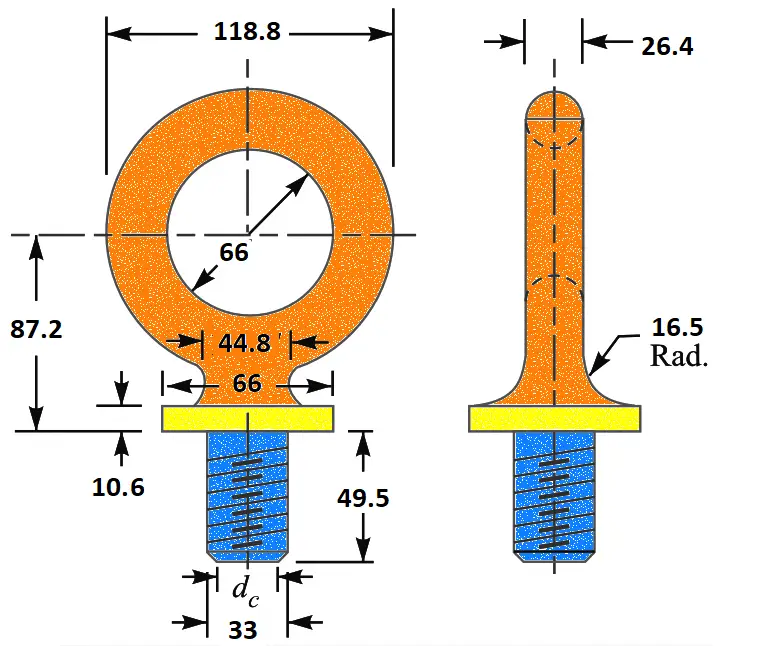

For the value of 27.6mm, the next closest dc value from the table is 28.706. The respective nominal diameter for this core diameter d is 33 and the bolt size is M33 bolt.

Now we have d = 33, From this, we can calculate the remaining parameters of the Eye Bolt. The following image shows all the calculated standard design parameters for the eye bolt.

Exercise Problems

1. An eye bolt is to be used for lifting a load of 30 kN. Find the nominal diameter of the bolt, if the tensile stress is not to exceed 100 MPa. Assume coarse threads from the below tables.

2. Four eye bolts are to be used for lifting a load of 280 kN. Find the nominal diameter of the bolts, if the tensile stress is not to exceed 100 MPa. Assume coarse threads from the below tables.

3. A machine of load 2534kN is to be lifted with help of eye bolts screwed on a rectangular frame. When we need to find out how many eye bolts are needed and what is the size of the eye bolt. The tensile stress should not exceed 90MPa. Assume coarse threads from the below tables.

Solve these and let us know the answers in the comment section below. I will help you.

Standard Dimensions of Screw Threads for Bolt and Nuts

According to IS: 4218 (Part III) 1976 (Reaffirmed 1996)

Coarse Threads Series

| Designation | Pitch mm | Major or nominal diameter for Nut and Bolt (d = D) mm | Effective or pitch diameter for Nut and Bolt (dp) mm | Minor or core diameter (dc) for Bolt in mm | Minor or core diameter (dc) for Nut in mm | Depth of thread for bolt -mm | Stress area mm2 |

| M 0.4 | 0.1 | 0.400 | 0.335 | 0.277 | 0.292 | 0.061 | 0.074 |

| M 0.6 | 0.15 | 0.600 | 0.503 | 0.416 | 0.438 | 0.092 | 0.166 |

| M 0.8 | 0.2 | 0.800 | 0.670 | 0.555 | 0.584 | 0.123 | 0.295 |

| M 1 | 0.25 | 1.000 | 0.38 | 0.693 | 0.729 | 0.153 | 0.460 |

| M 12 | 0.25 | 1.200 | 1.038 | 0.893 | 0.929 | 0.158 | 0.732 |

| M 1.4 | 0.3 | 1.400 | 1.205 | 1.032 | 1.075 | 0.184 | 0.983 |

| M 1.6 | 0.35 | 1.600 | 1.373 | 1.171 | 1.221 | 0.215 | 1.27 |

| M 1.8 | 0.35 | 1.800 | 1873 | 1.371 | 1.421 | 0.215 | 1.70 |

| M 2 | 0.4 | 2.000 | 1.740 | 1.509 | 1.567 | 0.245 | 2.07 |

| M 22 | 0.45 | 2.200 | 1.908 | 1.648 | 1.713 | 0.276 | 2.48 |

| M 25 | 0.45 | 2.500 | 2.208 | 1.948 | 2.013 | 0.276 | 3.39 |

| M 3 | 0.5 | 3.000 | 2.675 | 2.387 | 2.459 | 0.307 | 5.03 |

| M 35 | 0.6 | 3.500 | 3.110 | 2.764 | 2.850 | 0.368 | 6.78 |

| M 4 | 0.7 | 4.000 | 3.545 | 3.141 | 3.242 | 0.429 | 8.78 |

| M 4.5 | 0.75 | 4.500 | 4.013 | 3580 | 3.688 | 0.460 | 11.3 |

| M 5 | 0.8 | 5.000 | 4.480 | 4.019 | 4.134 | 0.491 | 14.2 |

| M 6 | 1 | 6.000 | 5350 | 4.773 | 4.918 | 0.613 | 20.1 |

| M7 | 1 | 7.000 | 6.350 | 5.773 | 5.918 | 0.613 | 28.9 |

| M8 | 1.25 | 8.000 | 7.188 | 6.466 | 6.647 | 0.767 | 36.6 |

| M 10 | 1.5 | 10.000 | 9.026 | 8.160 | 8.876 | 0.920 | 58.3 |

| M 12 | 1.75 | 12.000 | 10.863 | 9.858 | 10.106 | 1.074 | 84.0 |

| M 14 | 2 | 14.000 | 12.701 | 11.546 | 11.835 | 1.227 | 115 |

| M 16 | 2 | 16.000 | 14.701 | 13.546 | 13.835 | 1.227 | 157 |

| M 18 | 2.5 | 18.000 | 16.376 | 14.933 | 15.294 | 1.534 | 192 |

| M 20 | 2.5 | 20.000 | 18.376 | 16.933 | 17.294 | 1.534 | 245 |

| M 22 | 2.5 | 22.000 | 20.376 | 18.933 | 19.294 | 1.534 | 303 |

| M 24 | 3 | 24.000 | 22.051 | 20.320 | 20.752 | 1.840 | 353 |

| M 27 | 3 | 27.000 | 25.051 | 23.320 | 23.752 | 1.840 | 459 |

| M 30 | 3.5 | 30.000 | 27.727 | 25.706 | 26.211 | 2.147 | 561 |

| M 33 | 3.5 | 33.000 | 30.727 | 28.706 | 29.211 | 2.147 | 694 |

| M 36 | 4 | 36.000 | 33.402 | 31.093 | 31.670 | 2.454 | 817 |

| M 39 | 4 | 39.000 | 36.402 | 34.093 | 34.670 | 2.454 | 976 |

| M 42 | 4.5 | 42.000 | 39.077 | 36.416 | 37.129 | 2.760 | 1104 |

| M 45 | 4.5 | 45.000 | 42.077 | 39.416 | 40.129 | 2.760 | 1300 |

| M 48 | 5 | 48.000 | 44.752 | 41.795 | 42.587 | 3.067 | 1465 |

| M 52 | 5 | 52.000 | 48.752 | 45.795 | 46.587 | 3.067 | 1755 |

| M 56 | 5.5 | 56.000 | 52.428 | 49.177 | 50.046 | 3.067 | 2022 |

| M 60 | 5.5 | 60.000 | 56.428 | 53.177 | 54.046 | 3.374 | 2360 |

Fine Thread Series

| Designation | Pitch mm | Major or nominal diameter for Nut and Bolt (d = D) mm | Effective or pitch diameter for Nut and Bolt (dp) mm | Minor or core diameter (dc) for Bolt in mm | Minor or core diameter (dc) for Nut in mm | Depth of thread for bolt -mm | Stress area mm2 |

| M 0.4 | 0.1 | 0.400 | 0.335 | 0.277 | 0.292 | 0.061 | 0.074 |

| M 0.6 | 0.15 | 0.600 | 0.503 | 0.416 | 0.438 | 0.092 | 0.166 |

| M 0.8 | 0.2 | 0.800 | 0.670 | 0.555 | 0.584 | 0.123 | 0.295 |

| M1 | 0.25 | 1.000 | 0.838 | 0.693 | 0.729 | 0.153 | 0.460 |

| M 1.2 | 0.25 | 1.200 | 1.038 | 0.893 | 0.929 | 0.158 | 0.732 |

| M 1.4 | 0.3 | 1.400 | 1.205 | 1.032 | 1.075 | 0.184 | 0.983 |

| M 1.6 | 0.35 | 1.600 | 1.373 | 1.171 | 1.221 | 0.215 | 1.27 |

| M 1.8 | 0.35 | 1.800 | 1.573 | 1.371 | 1.421 | 0.215 | 1.70 |

| M2 | 0.4 | 2.000 | 1.740 | 1.509 | 1.567 | 0.245 | 2.07 |

| M 2.2 | 0.45 | 2.200 | 1.908 | 1.648 | 1.713 | 0.276 | 2.48 |

| M 2.5 | 0.45 | 2.500 | 2.208 | 1.948 | 2.013 | 0.276 | 3.39 |

| M3 | 0.5 | 3.000 | 2.675 | 2.387 | 2.459 | 0.307 | 5.03 |

| M 3.5 | 0.6 | 3.500 | 3.110 | 2.764 | 2.850 | 0.368 | 6.78 |

| M4 | 0.7 | 4.000 | 3.545 | 3.141 | 3.242 | 0.429 | 8.78 |

| M 4.5 | 0.75 | 4.500 | 4.013 | 3.580 | 3.688 | 0.460 | 11.3 |

| MS | 0.8 | 5.000 | 4.480 | 4.019 | 4.134 | 0.491 | 14.2 |

| M6 | 1 | 6.000 | 5.350 | 4.773 | 4.918 | 0.613 | 20.1 |

Conclusion

We have discussed how the Eye Bolt diameter can be calculated based on the load given and the permissible tensile stress. Also discussed are the Eye Bolt design parameters with example problems. Let us know what do you think about these in the comment section below.

Hi. What weight is a 14mm eye bolt with lifting capacity of 0.5T suitable for pulling a car?