In the Power transmission segment, gears have a significant role in transmitting the torque by the required velocity (transmission ratio) at the driver end to the driven end without any slipping. To begin with, first, we need to understand the Gear terminology, and followed by the different types of gears and their classification.

Gear Terminology

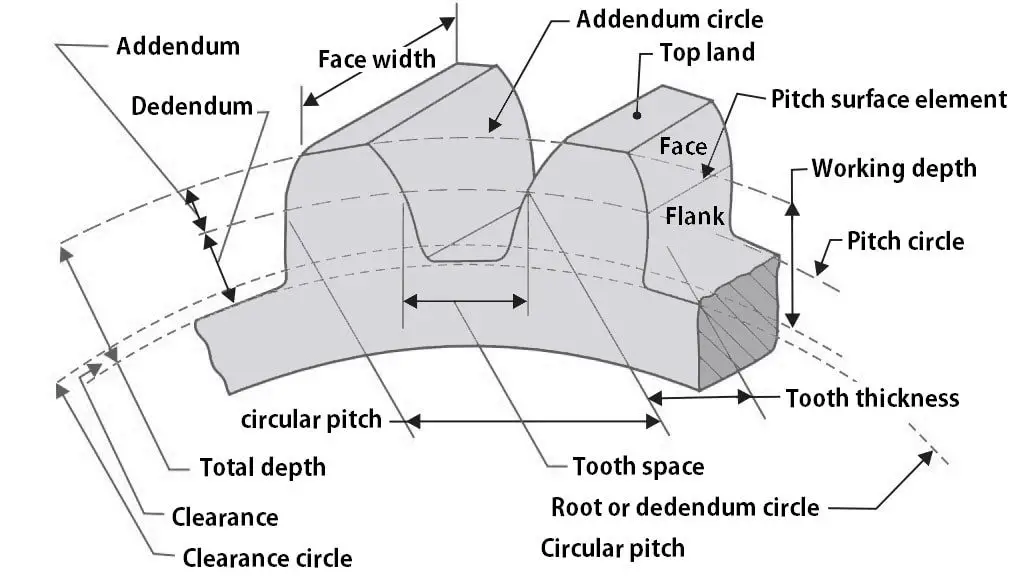

Following are the gear terminology generally we use, that should be understood clearly before begin with the Gear transmission subject.

What is Gear Module?

The Gear module represents actually how big or small the gear is. By mathematically it is the ratio of pitch circle diameter in millimetres to the number of teeth. It is usually denoted with m.

The gear module formula is m = D/T

What is the pitch?

In the subject of gears transmission, the pitch represents the size of each tooth on the gear.

Pitch Circle & Pitch circle diameter

Pitch circle is an imaginary circle, which by the pure rolling action, would give the same motion as the actual gear. The diameter of the pitch circle is called the Pitch circle diameter. The size of the gear is usually specified by the pitch circle diameter. It is also known as pitch diameter.

Pitch Point & Pitch surface

Pitch point is the common point of contact between two pitch circles, whereas the pitch surface is the surface of the rolling discs which the meshing gears have replaced at the pitch circle.

Pressure angle or angle of obliquity

The pressure angle or the angle of obliquity is the angle between the common normal to two gear teeth at the point of contact and the common tangent at the pitch point.

It is usually denoted by φ.

The standard pressure angles would be 14½° and 20°

Addendum & Addendum circle

The addendum is the radial distance of the tooth from the pitch circle to the top of the tooth. The circle drawn through the top of the tooth is called the addendum circle.

Dedendum & Dedendum circle

The dedendum is the radial distance of the tooth from the pitch circle to the bottom of the tooth. The circle drawn through the bottom of the tooth is called the dedendum circle. This dedendum circle is also known as the root circle

Circular Pitch

The circular pitch is the circumferential distance measured on the pitch circle from a point of one tooth to the corresponding point on the next tooth.

Circular pitch (Pc) = π D/T

(D = Diameter of the pitch circle, and T = Number of teeth on the wheel)

Diametral Pitch

Diametral pitch is the ratio of the number of teeth to the pitch circle diameter in millimetres.

Diametral pitch (Pd) = T/D = π/Pc

Clearance & Clearance circle

Clearance is the radial distance from the top of the tooth to the bottom of the tooth, in a meshing gear. A circle passing through the top of the meshing gear is known as clearance circle.

Total Depth

The total depth is the radial distance between the addendum and the dedendum circles of a gear. It is equal to the sum of the addendum and dedendum.

Working depth

Working depth is the radial distance from the addendum circle to the clearance circle. It is equal to the sum of the addendum of the two meshing gears.

Tooth thickness

Tooth thickness is the width of the tooth measured along the pitch circle.

Tooth space

Tooth space is the width of space between the two adjacent teeth measured along the pitch circle.

Gear Backlash

Backlash is the difference between the tooth space and the tooth thickness, as measured along the pitch circle. Theoretically, the backlash should be zero, but in actual practice, some backlash must be allowed to prevent jamming of the teeth due to tooth errors and thermal expansion. But too much backlash also should be avoided. That leads to the gear chatter in the gear boxes. Gear chatter means noise due to vibratory torque transmission through the gears.

Top land

Top land is the surface of the top of the tooth.

Face of tooth

The face of the tooth is the surface of the gear tooth above the pitch surface.

Flank of tooth

The Flank of the tooth is the surface of the gear tooth below the pitch surface.

Face width

Face width is the width of the gear tooth measured parallel to its axis.

Profile

The profile is the curve formed by the face and flank of the tooth.

Path of contact

Path of contact is the path traced by the point of contact of two teeth from the beginning to the end of the engagement.

These are the different terms used in the gears in gear terminology.

Conclusion

We have discussed all the different terms used in the gear terminology. If you have any further thoughts on this topic, let us know in the comment section below.

Leave a Reply