In the previous article, we have discussed the details regarding the Gear terminology. Now we will discuss the classification of Gears.

The gear wheels are basically classified by different criteria as follows.

- According to the position of axes of the shaft

- According to the position of teeth on the gear surface

- According to the type of gearing

- According to the peripheral velocity of the gears

1. Classification of Gears According to the position of axes of the shaft

According to the position of the shaft axes, there are 3 classification

- Parallel

- Intersection

- Non-parallel & Non-intersecting

Parallel

When the axis of the driveshaft and the driven shaft are in parallel, then this comes under this category. Here we can use the Spur Gear or helical gear to connect two parallel shafts and transmit the power.

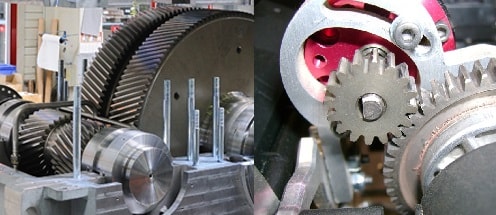

As we have shown in the above picture, the helical gears meshing and the spur gear meshing transmitting the power between the two shafts which are in parallel.

Intersecting

When two non-parallel shafts need to be connected then a bevel gears can do the job. This type of gearing called bevel gearing.

The tooth of the bevel gears also can be a spur or helical as shown in the above diagram. a helical toothed gears reduction in less noise than the spur gear meshing.

Non-parallel & Non-intersecting

When a shaft needs to be connected in a non-coplanar (non-parallel & non-intersecting) then spiral/skew bevel/hyperbolic gears will be used to transmitting the power.

The above-shown picture representation of the two non-coplanar shafts connected with the help of spiral gears.

As we have discussed the Classification of Gears According to the position of axes of the shaft, also we have discussed the different types of gear tooth arrangement. Those are straight tooth (Spur gear), an Inclined tooth (Helical Gear), Curved tooth (spiral gear). These are also one of the classifications of gears According to the position of teeth on the gear surface. So we don’t need to explain them again.

3. Classification of Gears According to the type of gearing

Based on the engagement of the gear, there 3 types of gears. they are

- External Gearing

- Internal Gearing

- Rack and pinion

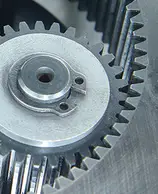

When the gear tooths is meshing externally then they come under the external gearing category. Example as shown in below

If the gears have meshed internally then they come under the internal gearing. Following is the example of internal gearing.

Rack and pinion are used to convert the linear motion into rotational motion or vice versa. the following picture will illustrate how a rack and pinion gearing would look like.

4. Classification of Gears According to the peripheral velocity of the gears

The classification of Gears according to the velocity of gears are 3 types

- Low velocity

- Medium velocity

- High velocity

The gears having a velocity less than 3 m/s are categorised under low-velocity gears.

The gears having velocity between 3 m/s and 15 m/s are comes under medium velocity gears.

If the velocity of gears is more than 15 m/s, then these are called high-speed gears.

These are the classification of gears according to the different criteria such as the gear tooth orientation, shaft alignments, and type of meshing, and velocity that they run.

Conclusion

We have discussed the classification of gears according to the type of meshing, and according to the shaft alignments, and according to the gear tooth orientations and the gear velocity. If you have any further thoughts on this topic, let us know in the comment section below.

Sundar, it’s interesting to know that gears can be classified according to the position of the staff axes. I like that you said helical gears and spur gears can be classified as parallel gears since they transmit power between two parallel shafts. I’ve been trying to learn more about gears because my dad is planning to open an auto shop in our ranch soon, and he wants me to help him out. He’s actually starting to fix our old truck, and he’s looking for a gear-cutting service nearby to make him some gears that would fix the truck. Thanks for this article!