Gas welding is a fusion type of welding, which uses the flame of an oxy-acetylene or hydrogen gas from a welding torch upon the surfaces of the prepared joint. There are different gas welding types based on the type of gas for the flame we use for the welding. Let us discuss more details about Gas welding and the equipment and types of flame used for this type of welding.

Gas Welding

The gas welding is made by applying the flame of an oxy-acetylene or hydrogen gas from a welding torch upon the surfaces of the prepared joint to melt and allow the molten metal to flow together to form the solid continuous joint upon cooling.

The intense heat at the white cone of the flame heats up the local surfaces to the fusion point while the operator manipulates a welding rod to supply the metal for the weld. This way the molten metal of the welding rod and the melted surfaces form the joint. A flux is being used to remove the slag. Since the heating rate in gas welding is slow, therefore this welding method is used when thinner materials need to be welded.

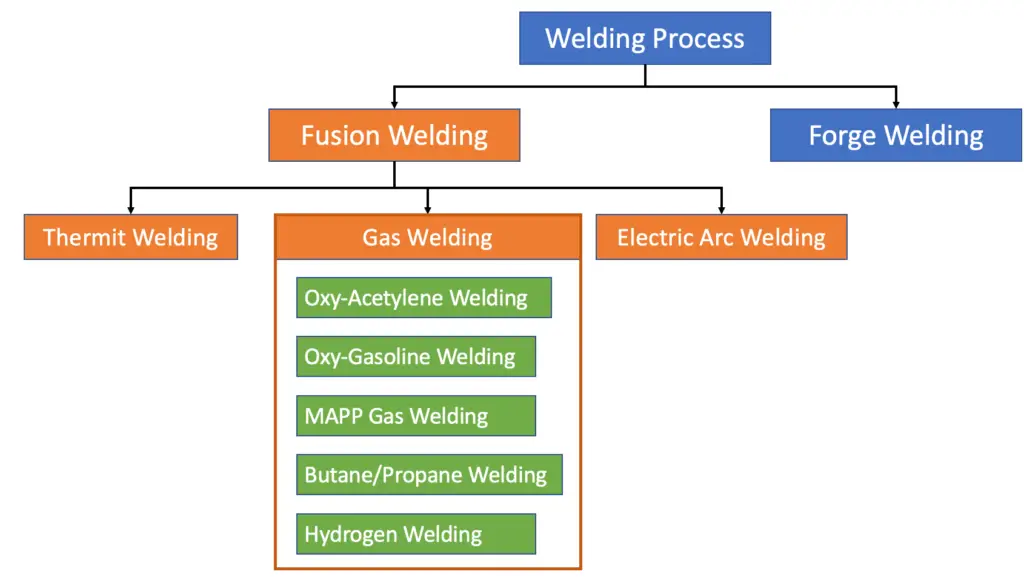

Gas Welding Types

There are 5 different Gas welding types. Those are

- Oxy-acetylene Welding

- Oxy-gasoline Welding

- MAPP Gas Welding

- Butane or Propane Welding

- Hydrogen Welding

All these Welding types are classified according to the type of gaseous mixture used for the torch. The equipmeant scheme remains almost the same and the welding procedure remains similar. This gas welding process can be applied for different applications. Let us discuss these Gas welding types individually in detail.

1. Oxy-acetylene Welding

- In this type of welding, the mixture of the Acetelyne gas and oxygen gas is supplied to the welding torch.

- This gaseous mixture provides the highest flame temperatures among the available fuel gaseous.

- That is the primary reason that this Oxy-acetylene gas welding is used generally for most of the applications.

- Although acetylene is the most expensive of all fuel gases.

- Acetylene is a volatile gas and requires specific handling and storage procedures.

2. Oxy-gasoline Welding

- In this type of welding, the mixture of the Pressurized Gasoline gas and oxygen gas is supplied to the welding torch.

- This Oxy-gasoline Welding is used in even more general application where the cost is an issue. and Specificall it is used to cut thick steel plates.

- This gasoline can be pressurized by a hand pump on the cylinder which gives more advantages to this type of welding used in more remote areas. this is most general practice.

3. MAPP Gas Welding

- MAPP means Methylacetylene-propadiene-petroleum.

- The Methylacetylene-propadiene-petroleum gas mixture is much more inert than other gas mixtures, and it is safe to use and easy to store for beginner and recreational welders.

- Methylacetylene-propadiene-petroleum can also be used at extremely high pressures, it is used in high-volume cutting operations.

4. Butane or Propane Welding

- Butane and propane are similar gases that can be used as separate as fuel gases or combined together.

- Butane and propane have lower flame temperatures when compared to acetylene.

- Butane and propane are less costly and easier to transport.

- Propane torches are used more often for soldering, bending, and heating.

- Propane needs a different type of torch tip than the injector tip because it is a heavy gas.

5. Hydrogen Welding

- This hydrogen gas welding is most commonly know for the underwater welding applications.

- The hydrogen can be utilized at higher pressures than other fuel gases.

- Some hydrogen welding equipment performs electrolysis by splitting the water into hydrogen and oxygen used in the welding process.

- Such electrolysis is often used for small torches, that we use in jewellery making process.

This is all about the different Gas Welding processes. now let us understand the importance of the adjustment of the flame in the torch for different kinds of welding operations.

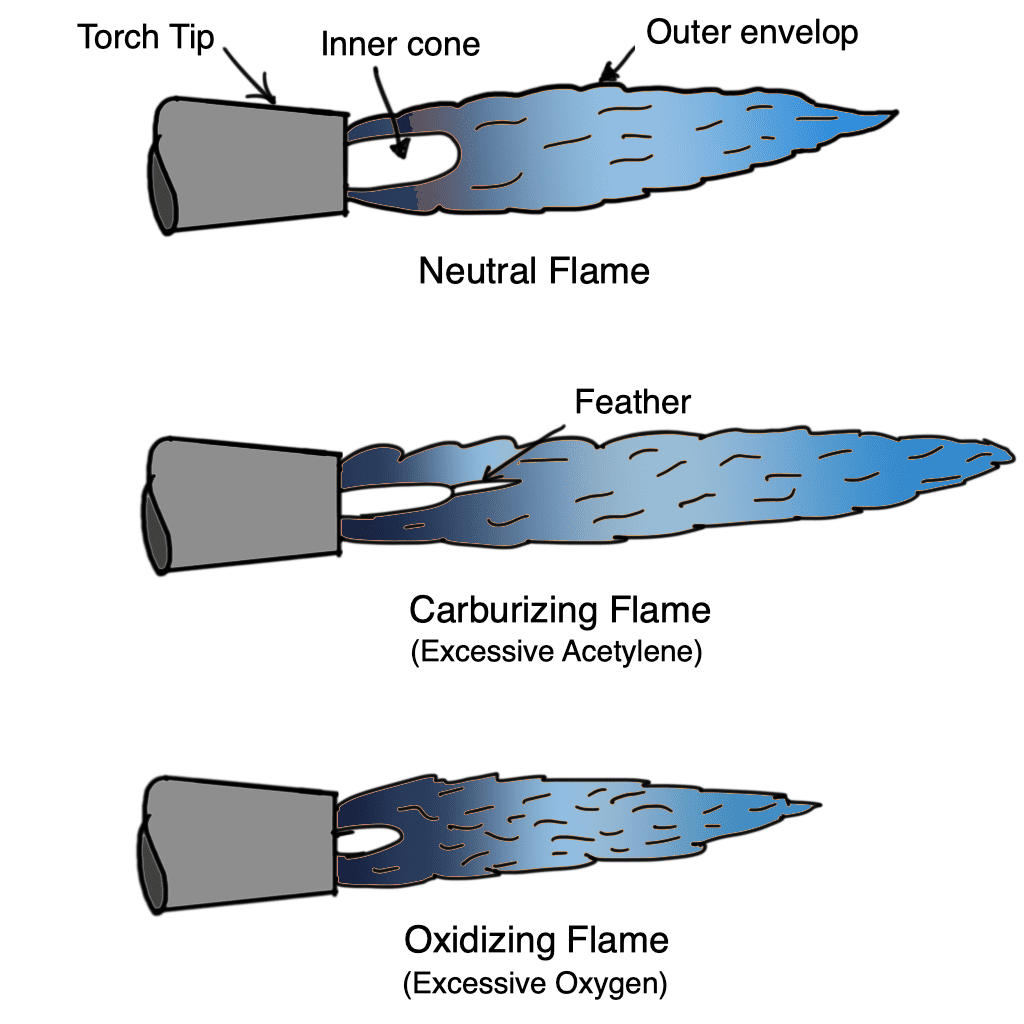

Gas Welding Flame Types

The accurate adjustment of the flame torch is a crucial task to perform welding for different applications. generally, there are 3 different adjustments. Let us understand this if we are working with the Oxy-Acetylene Gas welding.

Neutral Flame

- This flame is used for most desired applications.

- In this flame type, both Oxygen and Acetylene are equal amounts of volume is used.

- It has two zones. The inner cone zone and Outer envelope.

- Inner cone helps to produce heat and melt the metal. the Outer envelope protects the molten metal from oxidation.

- This welding torch is used to weld steel, cast iron, stainless steel, aluminium, copper metals.

Carburizing Flame

- In this flame type, less Oxygen and more Acetylene volumes are used.

- In this flame, there are three zones. The inner cone, the intermediate cone (feather) and the outer envelop.

- The Inner cone in this carburizing flame can produce more heat than the above newtral flame inner cone.

- the intermediate cone is produced as a result of excessive use of acetylene.

- This Carburizing flame is used to produce the hard and brittle weldments.

- Medium carbon steels, and nickel are welded with this kind of flame in gas weldings.

Oxidizing Flame

- In this flame type, more Oxygen and less Acetylene volumes are used.

- It has two zones. The small inner cone zone and Outer envelope.

- The small inner cone is not as sharp as the neutral flame of the carburizing flame due to the less fuel gas(acetylene).

- This oxidizing flame is used to weld the copper alloyes such as bross, and bronze.

- If we use this flame to weld steel, this weld result in large grain size, increased brittleness with lower strength and elongation. So we should not use it to weld manganese, steel, cast iron, zinc, copper, etc.

Gas Welding Equipment

- Cylinders

- Welding torch, Nozzel

- Control Valves and pressure regulators

- Protective gloves Helmet & goggles

Advantages of Gas Welding

Following are the main advantages of gas welding:

- Gas Welding has better control over temperature and filler- deposition rate.

- This weld dissimilar is suitable for metals.

- It is the most portable and versatile process.

- It has low maintenance and cost.

Disadvantages of Gas Welding

Following are the disadvantages of gas welding:

- It is not suitable for heavy conditions.

- Gas welding has a low working temperature of gas flame.

- Gas welding is not suitable for reactive metals and refractory.

- Flux shielding in gas welding is not so effective.

- More problems in storage and handling of gases.

Conclusion

We have discussed the Gas Welding types and the equipment used, and types of flames. The advantages and disadvantages are also the notable things while considering Gas Welding to your application. Let us know what do you think in the comment section belwo.

Leave a Reply