In the previous article, we have discussed different types of welding methods such as TIG welding, MIG welding, Arc welding, and Gas welding. All these welding methods are done on the two base metals to permanently fasten them together to withstand the applicable loads. choosing the best welding joint is also a crucial task for welder. In this article, we will see what are the different types of welding joints

Type of Welding joints

Basically, the welding joining types are grouped into two types

- Lap Joint

- Butt Joint

There may be further classification in these two groups of welding joints. let us discuss them each.

Lap Joint

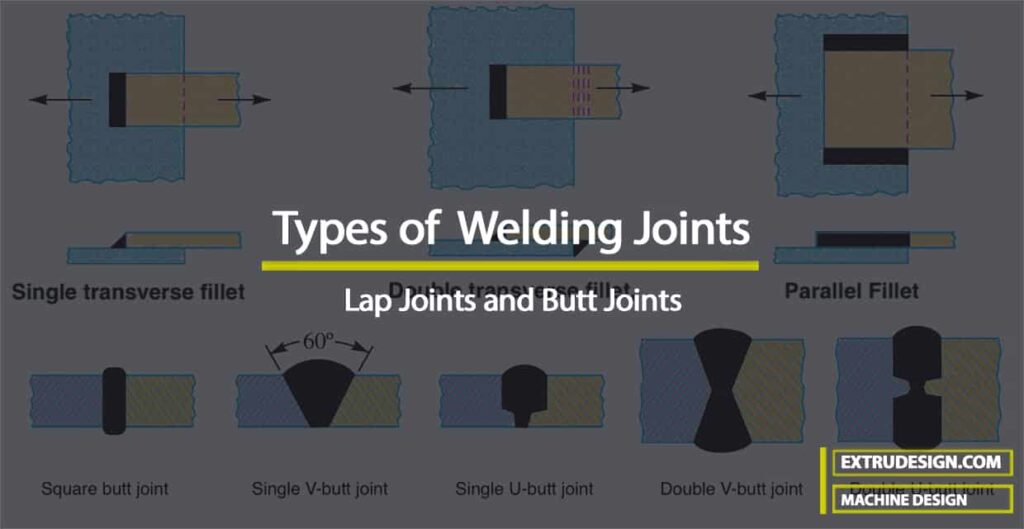

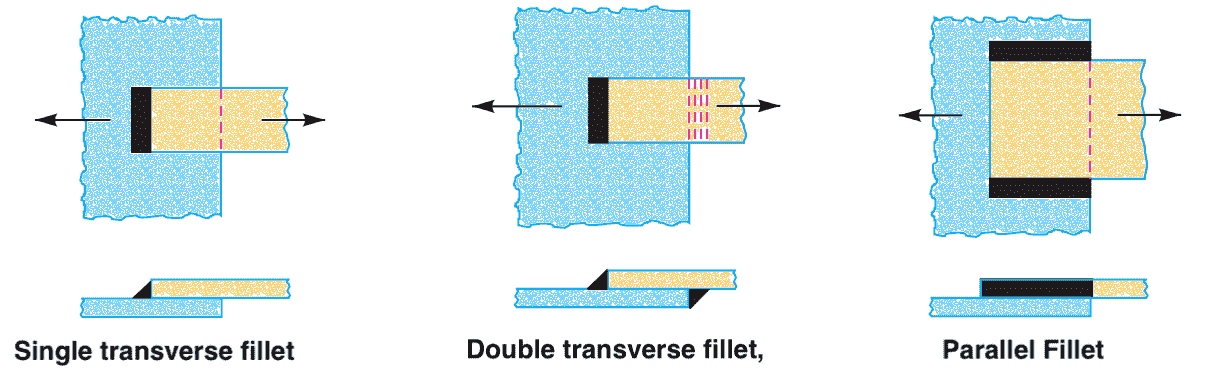

A lap joint can be made when two plates need to be welded then they will be welded by overlapping one on another. the welding is done at the edges of the two plates. Following is a schematic representation of welding tow plates in lap position.

- If the welding is done on one edge it is called the Single transverse fillet.

- Similarly, the welding is done on the two end edges in a transverse position then it is called the Double transverse fillet.

- If the two weldings are done on the same side with one pate then it is called the Parallel fillet joints.

These are the 3 different types of welding for Lap joints. The single fillet transverse joint and double fillet parallel joint also combine mostly as shown below schematic.

The strength of these joints can be calculated here!

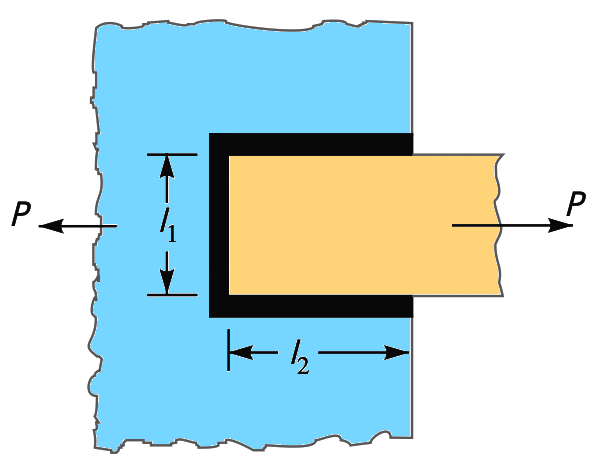

Butt Joint

The butt joint can be made by placing the edge of the two plates to the edge as shown in the above figure. for the plates of 5mm or less thickness, we do not need to bevel. if the thickness is more than 5mm and less than 12.5mm then the edges should be beveled to V or U-groove on both sides to add the filler material.

Based on this beveling of the shape on the plate edges, the butt joints can be made in different ways as shown in the above representations. Those are the

- Square butt joint

- Single V-butt joint

- Double V-butt joint

- Single U-butt joint

- Double U-butt joint

The strength of the but joint can be calculated here! Also read about the Heat Affected Zone in the weld joint.

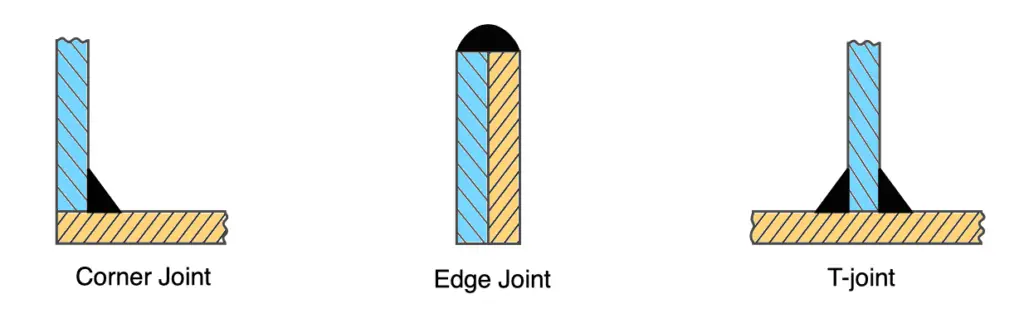

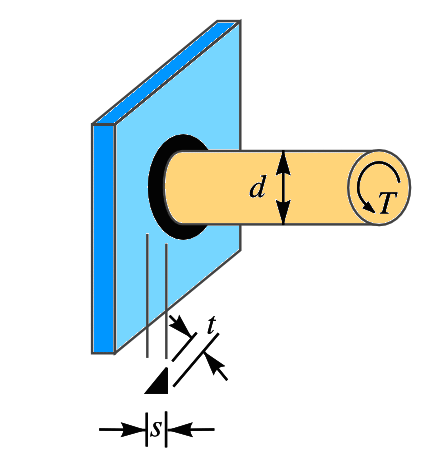

Along with these welding joints, there are other types of joints available are the corner fillet joint, edge joint, T-Joint, and Circular fillet weld joint as illustrated in the below picture.

But how we can select one of these welding joint types for our applications. What factors should we consider?

- The shape of the welded component required

- The thickness of the plates to be welded

- The direction of the forces applied

These are the main considerations involved in the selection of weld types. We also discussed the different types of welding processes such as TIG welding, MIG welding, Arc welding, and Gas welding. The method of welding also needed to be selected before going to select the welding joint type.

Conclusion

The weld joint may be in many forms, but what we have discussed are the most common types of welding joints and these help us to determine the strength of the welding joint. Let us know what do you think about this article in the comment section below.

Leave a Reply