A spring is defined as an elastic body, whose function is to distort when loaded and to recover its original shape when the load is removed. It absorbs or controls energy due to either shock or vibration so it can be used as shock absorbers and vibration dampers. It is also used to apply forces, as in brakes, clutches, and spring-loaded valves. Let us discuss some of the important types of Springs and their applications.

Applications of Springs

The various important applications of springs are as follows:

- To cushion, absorb, or control energy due to either shock or vibration as in car springs, railway buffers, aircraft landing gears, shock absorbers, and vibration dampers.

- To apply forces, as in brakes, clutches, and spring-loaded valves.

- To control motion by maintaining contact between two elements as in cams and followers.

- To measure forces, as in spring balances and engine indicators.

- To store energy, as in watches, toys, etc.

Types of Springs

Though there are many types of springs, the following, according to their shape, are important from the subject point of view.

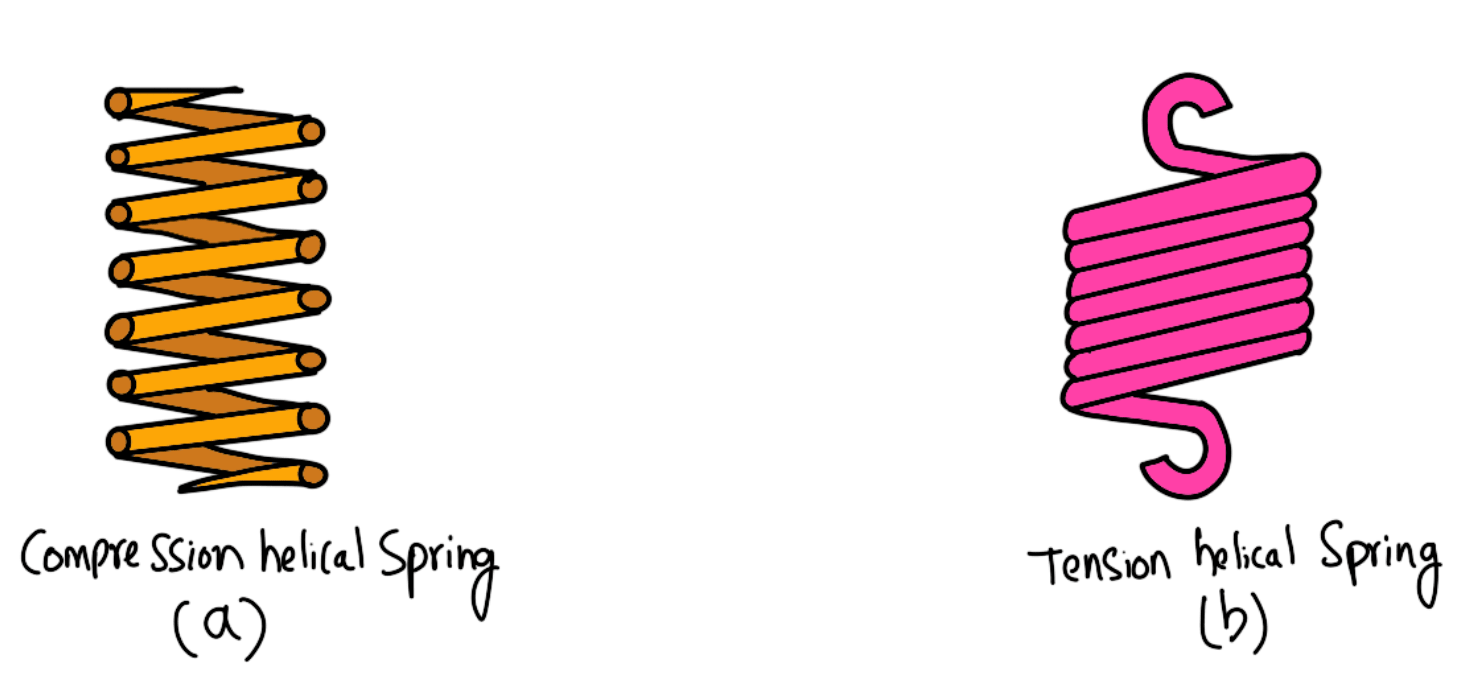

1. Helical springs

The helical springs are made up of a wire coiled in the form of a helix and is primarily intended for compressive or tensile loads. The cross-section of the wire from which the spring is made may be circular, square, or rectangular. The two forms of helical springs are compression helical springs as shown in the following figure(a) and tension helical springs as shown in figure (b).

The helical springs are said to be closely coiled when the spring wire is coiled so close that the plane containing each turn is nearly at right angles to the axis of the helix and the wire is subjected to torsion. In other words, in a closely coiled helical spring, the helix angle is very small, it is usually less than 10°. The major stresses produced in helical springs are shear stresses due to twisting. The load applied is parallel to or along the axis of the spring.

In open coiled helical springs, the spring wire is coiled in such a way that there is a gap between the two consecutive turns, as a result of which the helix angle is large. Since the application of open-coiled helical springs is limited, therefore our discussion shall confine to closely coiled helical springs only.

The helical springs have the following advantages:

(a) These are easy to manufacture.

(b) These are available in a wide range.

(c) These are reliable.

(d) These have a constant spring rate.

(e) Their performance can be predicted more accurately.

(f) Their characteristics can be varied by changing dimensions.

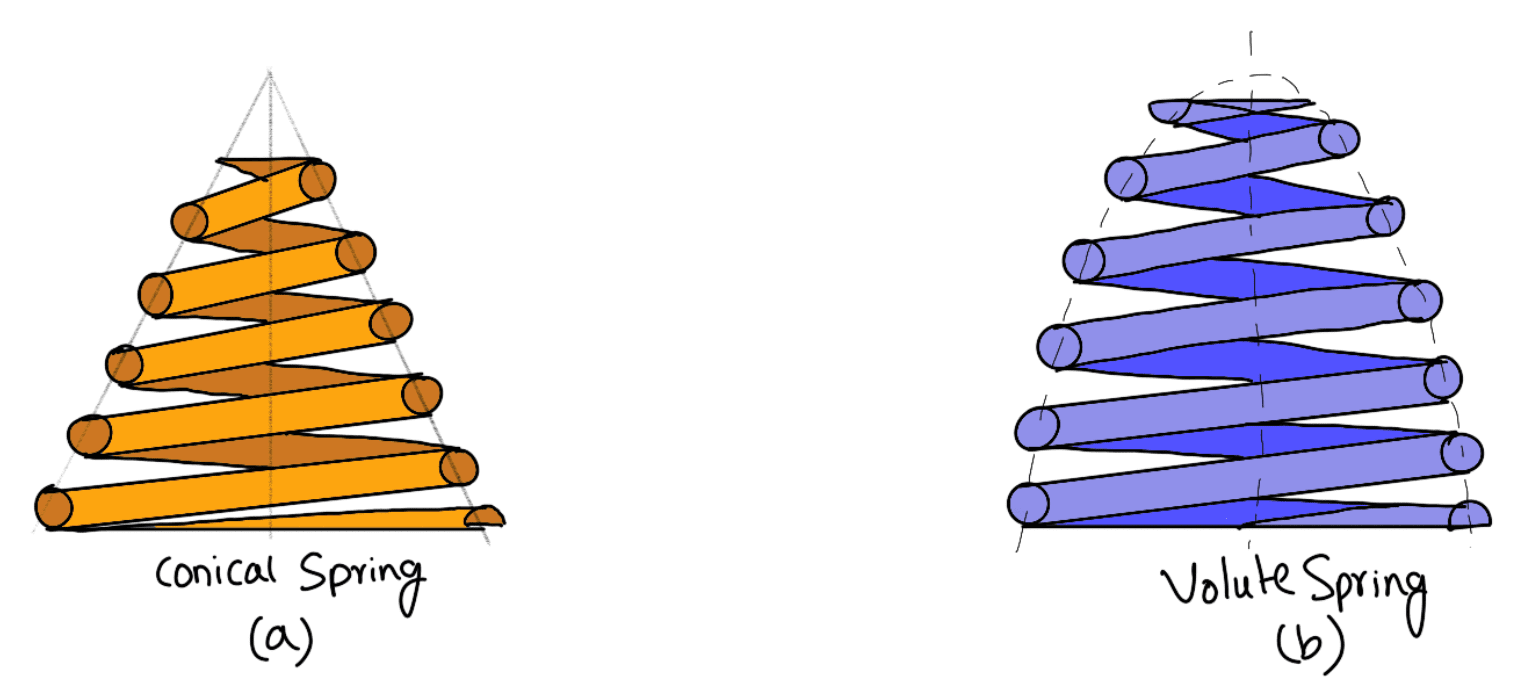

2. Conical and volute springs

The conical and volute springs, as shown in the following figure, are used in special applications where a telescoping spring or a spring with a spring rate that increases with the load is desired.

The conical spring, as shown in Figure (a), is wound with a uniform pitch whereas the volute springs, as shown in the following Figure (b), are wound in the form of a paraboloid with a constant pitch and lead angles. The springs may be made either partially or completely telescoping. In either case, the number of active coils gradually decreases. The decreasing number of coils results in an increasing spring rate. This characteristic is sometimes utilized in vibration problems where springs are used to support a body that has a varying mass.

The major stresses produced in conical and volute springs are also shear stresses due to twisting.

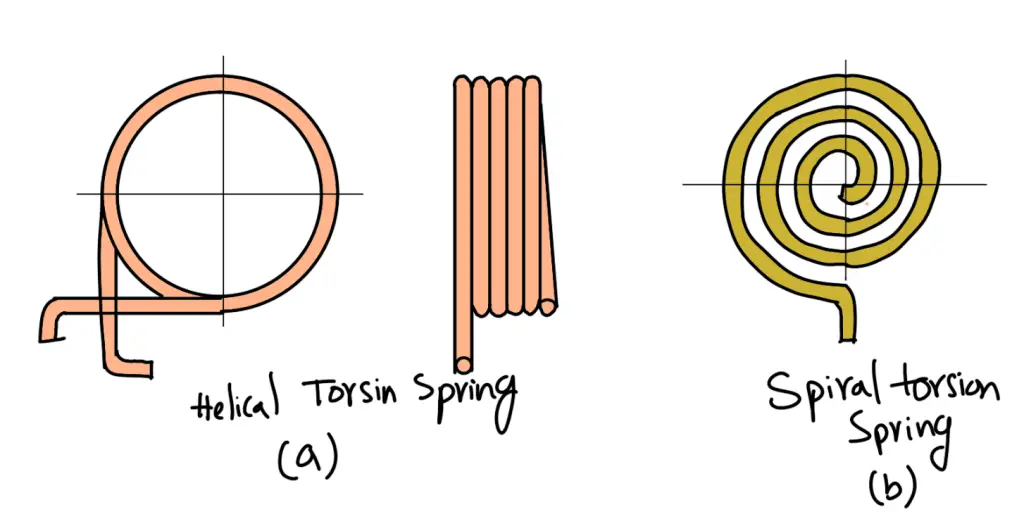

3. Torsion springs

These springs may be of helical or spiral type as shown in the following figure. The helical type may be used only in applications where the load tends to wind up the spring and is used in various electrical mechanisms. The spiral type is also used where the load tends to increase the number of coils and when made of flat strips used in watches and clocks.

The major stresses produced in torsion springs are tensile and compressive due to bending.

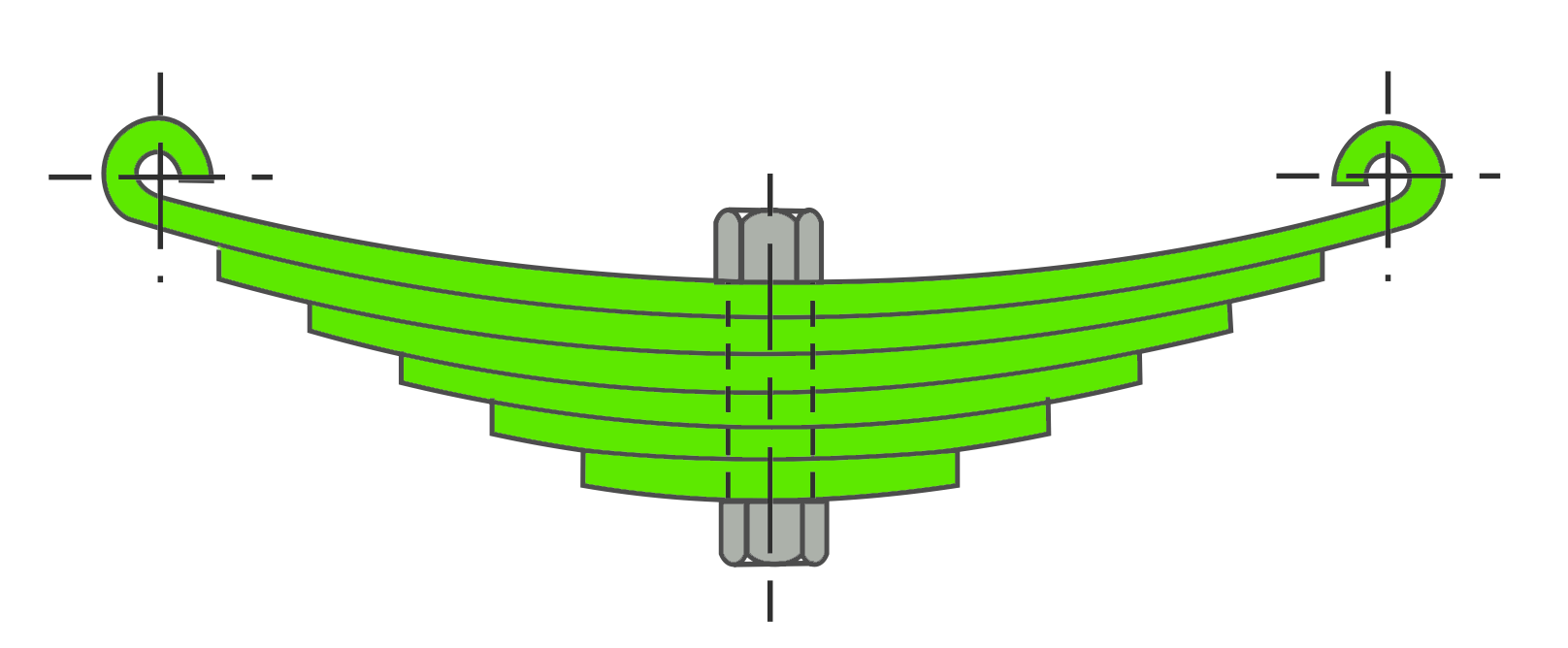

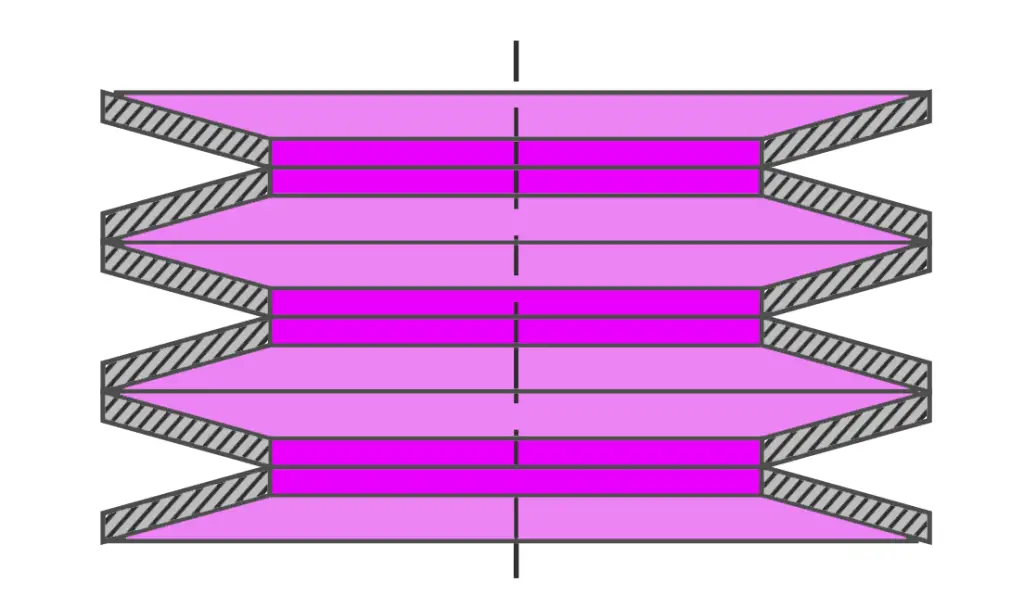

4. Laminated or leaf springs

The laminated or leaf spring (also known as flat spring or carriage spring) consists of a number of flat plates (known as leaves) of varying lengths held together by means of clamps and bolts, as shown in the following figure. These are mostly used in automobiles.

The major stresses produced in leaf springs are tensile and compressive stresses.

5. Disc or bellevile springs.

These springs consist of a number of conical discs held together against slipping by a central bolt or tube as shown in the following figure. These springs are used in applications where high spring rates and compact spring units are required.

The major stresses produced in disc or Belleville springs are tensile and compressive stresses.

6. Special-purpose springs

These springs are air or liquid springs, rubber springs, ring springs, etc. The fluids (air or liquid) can behave as a compression spring. These springs are used for special types of applications only.

These are the different types of Springs. Let us know if any other springs that we missed here in the comment section.

Leave a Reply