Project Title: Designing an Automated Production Line for a Manual Operating Recycling Plant

A Final year project on “Designing an Automated Production Line for Manual Operating Recycling Plant” was submitted by Abdelmalek Bouchema (from University of Sunderland United Kingdome )to extrudesign.com.

Abstract

Waste bread has been a growing issue in the Kingdom of Jordan, and this influenced the birth of an organization called Bread for Education. The organization found a solution to tackle this problem by collecting the waste bread that is later processed into food for livestock and allocated the profit to help give the unfortunate a better chance in their educational life. The growth in popularity came with an increase in demand from the market; this motivated the idea of having an automated production line. And this is the point where the project comes in, where an investigation was carried out on the old methods, followed by research on the possible approaches to a fully automated design. A prototype was designed, built, and tested in labs to have a clear illustration of how the actual production line will be working after the automation. In conclusion, out of four processes, Drying and Cutting were fully automated while Sorting appeared to be better-left manual after performing the weighted objectives method, and Mixing was automated but not in connection with the rest of the process. By reaching the results stage, the time taken in processing 20 kg of product, has significantly decreased from an average of 7 hours to 27.88 minutes as well as cutting down the number of workers present in the workplace that was ranging from 10-25 people to 2, depending on the workload.

Chapter 1: Introduction

Bread for Education is part of a bigger non-profit organization under the name of Recycling for Education based in the Kingdom of Jordan. Their job is to spread the mentality of recycling in Jordan by recycling waste into products that could be beneficial. And any profit made, is used to help the unfortunate students in their education by providing them with studying scholarships or stationary, books, backpacks, and other materials that are crucial for their educational life.

Bread has an exceptional value in the middle-eastern culture, “it is more of a symbol for dignity and a sign of life” Said Basim Al-Tuwaysi (Al-Tuwaysi, 2013). Thus, it is barely thrown away as rubbish, in fact, it is usually left on walls or streets for birds to feed on it, this makes the job of hunting for the left-out bread easier in places like schools, homes, restaurants or streets. As mentioned in an article by (Unversity of Sunderland, 2018), The initiative has proven a success as its founder, Abedalrahman Al-Zghoul, has received the Royal Medal for Excellence by his Majesty King Abdullah II of Jordan and was awarded by His Highness Sheikh Mohammed Bin Rashid Al Maktoum’s Global Initiatives Program.

According to (Zaid Obeidat, 2015), the yearly bread waste in Jordan is valued at 55,536,000 kilograms and costing the government a fortune of 210 million dollars. This large number motivated the organization to hold a small manual operating factory in Amman where the whole idea of bread processing is taking place. The outcome of this process is a product that is introduced to farmers and sold to them to be used as food for their livestock.

The organization is currently facing several challenges like the increased running costs due to the high number of workers, long-time taken in processing the bread to the final product and transportation costs that are scarcely covered. This has developed when the organization gained more popularity and acceptance in that area, meaning that there is a higher demand in the market, which leads to the need for enlarging the production rate. And to achieve this, the organization is seeking to automate its production line.

1.1 Aim

This project aims to design, build and test a prototype that will demonstrate the automation of a manual operating factory, then design the actual system to be implemented.

1.2 Objectives

- Complete an actual design of the production line

- Automation of Processes Involved

- Reduction of Overall Time

- Reduction of the Number of Workers

- Building and Testing a Prototype1.3 Project Scope

- Carry out a research on processes and components involved

- Complete a report regarding the project

- Choosing between most suitable methods or processes

- Discuss and evaluate the outcome of the project

- Study report and provide recommendations for further work

Chapter 2: Literature Review

In this part of the report, the whole system is divided into four main sections before it reaches the final product. Where each section explains a part of the process and research is conducted regarding possible automation systems, methods to be implemented and components to be used in the designing and building of the production line.

2.1 Batch and Continuous Processes

To start with, it is essential to know the two types of processing that split into Continuous and Batch processes. Continuous Processes involve handling the raw material constantly, and it is often used when the raw material is included in large amounts and not set to be regularly changed. They are considered to have lower running costs than batch processes in the long run (Naewbanij & Thepent, 1991) and (Stephanie Clark, 2004). As well as being more energy efficient and an easy method to handle the product being processed. (Mortaza Aghbashlo *, 2009) It is commonly used when the outcome does not involve products of high value.

Batch Processes are less complicated in terms of design but the time it takes is relatively longer, it basically works by dividing the processed material into groups, and these groups wait in a queue to get processed. Thus, it is used when the samples are involved in smaller amounts (Stephanie Clark, 2004). As stated by (Sunol, 1996), batch processing looks more into the variety of the product, unlike continuous processing. However, in the current case, the bread up to the cutting process should not face any charges, as all the bread experience the same conditions until it reaches the mixing stage.

2.2 Processes Involved

2.2.1 Sorting Processes

Since not all the collected bread is eligible to be undergoing the process, it needs to be classified. In the meantime, workers visually sort out the good bread from the contaminated or rotten.

A common type of sorting used nowadays in the food industry are Image Processing Systems which are considered a more accurate and reliable way in the approach of classifying objects (Cheng-Jin Du, 2004). The operation goes by using images of the objects being sorted and processes them digitally to check whether they meet the criteria in terms of size, texture, surface defect, color, or shape to be later classified. (Anuja Bhargava, 2018)

In a paper by (ABDULLAH, 2000) experimenting with quality inspection of bakery products using a color-based machine vision system, image processing could be used in the baking industry as it could be implemented in the quality control for muffins using the surface color. Furthermore, an article by The Guardian (Hern, 2015) mentions that computers are now more accurate compared to humans. As their accuracy rates reach 95.42% while it gets to about 95%, yet it can be noted that the difference is negligible, this would give a positive indication that it could also be used in the bread classification process, but more factors need to be considered to decide which method is optimum.

2.2.2 Drying Processes

In the heating process involved, the collected bread is dehydrated before being sent to the next process of cutting. According to (Fellows, 2009), Dehydration is the process of moisture removal from the bread by the application of heat to it. It is currently done by placing the bread on shelves and left to be dried using sunlight or by spreading the bread outdoor in the open air. This technique is not convenient since it is dependent on the weather and takes a very long time to be finished. This causes the production to be much lower during the winter since there is no to the limited presence of sun during the day and absence during the night. Moreover, the fact that the bread is left in such warm outdoor atmospheres makes it vulnerable to unwanted bodies like insects and dust (S. Öztekiṅ, 1999).

2.2.2.1 Drying using hot-air

(Lewicki, 2006) Says that drying using hot air is very commonly used in the heating industry due to the air being a good heat carrier. Furthermore, (Minguez-Mosquera, 1993) says that hot air drying prevents the food from the risk of being contaminated since the food is protected inside a cabin that holds the heat internally. The availability of its equipment and being energy efficient are also factors that lead this method ahead (Ho-Hsien Chen, 2005).

When hot air is flowing over the desired object, it continuously removes the moisturized layer forming on the surface of the object allowing it to dehydrate at a higher rate (Moreira, 2001). Additionally, it can be implanted to be continuously operating which is very important in this case as the processes in the new automated system are expected to work simultaneously.

2.2.2.2 Drying using sun and solar

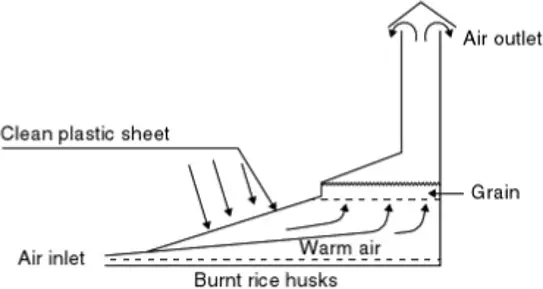

This process is rather an updated version of the process currently in use and not considered an automated version. It also uses the exposure of sunlight going through a transparent plastic sheet than by allowing air to flow on the food that is resting on shelves. (James G. Brennan, 2012) On the other hand, this process suffers from several drawbacks just like the current method in use as it is of the same mechanism with a more efficient way of delivering air to the product.

The following diagram is showing the mechanism of the solar drying process.

2.2.2.3 Drying using heated surfaces

Uses the principle of conduction by transferring heat from the surface to the food placed on the tray, evaporation occurs from the side opposite to the heated surface (James G. Brennan, 2012). They are typically used for small production sizes and are suitable for batch applications due to the limitation of space as their drying rate is dependent on the size of the heated surface the material sits on. Thus, valuable materials with higher thermal conduction are best suited for this method of dehydration.

In this application, the bread is expected to move to a different process when it is fully dehydrated. Therefore, a continuous drying method would be the most suitable for use, and as explained earlier the Hot-Air Drying can be set to be continuously running.

2.2.3 Cutting Processes

After the drying process, comes the cutting where the bread is shredded into tiny-sized pieces. The current machine used is a manual shredder like the one shown in Figure 2. However, it requires human interaction where an arm that is connected to one of the shafts and gets rotated by a person, and the other shaft is driven by the first since they are joined by the gear-shaped ends. This requires a fair amount of effort by the individual handling it, and as shown below in the pictures there are two people fixing the shredder in place to prevent it from shaking.

A low-cost approach regarding machinery equipment could be achieved by installing a motor to one of the shafts and allowing it to do the job of the personnel in charge. However, this depends on the condition of the current machines and might face drawbacks in the future regarding reliability and higher maintenance requirements.

2.2.3.1 Industrial Shredders

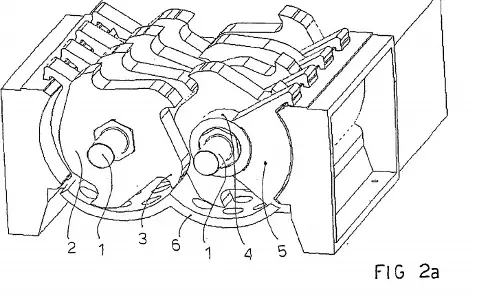

Due to the limited reliability of the previous method, a genuine way to be used is like the one shown in Figure 3.

Their functionality can be concluded by the double shafts (1) rotating against each other and each one of them has blades (2) with teethed edges (3). When they rotate, they do not get in contact with each other where each blade has a spacing on the opposite shaft.

The object needed to be shredded goes in between the shafts and downwards due to the direction of the shafts, then if the shredded object is of the right size it goes through the pores of the screen (6), and if not, it is pulled by the teeth to undergo the processes again. (Rota, 2015).

UNTHA Shredding Technology is a company that has manufactured a shredder for such organic waste applications. Their 2-Shaft Shredding System S40 shredder would be a fit option, its dimensions range from 750 – 1,450 mm in width and 700 mm in depth, providing enough space for the product (UNTHA, 2019). The design looks very similar to the one shown in Figure 4 and has the same running mechanism. Its simple design shown below gives it the advantage of being easy to maintain.

2.2.4 Mixing Processes

By reaching the end of the previous stage; its outcome should be ready as the final product. Mixing in this case is the addition of additives as required by the customer. As discussed earlier, there are two types of processing in the industry which are batch and continuous where each of them is used for different purposes. Since it is not involved in the making of the raw product and the outcome of it is determined by the customer, a batch mixing process will be more suitable for use.

According to (Bhesh Bhandari, 2013) Solid mixers could be divided into two types, Rotary (Tumbling) and Stationary mixers.

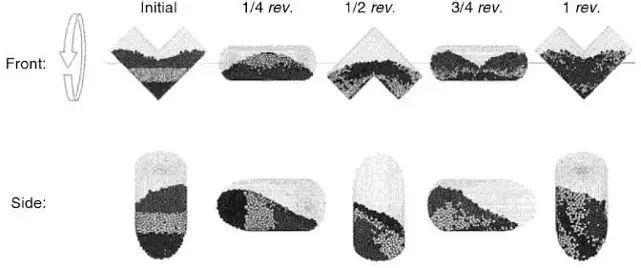

2.2.4.1 Rotary Mixers

Examples of Rotary Mixers are the V-Blenders, Drum Blenders, and the Double Cone Blenders. These operate by rotating the vessel itself, meanwhile, the particles inside get mixed by several flow-breaks that disturb the consistency of their flow.

They are preferred when large quantities are being dealt with due to their high loading capacity. Moreover, they are easy to use and install and typically used in the food industry (Maoqiang Jiang, 2011).

2.2.4.2 Stationary Blenders

On the other hand, there are stationary blenders that operate in a different way where the vessel here is fixed in place, and impellers do the job of mixing the particles using their rotational movement (Bhesh Bhandari, 2013). As (Paul, 2004) states in “Handbook of Industrial Mixing”, Their advantages consist of their flexibility when they are needed to be modified for particular applications and a more suitable option when cohesive materials are involved.

2.3 Components

2.3.1 Temperature Sensors

In the Drying process, the temperature inside the cabin must be set to the value at which the bread will start to dehydrate. Thus, it is important to choose a suitable type of sensor for this application according to the range of temperature it will be operating in.

2.3.1.1 Thermistors

According to (Nawrocki, 2005) in his book about Measurement Systems and Sensors, thermistors use the relationship between the resistance and the temperature to provide a reading. The relationship is not very linear between them thus it is used for applications where the temperature range is not required to be very high, usually to a maximum of (150- 350°C). They are of high sensitivity to temperature variations, low cost and has a compact size which gives it the advantage of being used in a vast range of temperature monitoring areas (Janata, 2010).

2.3.1.2 RTD (Resistor Temperature Detector)

RTDs are made of semiconducting materials with high melting points, Pt (Platinum) is usually used since it is able to provide ranges from (-200 – 850°C) due to its nature of having a practically linear relationship between the resistance and temperature (Ibrahim, 2002).

Below is a comparison table between the RTDs and Thermistors, information is provided by (OMEGA, 2019) :

| Sensor Type | Thermistor | RTD |

| Temperature Range (°C) | -100 to 325 | -200 to 650 |

| Accuracy | 0.05 to 1.5°C | 0.1 to 1°C |

| Long-term stability @ 100°C | 0.2°C/year | 0.05°C/year |

| Linearity | Exponential | Fairly Linear |

| Power Required | Constant Voltage or Current | Constant Voltage or Current |

| Response Time (s) | Fast 0.12 to 10 | Generally slow 1 to 50 |

| Susceptibility to Electrical Noise | Rarely Susceptible/High Resistance Only | Rarely Susceptible |

| Cost | Low to Moderate | High |

According to the above table and what has been mentioned earlier, Thermistors have an advantage over RTDs in terms of cost, sensitivity, response time, and long-term stability. On the other hand, RTDs are used over a broader range of temperature differences, but this factor is dependant on the amount of temperature required to dry the bread.

2.3.2 Controllers

To control the machines and be able to let them work in order with the required time limits and sequence, a controller has to be in charge.

2.3.2.1 Programmable Logic Controllers (PLC)

According to (Bolton, 2011), a PLC is a controller that is given orders on when to perform a function which could be starting a process or a machine. It has been made for those who do not have a good background in computer programming since it has been simplified to be less complicated for engineers to use. They are installed in industrial environments where harsh factors like dust, humidity, vibrations, and shaking are present. As well as, having a less complicated interface for controlling the operations and instructions going through the system.

A range of options are available when programming a PLC, as there are several languages that could be used when writing the code such as Instruction List (IL), Ladder Diagrams (LD), Function Block Diagram (FBD), providing the user with the ability to write the code at their personal preference making the whole idea of coding less complicated (Dunning, 2006).

The model Micro820TM Programmable Logic Controller made by Allen Bradley that could be used in this application, it gives a clear idea of the cost, voltage levels, Inputs/outputs, and the structure of a PLC, it provides up to twelve 24V DC Inputs and seven 24V DC Source outputs (Rockwell Automation, 2013).

2.3.2.2 Microcontrollers

Microcontrollers are components that are used to automate and control functions involved in processes or components. It is essential to ask where they are typically installed, as this would show up to what level they are able to perform in industrial areas. Based on (Udayashankara, 2013) in his book about 8051 microcontrollers, They are often used in much simpler applications compared with PLCs since they could be implemented in computer components and accessories, household appliances including washing machines and refrigerators.

An Arduino is a type of microcontroller that is available at a relatively low price and considered user-friendly having its own programming language, preventing the need to write a code using C language which is considered a more complex coding language.

However, it could be used as a reference to show how fitting it would be to use a microcontroller when controlling a whole automation system that consists of industrial machines. For example, they include two pins for supply voltage providing voltage at 3.3V and 5V (Arduino, 2019).

2.3.3 Conveyor Belts

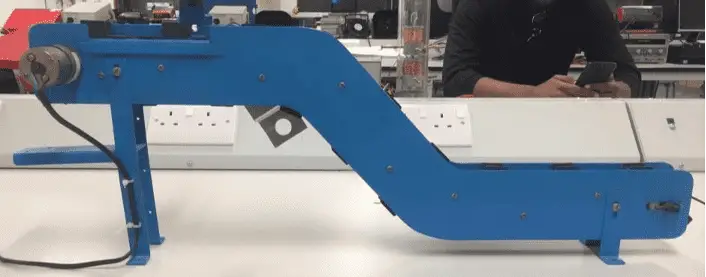

Two types of conveyors are expected to be used in the system which is allocated in the drying process and delivery of the bread from the drying to the cutting.

It is crucial to choose a type of conveyor belt in the drying processes that withstands high temperatures, meshed to allow hot air to pass through to the bread resting on it and is strong enough to hold the weight of the bread. Taking into consideration, that the openings in the belt must not be too big allowing the bread to slip through.

Wire conveyor belts would be a suitable choice, where it matches the criteria mentioned above and it is commonly used in the food industries around different areas including heating, drying, freezing, washing. (Adomaitis, 2018)

A proposed example of what could be used is the flat wire belt “PacTitan” by Cambridge Engineered Solutions. Available widths up to 6.5 meters, it also withstands temperatures up to 538 °C and is able to carry heavy-duty objects. (Solutions, 2019)

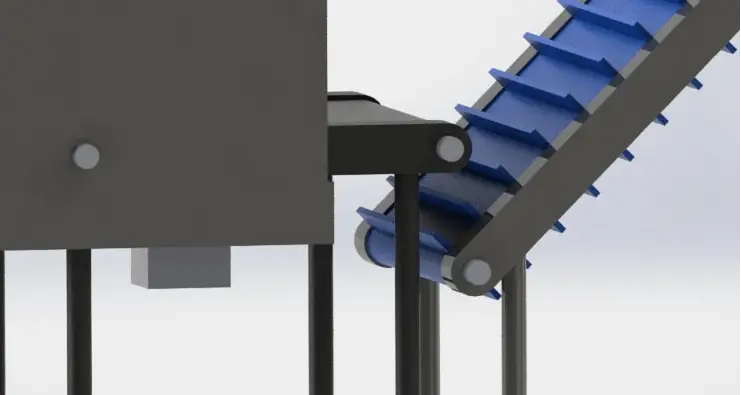

The second type of conveyor belt needed should be inclined so that it drives the bread upwards being the connection between the drying and the cutting processes. SYPSAL provides the “Inclined Belt Conveyor” which is an easily maintained inclined conveyor belt with the ability to hold heavy-duty objects. (SYPSAL, 2019)

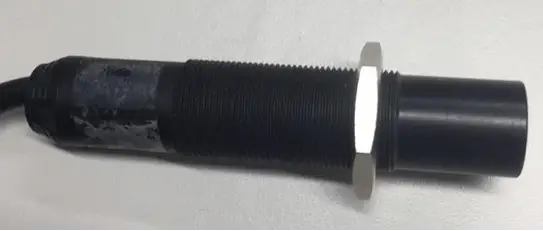

2.3.4 Proximity Sensors

Several Sensors are to be used in the process in designing of the new system. There is a wide range of sensors available, each of its own characteristics and uses.

As mentioned by (Gupta, 2011) in his book “Industrial automation and robotics”, Proximity Sensors are devices used for the purpose of detecting an object at a certain point of the production where that specific object is expected to be.

2.3.4.1 Capacitive Sensors

Hence comes the Capacitive Sensors, which are normally of small sizes of (1 x 5cm) in a cylindrical shape. Their low detecting range makes them a good option if needed in cases where the object has to be nearly in contact with the sensor. (Baxter, 1996 ). IFM supplies the model “KI6000”, which is a capacitive sensor with a detecting range of 0.5-40 mm (IFM, 2019).

2.3.4.2 Photoelectric Sensors

Photoelectric Sensors normally contain an emitter and a detector, and a signal is provided each time an object is detected. Unlike other sensors, they are not specified to a specific type of material. A great advantage of using such sensors is the big detecting range going up to 0.5 meters (Bartelt, 2006). An example of an industrial application where it could be used is given by (Juds, 1988) in his book about “Photoelectric sensors and controls” talking about a cookie motion detector in a temperature of 450°C, which is a similar application to what might be used in the drying phase (Automation24, 2019).

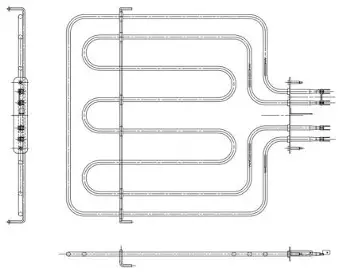

2.3.5 Heating Coils

Heating must be provided throughout the dehydration process, this could be provided using Tabular Heating Elements.

Tabular Heating Elements are typically used in baking ovens and can raise temperatures of air up to 700-800°C. They are generally bespoke and supplied up to the requirements of the customer (Hegbom, 1997). THERMOWATT provides these elements with the shape, size, and power decided by the customer.

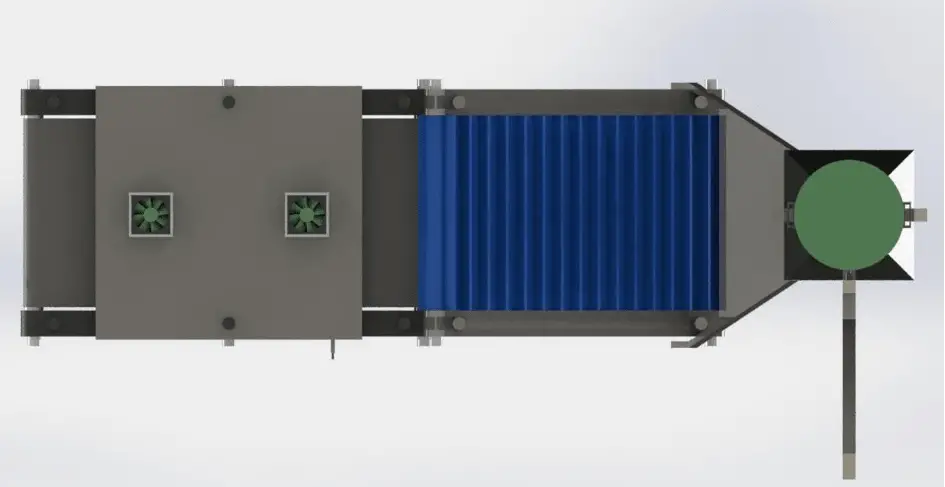

2.3.6 Fans

The heated air should be blown on the bread using fans. A lot of the new electrical heated ovens have built-in fans, this helps to achieve the desired temperature much faster and makes cooking a lot faster. Thus, these types of fans are manufactured to resist high temperatures, which is an important factor in the drying process since temperatures are expected to be raised significantly. (Lorcan, 2018)

Here is an example of the oven fans mentioned above, this model is manufactured by (Espares, 2019).

Chapter 3: Design and Methodology

3.1 Overview

An automated production line is to be designed and controlled to execute the required functions before being implemented. Decisions regarding options available for processes or machines will be taken and software called Solidworks will be used to demonstrate the design and layout of machines that will be used for the processes. And another software called Connected Components Workshop (CCW) developed by Rockwell Automation is used to perform the programming of the PLC for controlling the automated processes.

3.2 Sorting

3.2.1 Sorting Method Selection

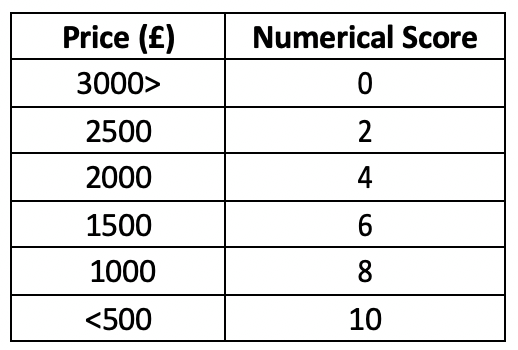

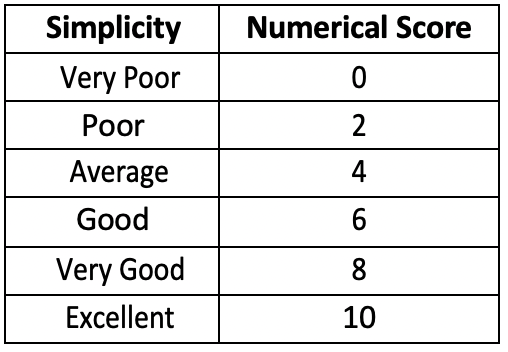

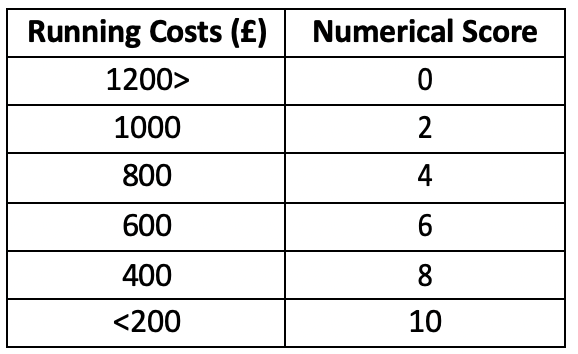

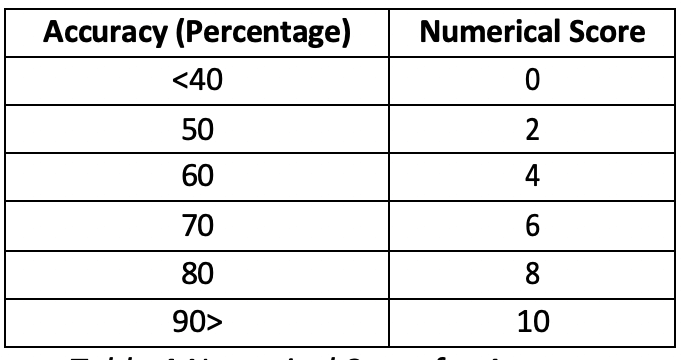

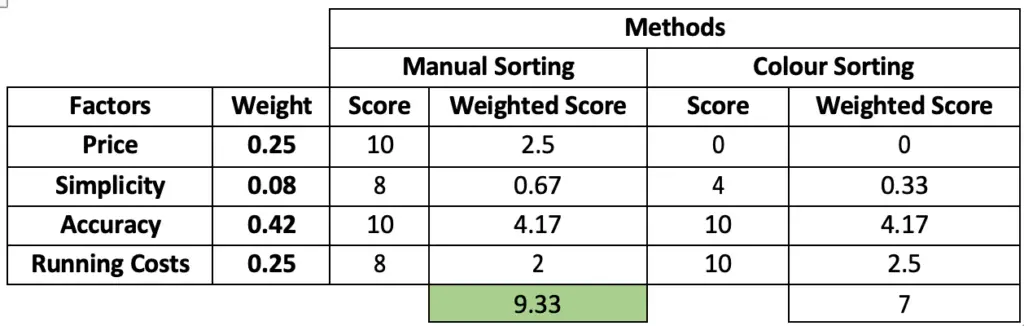

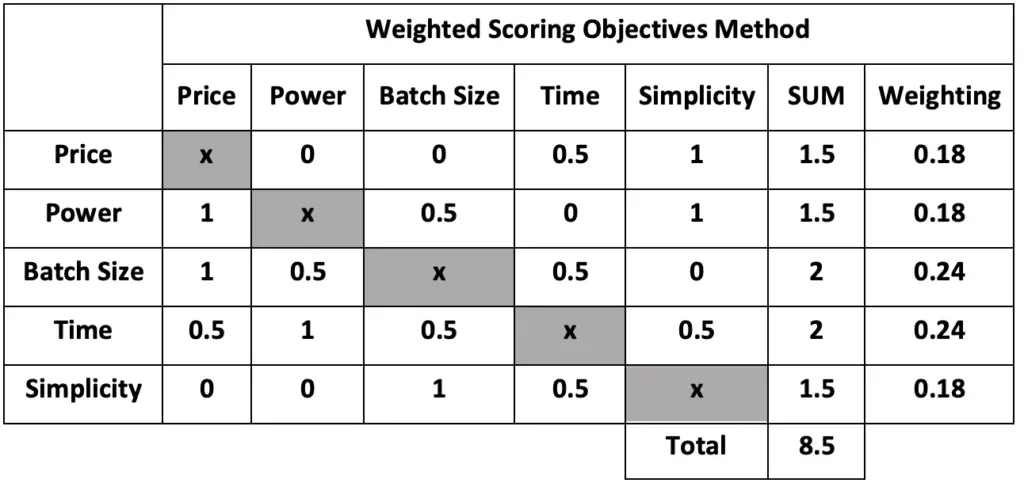

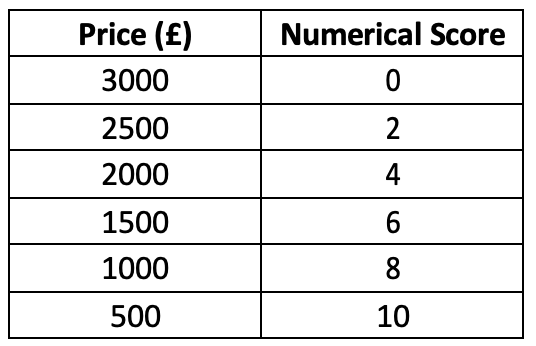

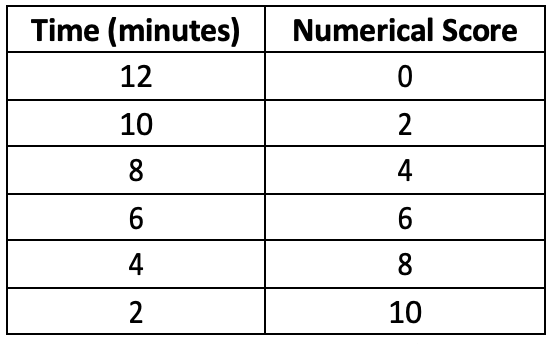

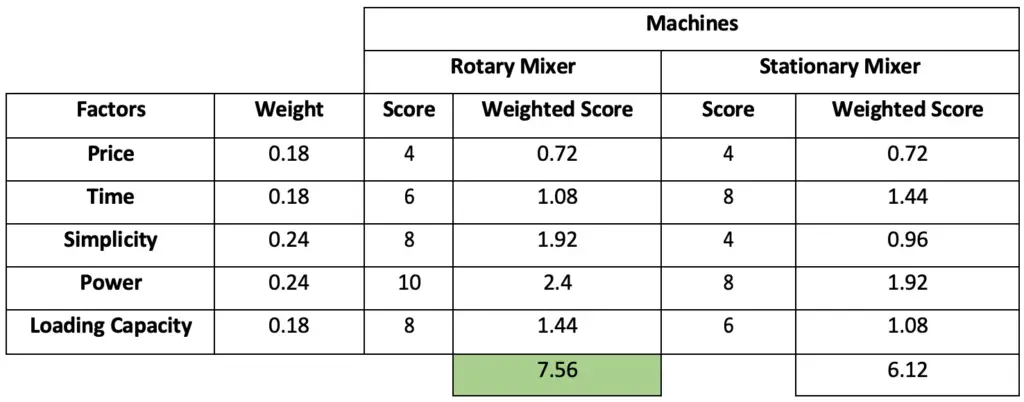

There are two possible ways of sorting one of which is manual and the other is by a color sorting machine. To help choose the most applicable of both, a weighted objectives method will be used. Performing a weighted objects method is a very efficient way of choosing between options as it gives importance to each factor taken into consideration.

This is performed by giving the factor with more significance a score of 1, a score of 0 when the factor is less significant and 0.5 when both factors share the same importance.

| Weighted Scoring Objectives Method | ||||||

| Price | Simplicity | Accuracy | Running Costs | SUM | Weighting | |

| Price | X | 0.5 | 0.5 | 0.5 | 1.5 | 0.25 |

| Simplicity | 0.5 | X | 0 | 0 | 0.5 | 0.08 |

| Accuracy | 0.5 | 1 | X | 1 | 2.5 | 0.42 |

| Running Costs | 0.5 | 1 | 0 | X | 1.5 | 0.25 |

| Total | 6 |

These are the factors that are believed to have the most influence on the choice, numerical scores have been set for each of their values.

According to the weighted objectives method, the Manual Sorting method has proven to be the most successful of the suggested methods.

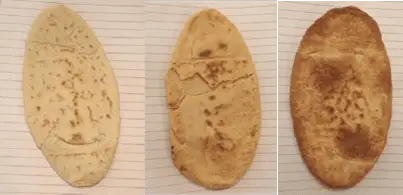

Since the leftover bread that reaches the site has no specific shape or size, this leaves the color as the most noticeable feature to take advantage of. By looking at Figure 11, the difference between moldy bread and fresh bread can be seen by eye, and easy for a human to tell which of the bread is eligible and which is not:

Figure 11: Pictures showing the difference between rotten and fresh Bread Source: (Kerr, 2017) and (RUPERTI, 2019)

As the manufacturer mentions that not much bread is thrown out for this reason, a simple procedure can be done manually by the person responsible of placing the bread on the dryer by inspecting the slices visually. This would benefit from their presence as it will not be limited to just one function.

3.3 Drying

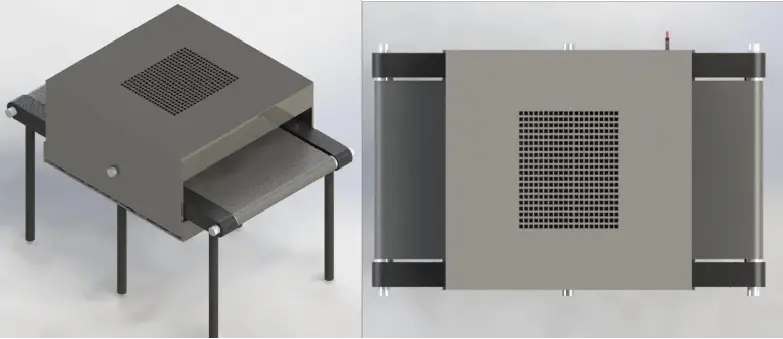

3.3.1 Dehydration System Design

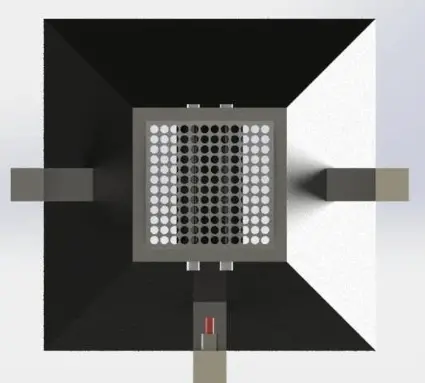

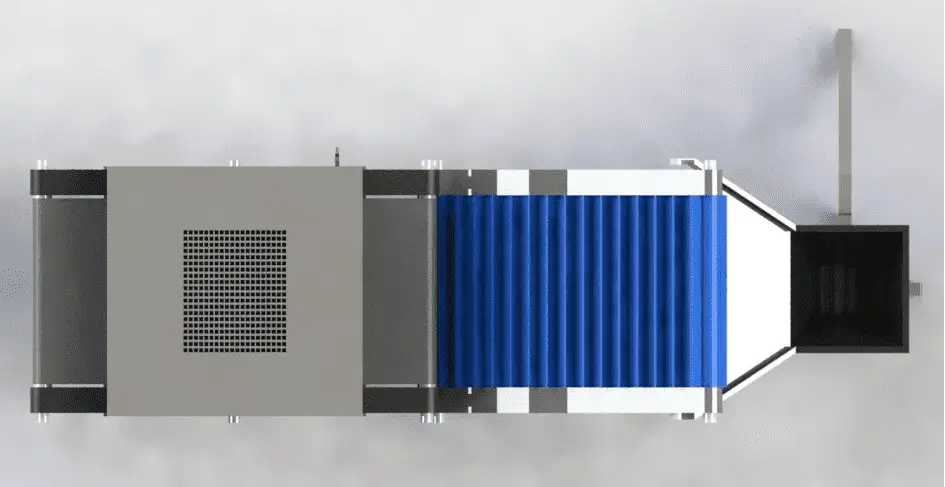

The proposed design for the drying system includes a meshed wire conveyor, where it receives the sorted bread from the left side and releases the dehydrated bread from the right side. A heating cabin prevents the heat from escaping to ensure the bread dries evenly. Moreover, the top of the cabin is meshed to allow the moisturized air to leave the cabin and get replaced by heated air from the bottom.

Dimensions of the cabin need to be determined, to make sure that it could hold the amount of bread needed to produce 20 kg of the product, to determine this, several calculations need to be performed.

Note that these calculations are made according to the assumptions that the bread is fresh, in one piece, and pita bread is taken as a reference while collecting the data, as it is the most commonly used bread in the Kingdom of Jordan.

The evaporation of water from the bread due to drying will cause its moisture content to drop from 32.5% when baked (Platat, 2015) to 9% when crispy as (Nieuwenhuijzen, 2008) says in his article about “Water Content or Water Activity: What Rules Crispy Behavior in Bread Crust?“, this means that there is a loss of 23.5% of water mass after drying.

The product is sold in 20 kg bags and to find the total amount of bread needed to be dehydrated, the loss in mass from the bread should be added to the value of the required amount:

(𝑹𝒆𝒒𝒖𝒊𝒓𝒆𝒅 𝒂𝒎𝒐𝒖𝒏𝒕 𝒙 𝑾𝒂𝒕𝒆𝒓 𝒍𝒐𝒔𝒕 %) + 𝑹𝒆𝒒𝒖𝒊𝒓𝒆𝒅 𝒂𝒎𝒐𝒖𝒏𝒕 = 𝑻𝒐𝒕𝒂𝒍 𝒂𝒎𝒐𝒖𝒏𝒕 𝒓𝒆𝒒𝒖𝒊𝒓𝒆𝒅 (𝟐𝟎 𝒙 𝟐𝟑. 𝟓%) + 𝟐𝟎 = 𝟐𝟒. 𝟕 𝒌𝒈

This means that 24.7 kg of fresh bread needs to be dried to produce 20 kg of bread.

The dimensions of 1 pita bread were measured 3 times, and the mean was calculated and listed below:

Length: (𝟏𝟖.𝟒+𝟏𝟖.𝟏+𝟏𝟖.𝟔)/3 = 𝟏𝟖. 𝟑𝟕 𝒄𝒎

Width: (𝟏𝟑.𝟒+𝟏𝟐.𝟗+𝟏𝟑.𝟑)/3 = 𝟏𝟑. 𝟐𝟎 𝒄𝒎

Mass of one pita: (𝟓𝟗+𝟓𝟕+𝟔𝟑)/3 = 𝟓𝟗. 𝟔𝟔 𝒈𝒓𝒂𝒎𝒔

The area took by one pita bread: 𝟎. 𝟏𝟑𝟐 𝒙 𝟎. 𝟏𝟖𝟑𝟕 = 𝟎. 𝟎𝟐𝟒𝟐𝟒𝟖 𝒎𝟐

The area of single pita bread is considered a rectangle since the bread should never be on top of

each other to make sure heat is spread evenly over it.

Number of pita bread in 24.7 kg: 𝟐𝟒.𝟕/𝟎.𝟎𝟓𝟗𝟔𝟔 = 𝟒𝟏𝟒. 𝟎𝟏 ≈ 𝟒𝟏𝟒 𝒖𝒏𝒊𝒕𝒔

Total area required to fit 24.7 kg worth of bread (cabin area):

𝑵𝒖𝒎𝒃𝒆𝒓 𝒐𝒇 𝒖𝒏𝒊𝒕𝒔 𝒙 𝑨𝒓𝒆𝒂 𝒕𝒂𝒌𝒆𝒏 𝒃𝒚 𝒐𝒏𝒆 𝑷𝒊𝒕𝒂

𝟒𝟏𝟒 𝒙 𝟎. 𝟎𝟐𝟒𝟐𝟒𝟖 = 𝟏𝟎. 𝟎𝟑 𝒎𝟐≈𝟏𝟎 𝒎𝟐

According to the calculations, the area of the cabin should be 10 m2. A 2 m wide by 5 m Long dimension can be used for the cabin to match that area.

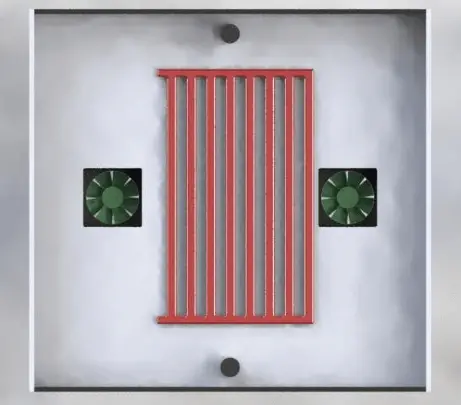

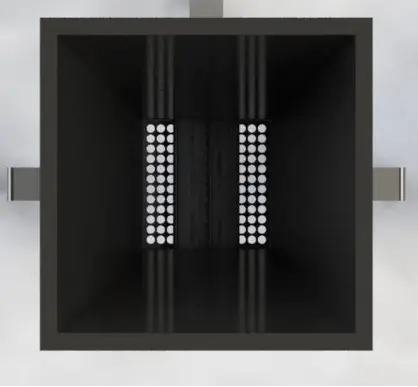

Carrying on with the rest of the design, Figure 13 shows a section view of the system, demonstrating the bottom of the cabin where the heating coils and the fans are placed.

Air is heated using the electrical heating coils and driven upwards by the fans that blow the heated air through the meshed conveyor and on the surface of the bread. As shown below, the fans sit below the cabin to be away from the heating coils since they can not withstand the high temperatures supplied by the heating coils.

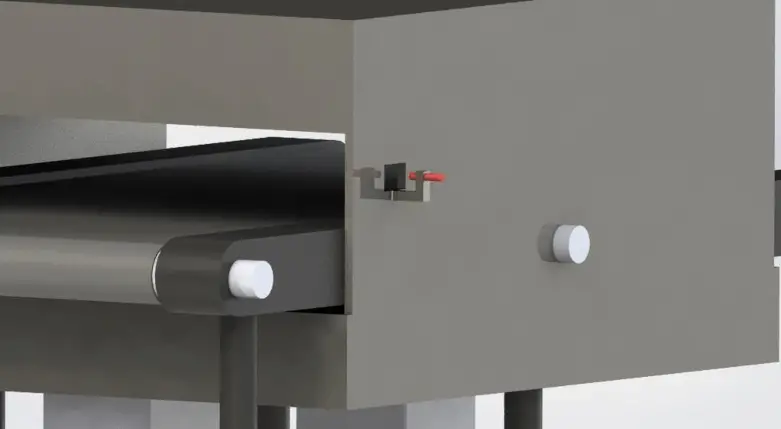

Looking at a back view of the system, a photo-electric sensor can be noticed, it works by giving a signal to the PLC indicating that the cabin is full to start the dehydration process.

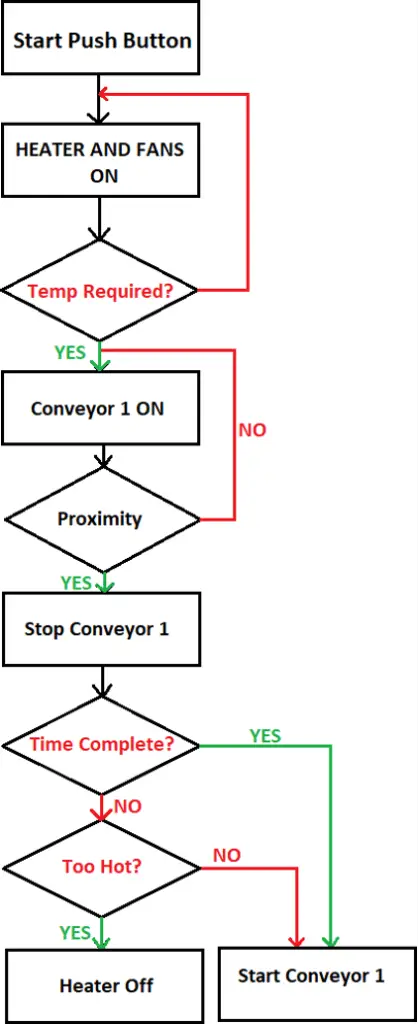

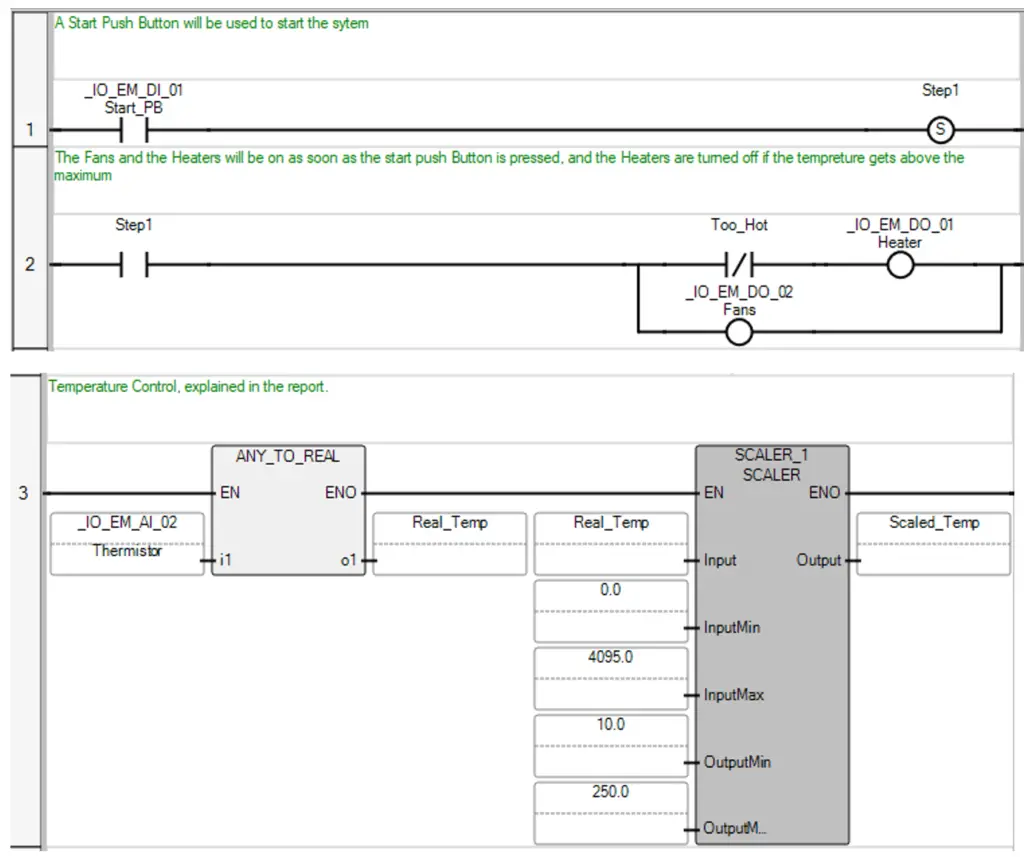

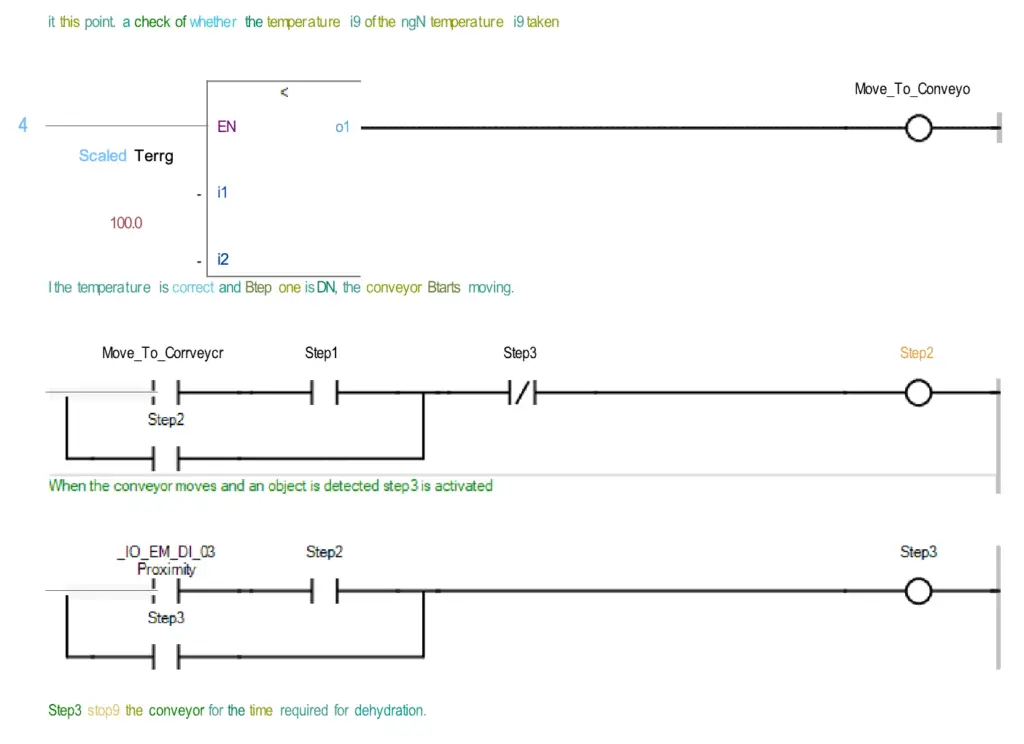

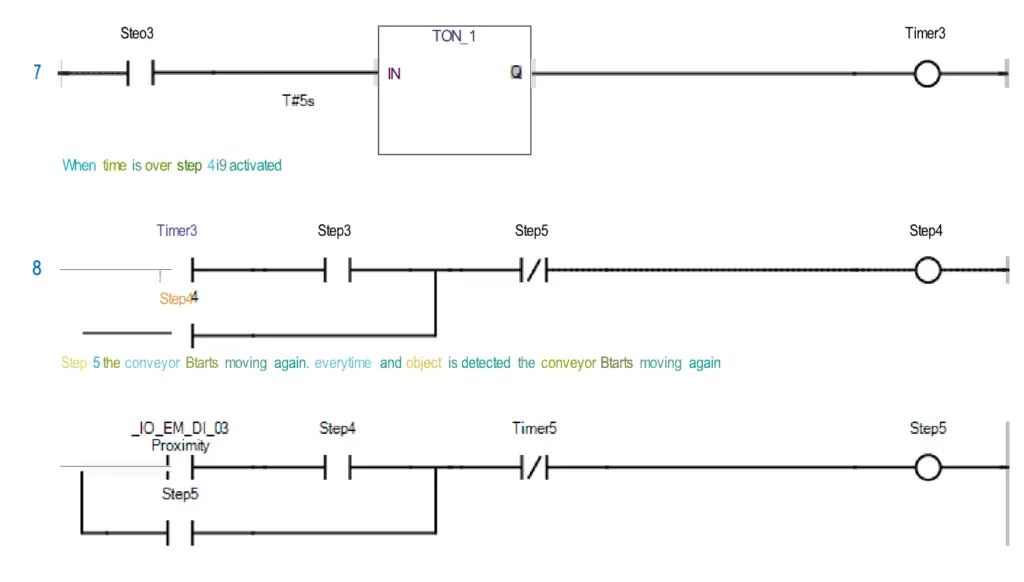

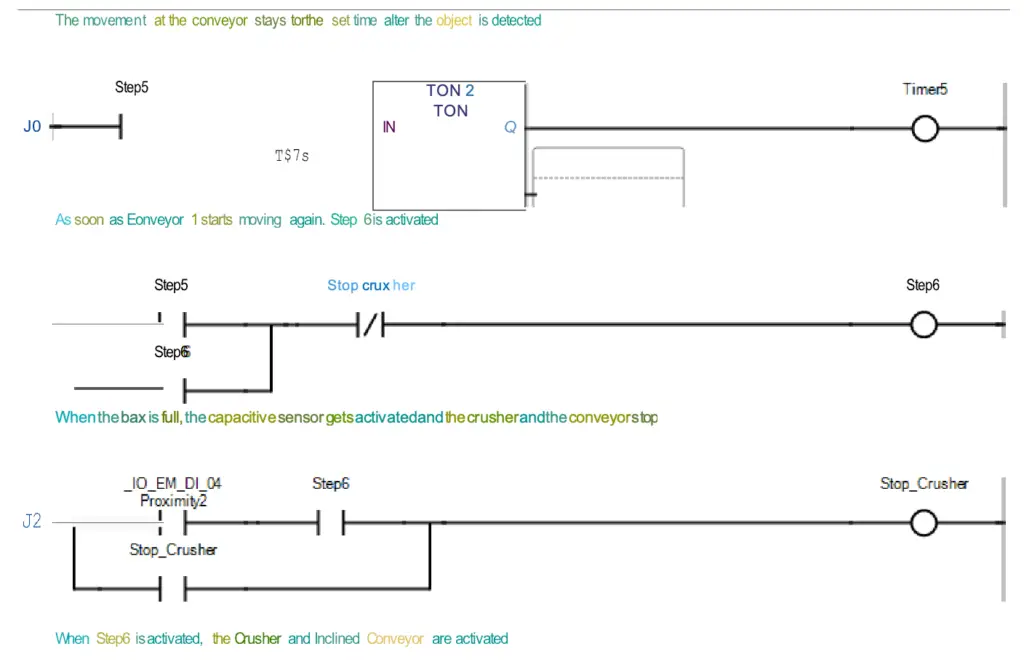

3.3.2 PLC programming for the Dehydration Process

A flowchart showing the actions taken by the PLC the drying process is shown below:

The heating process starts by clicking a start Push Button that will turn the heating coils and the fans ON. By going back to the literature review, it is noted that a Thermistor will be used for temperature control inside the cabin, and as it gets to the required point, the conveyor

will start moving. Meanwhile, a person will be placing the bread on top of it until it reaches a proximity sensor that will stop the conveyor at a point where all the bread is inside the cabin. After the bread is dehydrated for the set time, the conveyor starts again to shift into the next process

INPUT/OUTPUT list:

| Allocation | Inputs | Allocation | Outputs |

| _IO_EM_DI_01 | Start Push Button | _IO_EM_DO_01 | Heating Coils |

| _IO_EM_DI_02 | Temperature Sensor | _IO_EM_DO_02 | Fans |

| _IO_EM_DI_03 | Proximity Sensor | _IO_EM_DO_03 | Conveyor Belt 1 |

3.3.3 Temperature Control

Controlling the Temperature was the primary function in this process, as the temperature must be set at the right value decided by an experiment done later. Since the dehydration of the bread might lead to burning it and becoming disqualified from the whole process. The thermistor in the cabin will be reading the temperature continuously as the heaters are turned on and it will provide an analog value that will be sent to the PLC as an Input. Inside the program, a function block called “Any_to_Real” will change the result of the Analogue to Digital conversion to a real number to allow calculations to be made in the PLC software. Then comes a “Scaler” which is another function block that translates the analog results taken, into a meaningful value between the maximum and minimum temperatures obtained from the thermistor. Then a Comparator is added to check if the readings are below the temperature set, to turn the heaters on. Another comparator is used to maintain the temperature below the maximum value allowed, and it turns off the heater if the value gets over that point.

Using the software CCW, a code was written and downloaded on a Micro820TM PLC containing functions shown and explained earlier in the flowchart, for full code see Appendix 1.

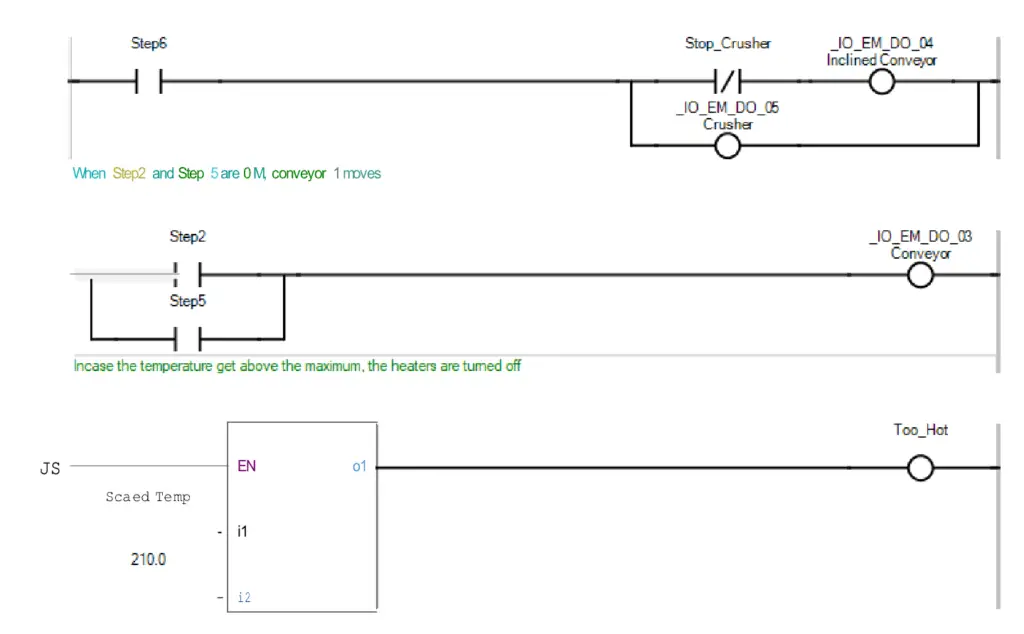

3.4 Cutting

3.4.1 Cutting System Design

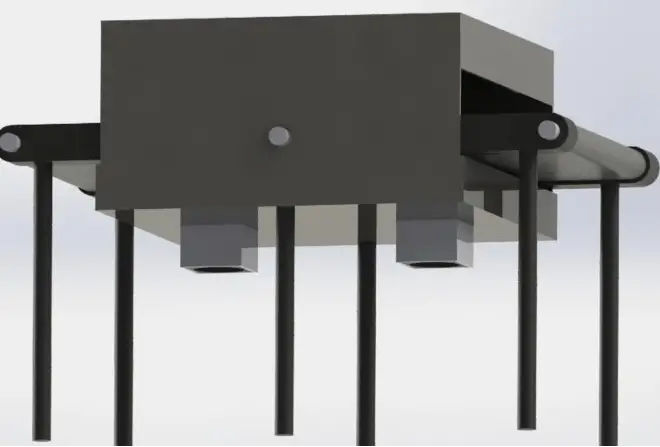

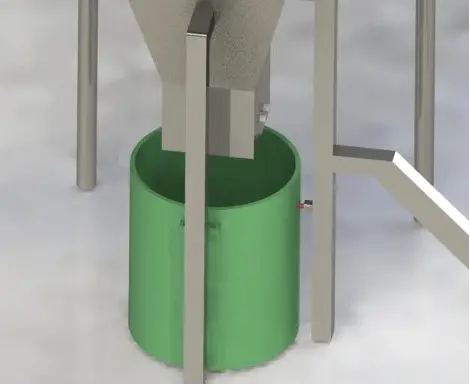

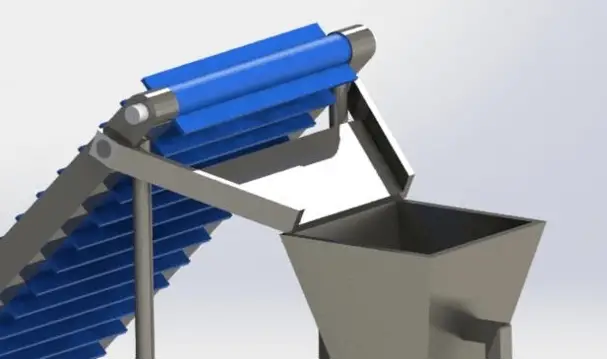

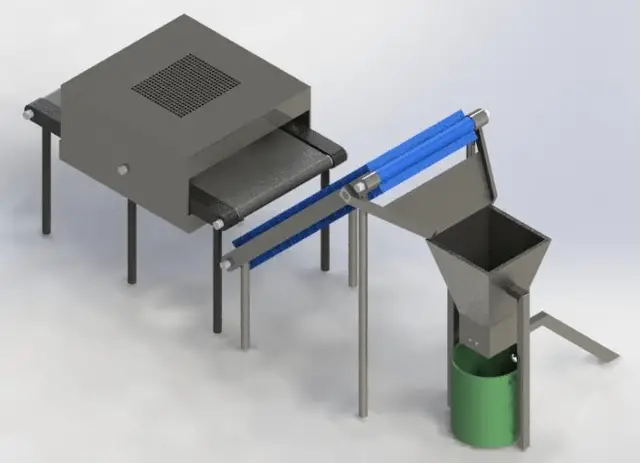

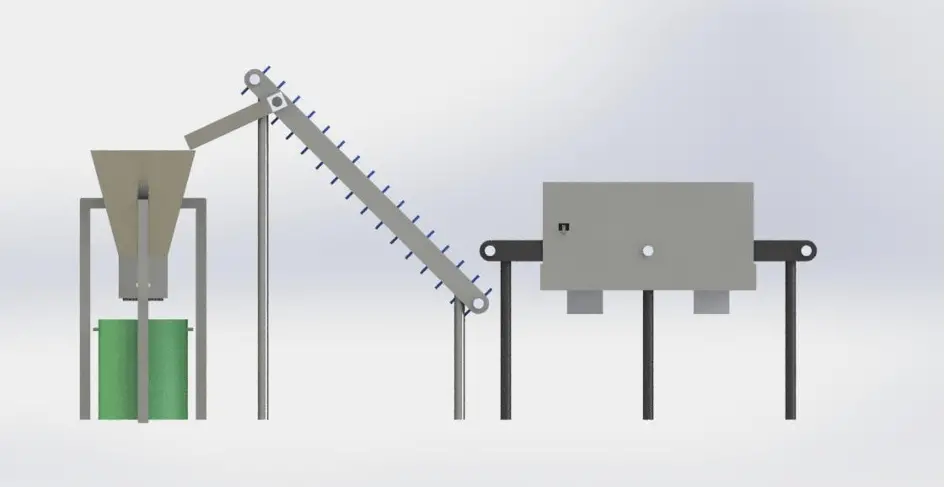

In the following process, the dry bread is to shred into smaller pieces. On top, there is a hopper that collects the dry bread delivered from the heating process. It’s angled walls that go from wide to narrow ensure more space for the bread to rest in. A design for the shredding system is shown below:

A 2-Shaft Shredding System S40 manufactured by UNTHA sits below to do the job of cutting. Before it drops in the box, there will be a replaceable pored screen that is adjustable to the size required.

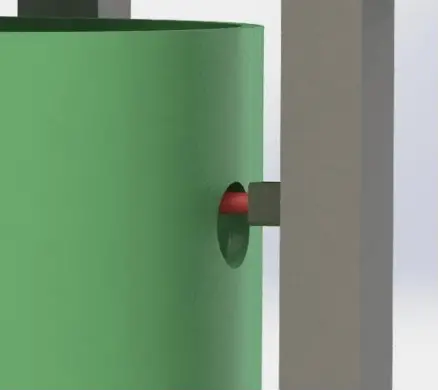

Pieces of the right size drop into a collecting barrel that has a capacitive sensor at the top, this sensor is activated when the right amount of bread is available. After it gets activated, the shredder and the inclined conveyor stop.

One more point to consider is the shaking of the machine that required human interaction to keep it in place. To solve this issue, an extension has been made to the third central leg to give more stability to the machine as it will be fixed to the ground. As (Xanthakos, 2007) points out in his book about “Ground Anchors and Anchored Structures”, Using Wedged Anchors is a suitable solution for this particular application where the machine could face vertical forces resulting in the movement of the machine from its position.

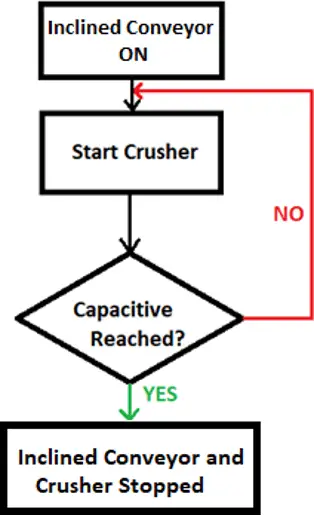

3.4.2 PLC Programming for Cutting System

PLC Flow chart for the Cutting Process:

After the bread has gone through the drying phase, it is transferred onto the cutting process on an inclined conveyor that delivers the bread, the PLC will turn the crusher and the second conveyor on, as soon as the first conveyor starts moving again after the bread is dehydrated. As the shredder crushes the dry bread, a capacitive sensor will be waiting in the collecting barrel to be full, this happens when pieces of crushed bread fill the box and reach the capacitive sensor to become in touch with it. After that point is reached, a signal is sent to the PLC to stop the shredder and the inclined conveyor, then the collecting barrel is taken away into the next process of mixing.

Input/Output List:

| Allocation | Inputs | Allocation | Outputs |

| _IO_EM_DI_04 | Capacitive Sensor | _IO_EM_DO_04 | Inclined Conveyor |

| _IO_EM_DO_05 | Crusher Motor |

3.4.3 Connection of Drying to Cutting

The height of the conveyor in the drying phase must be less than the average human height, to make it easier for the worker to place the bread on it. However, the cutting system should be relatively higher because of the collecting barrel beneath it. To tackle this problem, an inclined conveyor belt will be added in between.

As the first conveyor starts moving again when the bread is fully dehydrated, it drops the bread from the other end. The steps on the inclined conveyor belt will catch the bread as it drops and drives it upwards.

After the bread reaches the top of the inclined conveyor, it will have to drop again into the hopper of the cutting system. The mechanism is shown in Figure 23, where a slider connecting both ends, is cut from the conveyor side allowing the steps on the conveyor to pass without any interaction with it. bread drops on the slider and then down to the hopper.

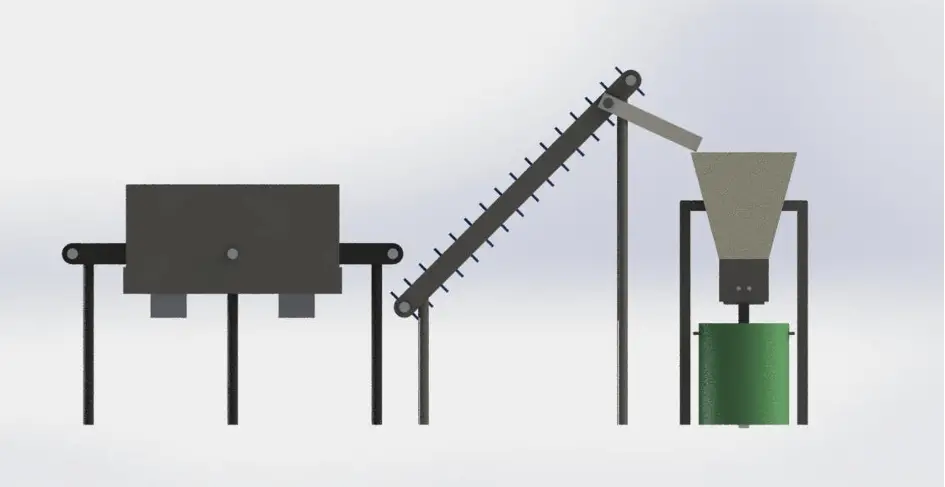

This leaves the full design to be looking like the one shown in Figure 24, for more views of the full design see Appendix 2.

3.5 Mixing

The mixing process is optional and varies depending on the customer demands, therefore, the product that comes out from the previous process is the base and ready to be sold. Since the product might be needed for different uses, which require varying additives to be added to the base product, the mixing process can not be linked to the rest of the process, yet, it will be automated on a separate basis.

3.5.1 Mixing Method Selection

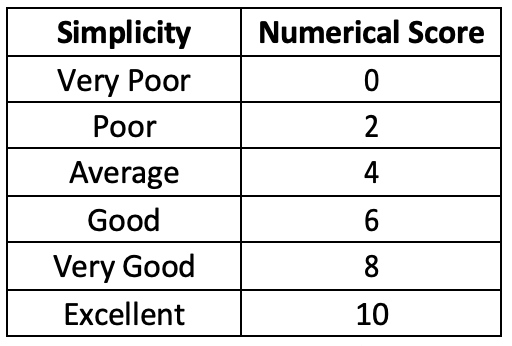

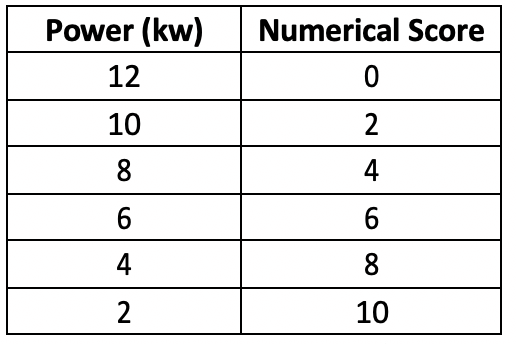

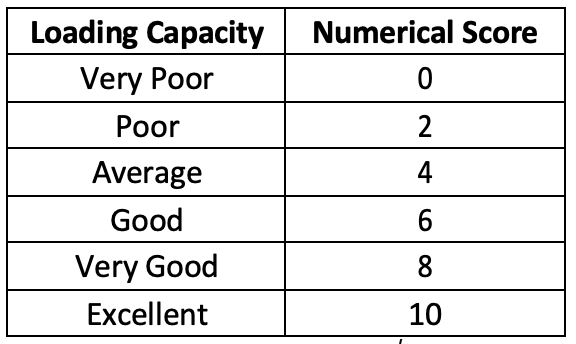

According to the research made earlier, there is two main processes that could be used in this case:

- W-Shape Rotary Double Cone Powder Mixer model GHJ-50W representing the Tumbling mixer (KODI, 2019)

- Animal Poultry Stationary Feed Mixer representing a stationary mixer model 9HWP150 (Casen, 2019).

They are both very similar with minimal differences and a weighted objectives method will be performed to choose the best of both. A factor with more significance over the other has a score of 1, a score of 0.5 when the factor is less significant, and 0.5 when both factors share the same importance.

After performing the weighted objective method, the Rotary Mixer appeared to be the method to achieve a higher score taking into consideration the importance of each factor.

Chapter 4: Results, Discussion, and Evaluation

4.1 Overview

By reaching the results part, now the project can be evaluated concerning the success in achieving the objectives and aims set earlier. The main subjects discussed in this chapter are the automation processes, installing the prototype and reduction of workers, and reduction of the overall time.

4.2 Automation of the Processes and Installing the Prototype

The four processes involved were to be automated, yet after performing the research, not all the processes were applicable for automation. As the sorting remained manual, this is due to the complexity of installing such a system, and using overpriced equipment for performing a simple task seems to be irrational. An appropriate alternative, which includes already present personnel for inspection was found to be more efficient. Therefore, this issue should not affect the overall performance.

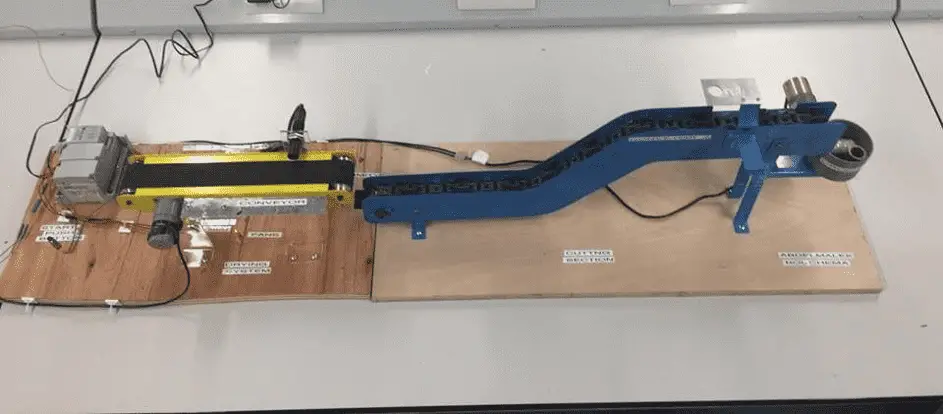

As for the Drying and Cutting processes, a completely automated system would be installed and controlled using a PLC, and they are demonstrated using a prototype that shows the procedures taken in each process. Implementation of this process is done by downloading the written code onto the PLC and connecting it with the parts resembling the actual components.

| Actual Component | Prototype Part |

| Meshed Conveyor | 24V Conveyor |

| Heaters | Red LED |

| Fans | Motors |

| Thermistor | Potentiometer |

| Start Push Button | Start Push Button |

| Proximity Sensor | Inductive Sensor |

A Start Push-Button will be used to start the system and shown below:

A 24V Conveyor will be acting as the actual meshed Conveyor, and it turns on when the start pushbutton is pressed.

While a Red LED represents the Heaters, a Potentiometer will be representing a thermistor for temperature control and the resistance can be manually varied to show how the heaters will react under different cases. For example, when the temperature gets above the required point the heaters will turn off to allow the cabin to cool down and when the temperature is below the required point heaters will turn on, this maintains the correct temperature. Furthermore, it is a more practical way of varying the values of the temperature rather than using an actual thermistor, especially for prototype testing.

An inductive sensor used for proximity sensing will stop the conveyor at the point when the drying cabin is full.

A Green LED will be used to represent the fans, since the fans available in the labs were not of use to the prototype as there will be not enough current to turn them on due to the high resistance provided by them.

As for the cutting part, it is expected to be connected to the drying section using a different type of conveyor that is placed at an angle, and it carries the bread upwards then drops the bread into the hopper of the cutting machine.

A Hopper will be sitting at the end of the second conveyor waiting for the object to drop.

Since this prototype is built only for demonstration and testing of whether the written code works, it will not be performing the actual job of the production line.

A metallic cylindrical object acts as the bread in this prototype.

As for the controlling, An Allen Bradley Micro820 PLC was used for controlling the prototype, and the same code on CCW mentioned in the methodology chapter of the report is used for this prototype with scaled-down values for the timers. It has been successful in performing the tasks expected from it, and a video was recorded to show the components and the mechanism of the system.

The mixing process is automated but not connected to the production line as it works separately; therefore, it is not included in the programming of the PLC.

4.3 Reduction of Overall Time

The overall time taken in the manufacturing of the product is a crucial factor when evaluating the success of the project since it was one of the main constraints the manufacturers were facing. As the sorting method remains the same, no time change is expected to be present.

After performing the appropriate research and having a discussion with the manufacturer, it appeared that the most time-consuming process is the dehydration of the bread. The best performance using the old method takes 6 hours to dehydrate the bread fully, but as mentioned earlier, this requires the presence of sun and wind, but under certain circumstances where these factors are absent it could take up to 24 hours.

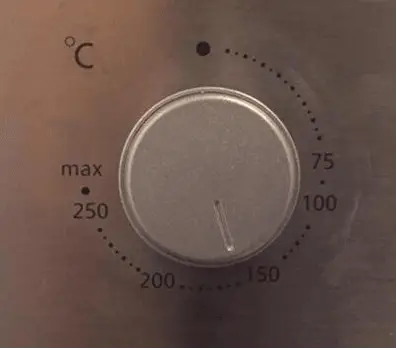

4.3.1 Experimental Results for Drying

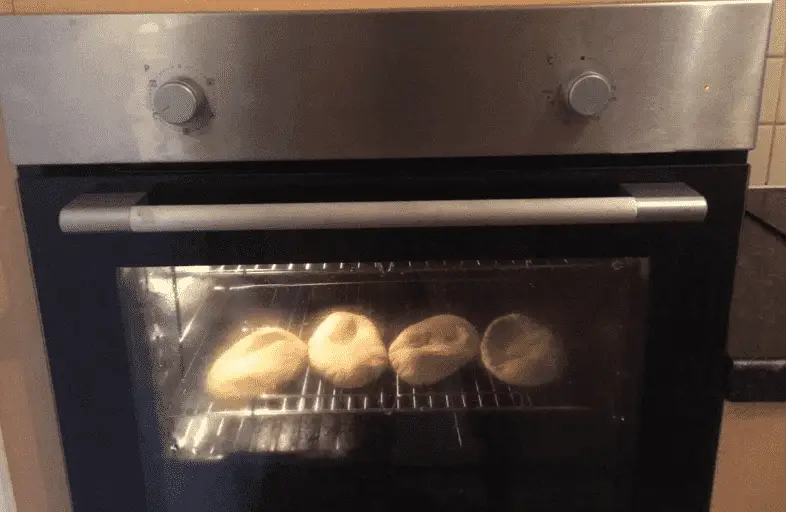

The new proposed design for the drying system should cut down the time taken significantly. To prove this, an experiment was conducted to set the time and temperature taken for the completion of this process. Bread is left in an electrically heated oven that functions in a similar way to the design shown earlier. Electrical coils are the source of heat and fans blow the heated air on it.

For accuracy purposes, the experiment is done 3 times, and the mean is taken. A stopwatch is used to measure the time where it starts at the point where bread is placed in the oven and stopped when the bread is hard and brittle. The bread was checked every 5 minutes to test its state.

| Temperature (C°) | |||

| Time taken (Minutes) | 150 | 250 | 300 |

| Trial 1 | 22.5 | 15.9 | 8.4 |

| Trial 2 | 21.6 | 16.3 | 8.8 |

| Trial 3 | 22.2 | 15.5 | 7.9 |

| Average | 21.8 | 15.9 | 8.4 |

An inversely proportional relationship can be noticed from the results, as the temperature increases, the time taken decreases. A problem was noticed when the bread was left to dry at 300°C, it dries quicker than the rest, but a variation in the bread state has been noticed as

the bread changed to a much darker color, and when it was tested for hardness the inner side of the bread was still moist. The same results were noted at 250°C yet it took more time. The temperature at 150 °C seemed to be the most suitable although it took the longest time to dehydrate yet the inner side was fully dry when tested for hardness.

Here are pictures were taken, showing the state of the bread when it is Fresh, Dehydrated and Burnt respectively.

Cutting and Mixing were not a significant concern when referring to time consumption as it took up to 30 minutes in total to complete both processes, yet the automation of the processes still ended up with a further reduction in time.

Starting with the new cutting system, the 2-Shaft Shredding System S40 used, has a throughput of 15,000 kg/h, which means that it produces 15,000 kg of shredded bread in a duration of an hour. Since the product is sold in 20 kg bags, the time taken to cut 20 kg of dry bread is calculated below:

𝟏𝟓, 𝟎𝟎𝟎 ∗ 𝒙 = 𝟐𝟎 ∗ 𝟏

𝒙= 𝟐𝟎/𝟏𝟓𝟎𝟎𝟎

𝒙 = 𝟎. 𝟎𝟎𝟏𝟑𝟑 𝒉𝒐𝒖𝒓𝒔

𝟔𝟎 ∗ 𝒙 = 𝟎. 𝟎𝟖 𝒎𝒊𝒏𝒖𝒕𝒆𝒔

𝟑𝟔𝟎𝟎 ∗ 𝒙 = 𝟒. 𝟖 𝒔𝒆𝒄𝒐𝒏𝒅𝒔

As for the mixing part, if the “W-shape Rotary Double Cone Powder Mixer” model “GHJ-50W” is installed, then it would take from 4-8 minutes as mentioned in the description of the product by the seller, an average of 6 minutes will be used for calculation.

Adding up the total time taken for all the processes:

𝟔+𝟎.𝟎𝟖 +𝟐𝟏.𝟖 =𝟐𝟕.𝟖𝟖𝒎𝒊𝒏𝒖𝒕𝒆𝒔

4.4 Reduction of Workers

In both cases the old and the new system, the number of workers involved in production will depend on the workload. However, the automation of the system should reduce the number of workers needed since the installed machines will handle several functions eliminating the need for a human. After the discussion with the manufacturer, it came into sight that the number of workers ranges between 10-25 people, tasks listed below:

- Inspection of the collected bread that arrives at the site.

- Spreading the bread in open air then collecting it when it is completely dry.

- Fixing the machine in place and rotating the shaft of the shredder.

- Pouring the product in the mixing barrel and mixing it manually

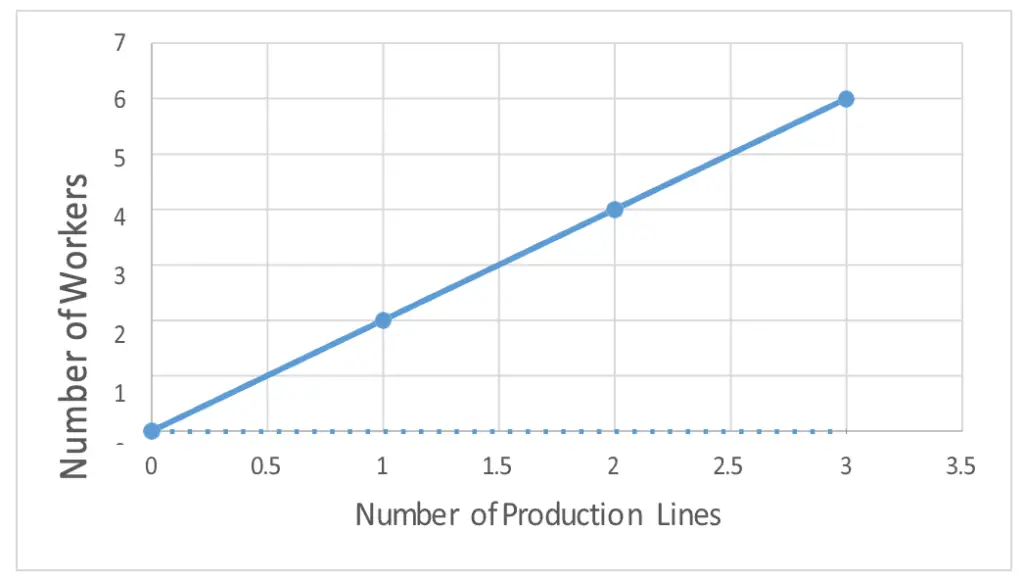

Taking each of the tasks individually, an evaluation of success can be conducted. Starting with bread inspection, as mentioned earlier it will remain the same since the process remains manual and a person will be inspecting and placing the bread of the drying conveyor of the drying phase simultaneously. At the point where the bread is placed on the conveyor, there will be no need for human interaction up to the point where the point the bread is fully dried and crushed. After that point, a worker will be required to deliver the product to the mixing processes for the addition of additives. In conclusion, workers needed after the automation is reduced to two essentially and increases as the production increases. Another point to consider is that this case is if the factory is operated using a single production line. If the automated production line is duplicated this means that more workers will be needed to operate them.

5.0 Recommendations for Further Work for Automated Production Line

The report was concerning only one line of products that can produce 20 kg of the product in a duration of 27.88 minutes. It is expected that sometimes the workload will be more than expected; thus, having another production line will be of help in such cases.

Moreover, the sorting and mixing processes to be further automated. For the mixing process, the addition of more components that work as a connection between cutting and mixing, together with a Human Machine Interface (HMI) installed for a worker to control the additives being added to the product, should complete the automation of the mixing process.

6.0 Conclusion

To conclude, the project has covered the main objectives mentioned at the beginning of the report:

- As required by the manufacturer, an actual design of the production line has been included and tested using a prototype showing the procedures taken by the automated processes.

- The main aspects like the time taken and workers needed after automation have also been discussed, and great progress is expected in both cases if the automation was installed.

- The research was completed regarding the possible automated processes that could replace the old methods together with the components needed for these processes. A weighted objectives method has been used in cases where a choice must be taken between different methods or machines.

The report has been successful in most aspects, however, after proceeding more into the project, it became clear into view that some of the aspects mentioned earlier were either not preferable to do or might not be of any advantage to the factory.

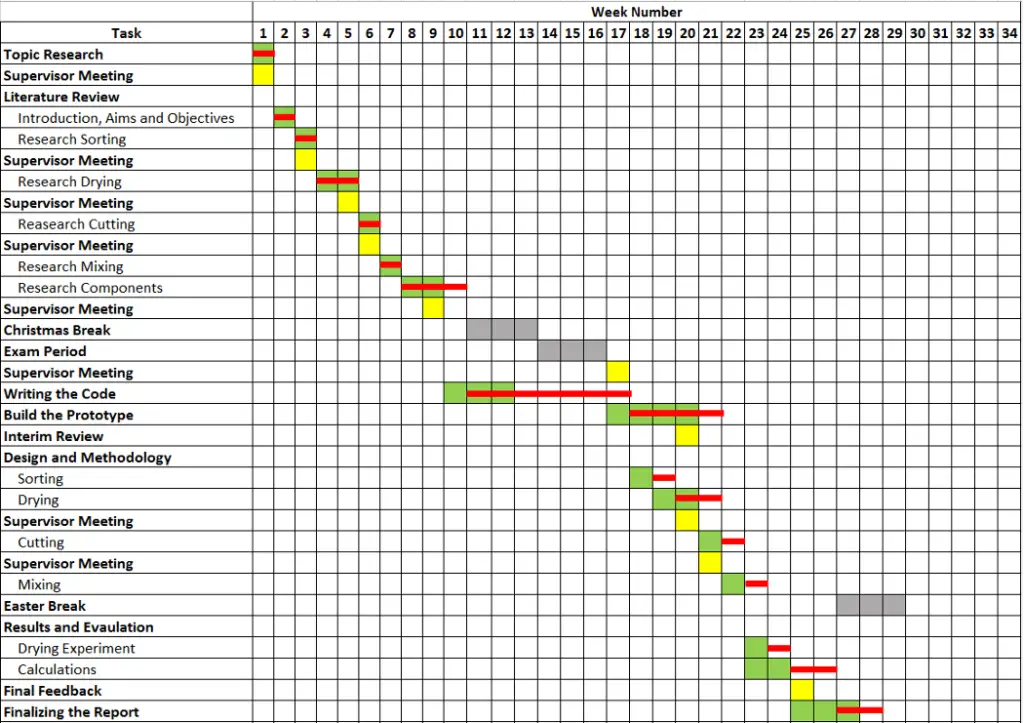

7.0 Project Management of Designing an Automated Production Line

Green Boxes illustrate the expected time taken for each task to finish, while red lines are the actual times taken. Yellow Boxes represent meetings and Grey boxes represent breaks and exams. Week 1 starts at the 1st of October 2018.

It could be noticed the project was expected to be finished by Week 27. However, it was slightly delayed due to several challenges that came up during the project.

There was a plan to work on the project during the Christmas break, however, due to traveling, the research part of the report has taken longer than expected as it was stopped until after the exam period as shown the Gantt Chart.

As for building the prototype, some components that were planned to be used were not available in the lab. This cause the building to finish later than expected as it took further time looking for alternatives that could be used.

Moreover, In Chapter 2: Methodology and Design, an issue with the design of the heating cabin came up. Thus, changes in the design were performed to suit the application.

This has delayed the project by nearly two weeks finishing between Week 28 and 29.

Ethics

As stated by (Royal Academy of Engineering and the Engineering Council, 2005), engineers at any level, should always have ethical considerations. They are divided into four main elements, as listed below:

– Respect for life, law, the environment, and public good

As mentioned earlier in the introduction, the ultimate aim of the organization is to make use of the waste bread for the sake of helping the poor in their education. As well as, bringing attention to the recycling mentality as it does not have much popularity in the Jordanian culture.

– Honesty and integrity

This is a crucial element as information, figures, tables collected, and software used throughout the report are all referenced for originality. Information collected is presented without any falsification. Discussion of results was honest and shown to prove success in each case.

– Accuracy and rigor

It is noted in parts of the report, that some values were lacking absolute accuracy due to the limitations of resources, and some assumptions were taken as shown in Section 3.3.1 calculating the cabin loading area.

– Leadership and communication

Appendices

Appendix 1: The Full PLC code written on CCW for Automated Production Line

Appendix 2: Full views for the actual design of Automated Production Line

Appendix 3: Bread Dehydration Experiment with Automated Production Line

Appendix 4: Automated Production Line Prototype Full View

References

- ABDULLAH, M. Z., 2000. QUALITY INSPECTION OF BAKERY PRODUCTS USING A COLOR-BASED MACHINE VISION SYSTEM. Journal of Food Quality, 23(1), pp. 39-50.

- Adomaitis, M. A. F. B. R. C. E. F. M. F. S. H. C. H. K. H. S. K. K. a. L. C., 2018. U.S. Patent Application.

- Continuous conveyor belt for food heating device.

- Al-Tuwaysi, B., 2013. Al-Ghad Newspaper. [Online]

Available at: http://www.ammanxchange.com/art.php?id=8f585ce1a7a02b815c8b27bdff881d531092ce73 - Anuja Bhargava, A. B., 2018. Journal of King Saud University – Computer and Information Sciences.

- Fruits and vegetables quality evaluation using computer vision: A review. Arduino, 2019. ARDUINO UNO REV3. [Online]

- Available at: https://store.arduino.cc/arduino-uno-rev3

- Arduino, 2019. Introduction, What is Arduino?. [Online] Available at: https://www.arduino.cc/en/guide/introduction

- Automation24, 2019. Diffuse reflection sensor Automation24 OGT109 – BasicLine. [Online]

Available at: https://www.automation24.co.uk/diffuse-reflection-sensor-automation24-ogt109- basicline?previewPriceListId=1&refID=adwords_shopping_UK&gclid=CjwKCAjwzPXlBRAjEiwAj_XTER GAGnsFtdfZksvZehNWQ0DyJV53REzAD9JfdGz440Hm2tRaZez61BoCwWEQAvD_BwE - Ayensu, A., 1997. Solar energy 59. Dehydration of food crops using a solar dryer with convective heat flow.

- Bala, B. K., 2016. Drying and Storage of Cereal Grains. 2 ed. s.l.:s.n.

- Bartelt, T. L. M., 2006. Industrial control electronics. Australia: Thomson Delmar Learning.

- Baxter, L. K., 1996. Capacitive sensors. New York: IEEE industrial electronics society.

- Bhesh Bhandari, M. Z., 2013. Handbook of Food Powders. s.l.:Elsevier Science & Technology.

- Bolton, W., 2011. Programmable Logic Controllers. In: 4 ed. s.l.:Elsevier, pp. 3-4.

- BSSA, 2019. BRITISH STAINLESS STEEL ASSOCIATION. [Online] Available at: https://www.bssa.org.uk/topics.php?article=103#top

- Casen, 2019. CE ISO production small vertical animal poultry stationary feed mixer for sale with one year warranty. [Online]

Available at: https://www.alibaba.com/product-detail/CE-ISO-production-small-vertical- animal_60623600969.html?spm=a2700.7724857.normalList.81.1bdd9d124bvHQC - Cheng-Jin Du, D.-W. S., 2004. Trends in Food Science & Technology. Recent developments in the applications of image processing techniques for food quality evaluation.

- Dunning, G., 2006. In: Introduction to programmable logic controllers. Clifton Park, NY: Thomson/Delmar Learning, pp. 14-15.

- Espares, 2019. Fan Oven Motor. [Online]

Available at: https://www.espares.co.uk/product/es1670942/fan-oven- motor?pageNumber=1&PartTypeId=1596&ManufacturerId=880 - Fellows, P. J., 2009. Food Processing Technology. 3 ed. Boca Raton, Fla: Elsevier Science & Technology.

- Gupta, A. K., 2011. Industrial automation and robotics. Bangalore, India: University Science Press. Hegbom, T., 1997. Integrating electrical heating elements in appliance design. New York: Marcel Dekker.

- Hern, A., 2015. Artificial intelligence (AI). [Online]

Available at: https://www.theguardian.com/global/2015/may/13/baidu-minwa-supercomputer- better-than-humans-recognising-images - Ho-Hsien Chen, C. E. H. T.-C. H., 2005. A study of the drying effect on lemon slices. Solar Energy, 78(1), p. 97–103.

- Ibrahim, D., 2002. Microcontroller-based temperature monitoring and control. Oxford: Newnes. IFM, 2019. Capacitive Sensor KI6000. [Online]

- Available at: https://www.ifm.com/gb/en/product/KI6000

- James G. Brennan, A. S. G. J. G. B., 2012. Food Processing Handbook. 2 ed. Weinheim, Germany: John Wiley & Sons, Incorporated.

- Janata, J., 2010. In: Principles of Chemical Sensors. Dordrecht: Springer, pp. 54-56. Juds, S. M., 1988. Photoelectric sensors and controls. New York: Dekker.

- Kerr, C., 2017. PITTA-FUL CBBC presenter Ortis Deley slams Surrey cafe for serving his 18-month-old MOULDY pitta bread. [Online]

Available at: https://www.thesun.co.uk/news/4715120/cbbc-ortis-deley-mouldy-pitta-pistachios- surrey/ - KODI, 2019. W Shape Rotary Double Cone Powder Mixer. [Online]

Available at: https://www.alibaba.com/product-detail/W-Shape-Rotary-Double-Cone- Powder_60758985962.html?spm=a2700.7724857.normalList.11.f1e5d3f88UEzXj&s=p - Lewicki, P. P., 2006. Design of hot air. Trends in Food Science & Technology, pp. 153-163. Lorcan, 2018. What is a Fan Oven?. [Online]

- Available at: https://www.shipitappliances.com/ovens/what-is-a-fan-oven/

Maoqiang Jiang, Y. Z. G. L. J. Z., 2011. Enhancing mixing of particles by baffles in a rotating drum - mixer. Particuology, 9(3).

Minguez-Mosquera, M., 1993. Lipoxygenase activity during pepper ripening and processing of - paprika. Phytochemistry, 32(5), p. 645–648.

Moreira, R. G., 2001. Impingement drying of foods using hot air and superheated steam. Journal of - Food Engineering, 49(4), pp. 291-295.

Mortaza Aghbashlo *, H. M. ,. S. R. A. M., 2013. Renewable and Sustainable Energy Reviews. A - review on exergy analysis of drying processes and systems.

- Mortaza Aghbashlo *, M. H. K. A. A., 2009. Journal of Food Engineering. Performance analysis of drying of carrot slices in a semi-industrial continuous band layer.

- Naewbanij, M. & Thepent, V., 1991. Batch and continuous drying. 15 11.

Nawrocki, W., 2005. In: Measurement Systems and Sensors. s.l.:Artech House, pp. 23-28. - Nieuwenhuijzen, N. H. v., 2008. Water Content or Water Activity: What Rules Crispy Behavior in Bread Crust?. Journal of Agricultural and Food Chemistry, 56(15), pp. 6432-6438.

- OMEGA, E., 2019. Omega. [Online]

Available at: https://www.omega.co.uk/temperature/z/thermocouple-RTD.html#pimenu [Accessed January 2019]. - Paul, E. L., 2004. Handbook of industrial mixing. Hoboken, N.J.: Wiley-Interscience. Platat, C., 2015. Production of functional pita bread using date seed powder. [Online]

- Available at: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4573111/

- Rockwell Automation, 2013. Rockwell Automation. [Online]

Available at: https://literature.rockwellautomation.com/idc/groups/literature/documents/pp/2080- pp004_-en-p.pdf - Rota, F., 2015. U.S. Patent Application. Two-Shaft Industrial Shredder.

- RUPERTI, Y., 2019. Perfect Homemade Pita Bread Recipe. [Online]

Available at: https://www.seriouseats.com/2015/08/how-to-make-perfect-homemade-pita- bread.html - S. Öztekiṅ , A. B. Y. S., 1999. Crop drying programme in Turkey. Renewable Energy, 16(1-4), pp. 789- 794.

- Solutions, C. E., 2019. PacTitan. [Online]

Available at: http://cambridge-es.com/products/straight-line-positive-drive-belts/pactitan - Stephanie Clark, S. J. B. L., 2004. Food processing. 2 ed. Chichester, West Sussex, UK: Wiley Blackwell. Sunol, A. K., 1996. Batch processing systems engineering. New York: Springer Verlag.

- SYPSAL, 2019. Inclined Belt Conveyor. [Online]

Available at: https://www.syspal.com/inclined-belt-conveyor.html#review-form - Udayashankara, V., 2013. 8051 microcontroller. New Delhi: Tata McGraw-Hill.

- UNTHA, 2019. UNTHA S40. [Online]

Available at: https://www.untha.com/en/shredders/industrial-shredders/s40_p232 [Accessed March 2019]. - Unversity of Sunderland, 2018. Student’s business is best thing since sliced bread. [Online]

Available at: https://www.sunderland.ac.uk/more/news/story/students-business-is-best-thing-since- sliced-bread-406 - Xanthakos, P. P., 2007. Ground anchors and anchored structures. Norwich, NY: Knovel.

- Zaid Obeidat, M. O. A. O., 2015. European Journal of Business and Management. Wasteful Consumption of Bread: Its Levels, Sources, and Possible, 7(15).

Credit: A Final year project on “Designing an Automated Production Line for Manual Operating Recycling Plant” was completed by Abdelmalek Bouchema under the supervision of Mrs. Sue Oakesfrom from the University of Sunderland England, United Kingdome.

Leave a Reply