The belts or ropes are used to transmit power from one shaft to another by means of pulleys that rotate at the same speed or at different speeds. The material used for belts and ropes must be strong, flexible, and durable. It must have a high coefficient of friction. Let us discuss the coefficient of friction between belt and pulley.

The coefficient of friction between the belt and the pulley depends upon the following factors:

- The material of the belt

- The material of the pulley

- The slip of the belt

- The speed of the belt

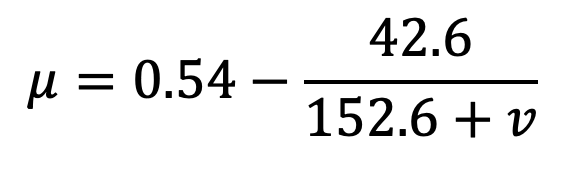

According to the Center of Gravity. Barth, the coefficient of friction (μ) for oak-tanned leather belts on the cast iron pulley, at the point of slipping, is given by the following relation, i.e.

where v = Speed of the belt in metres per minute.

The following table shows the values of coefficient of friction for various materials of belt and pulley.

Coefficient Of Friction Between Belt And Pulley

| Belt material | Pulley material | ||||||

| Cast iron, steel (Dry) | Cast iron, steel (wet) | Cast iron, steel (Greasy) | Wood | Compressed paper | Leather face | Rubber face | |

| 1. Leather oak tanned | 0.25 | 0.2 | 0.15 | 0.3 | 0.33 | 0.38 | 0.4 |

| 2. Leather chrome tanned | 0.35 | 0.32 | 0.22 | 0.4 | 0.45 | 0.48 | 0.5 |

| 3. Convass-stitched | 0.2 | 0.15 | 0.12 | 0.23 | 0.25 | 0.27 | 0.3 |

| 4. Cotton woven | 0.22 | 0.15 | 0.12 | 0.25 | 0.28 | 0.27 | 0.3 |

| 5. Rubber | 0.3 | 0.18 | – | 0.32 | 0.35 | 0.4 | 0.42 |

| 6. Balata | 0.32 | 0.2 | – | 0.35 | 0.38 | 0.4 | 0.42 |

Standard Belt Thicknesses and Widths

The standard flat belt thicknesses are 5, 6.5, 8, 10 and 12 mm. The preferred values of thicknesses are as follows:

- 5 mm for nominal belt widths of 35 to 63 mm,

- b) 6.5 mm for nominal belt widths of 50 to 140 mm,

- 8 mm for nominal belt widths of 90 to 224 mm,

- 10 mm for nominal belt widths of 125 to 400 mm, and (e) 12 mm for nominal belt widths of 250 to 600 mm.

The standard values of nominal belt widths are in R10 series, starting from 25 mm upto 63 mm and in R 20 series starting from 71 mm up to 600 mm. Thus, the standard widths will be 25, 32, 40, 50, 63, 71, 80, 90, 100, 112, 125, 140, 160, 180, 200, 224, 250, 280, 315, 355, 400, 450, 500, 560 and 600 mm.

Leave a Reply