Hydraulic machines are defined as those machines which convert either hydraulic energy (energy possessed by water) into mechanical energy (which is further converted into electrical energy ) or mechanical energy into hydraulic energy. The hydraulic machines, which convert the hydraulic energy into mechanical energy, are called turbines while the hydraulic machines which convert the mechanical energy into hydraulic energy are called pumps. We discussed different types of Hydraulic turbines in the previous article. To run these Turbines, there are certain Characteristic curves are used. From the Theoretical point of view, we can use certain of these Characteristic curves of Hydraulic Turbines to determine the exact behaviour and performance under different working conditions.

Characteristic curves of a hydraulic turbine are the curves, with the help of which the exact behaviour and performance of the turbine under different working conditions, can be known. These curves are plotted from the results of the tests performed on the turbine under different working conditions.

The important parameters which are varied during a test on a turbine are

- Speed (N)

- Head (H)

- Discharge (Q)

- Power (P)

- Overall efficiency (ηo)

- Gate opening

Out of the above six parameters, three parameters namely speed (N), head (H) and discharge (Q) are

independent parameters.

Out of the three independent parameters, speed (N), head (H) and discharge (Q), one of the parameters is kept constant let us say head (H) and the variation of the other four parameters with respect to any one of the remaining two independent variables (say N and Q) are plotted and various curves are obtained. These curves are called characteristic curves.

The following are the important characteristic curves of a turbine.

- Main Characteristic Curves or Constant Head Curves

- Operating Characteristic Curves or Constant Speed Curves

- Muschel Curves or Constant Efficiency Curves

1. Main Characteristic Curves or Constant Head Curves

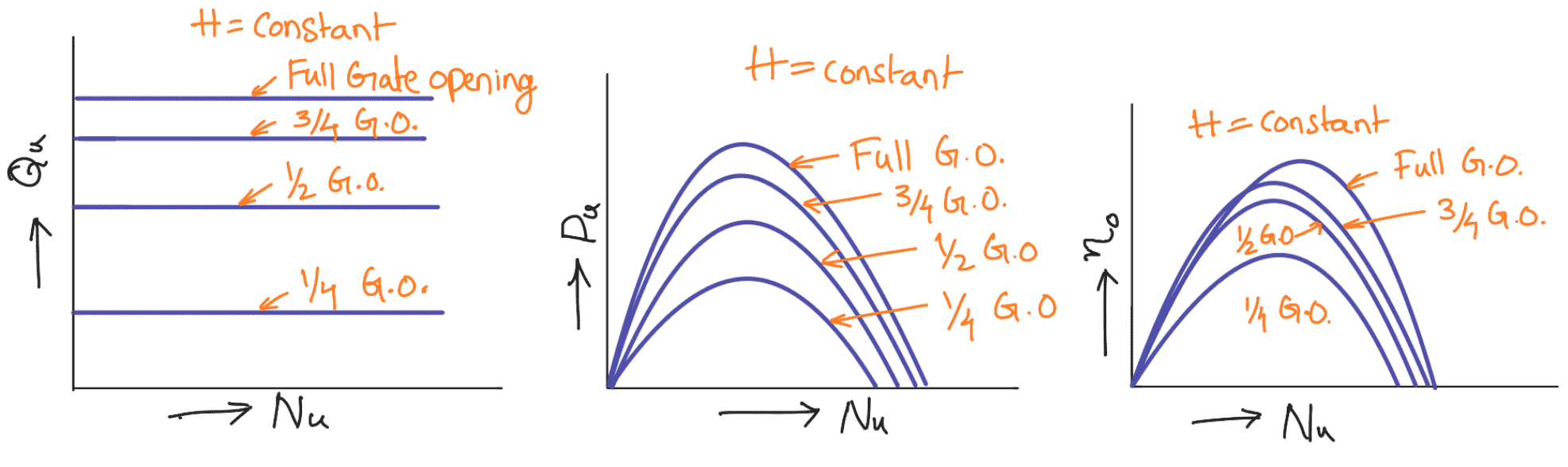

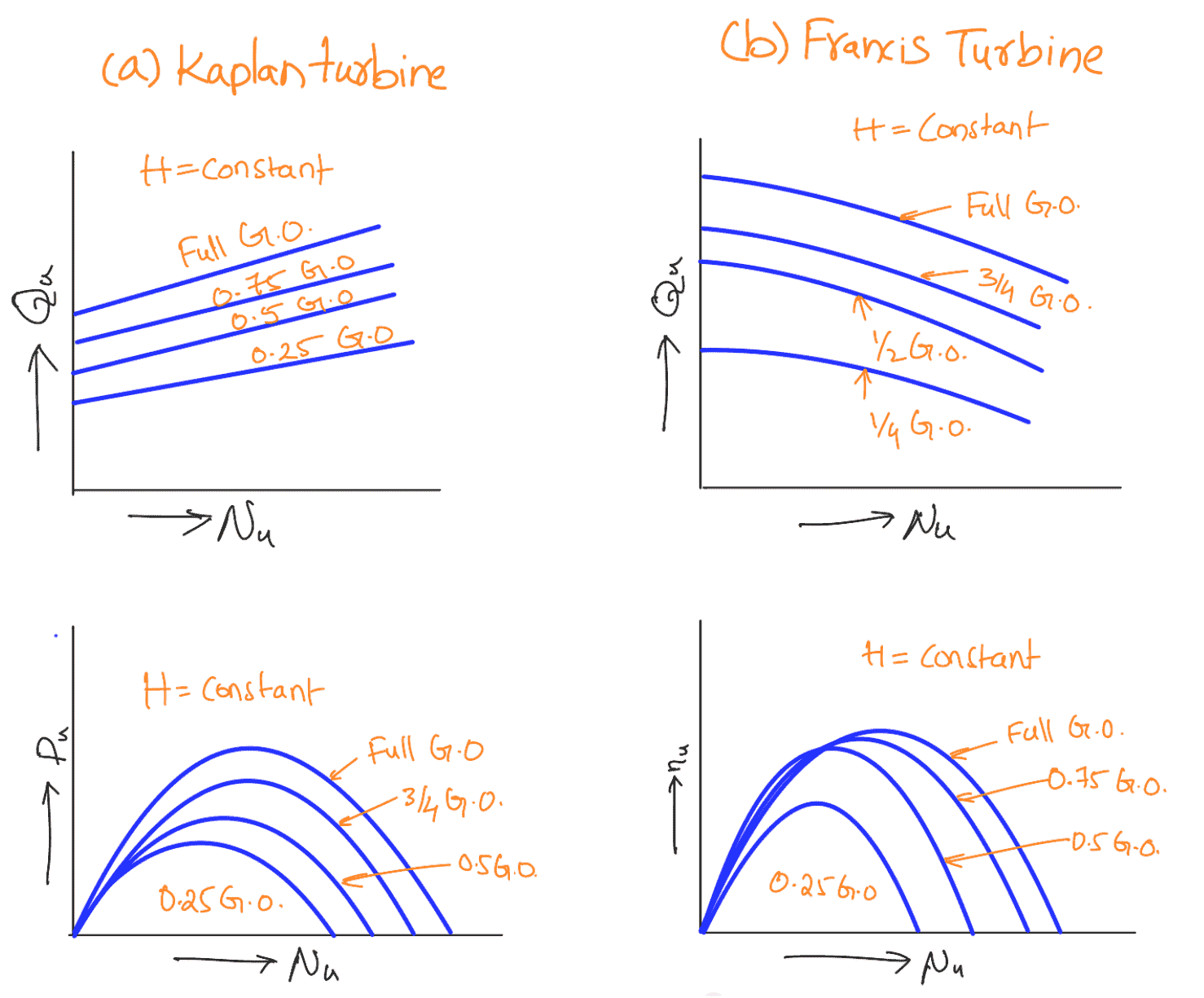

Main characteristic curves are obtained by maintaining a constant head and a constant gate opening (G.O.) on the turbine. The speed of the turbine is varied by changing the load on the turbine. For each value of the speed, the corresponding values of the power (P) and discharge (Q) are obtained. Then the overall efficiency (ηo) for each value of the speed is calculated. From these readings, the values of unit speed (Nu), unit power (Pu) and unit discharge (Qu) are determined. Taking Nu as abscissa, the values of Qu, Pu, P and ηo are plotted as shown in the following graphs.

By changing the gate opening, the values of Qu, Pu, and ηo and Nu are determined and taking Nu as abscissa, the values of Qu, Pu, and ηo are plotted.

The following graph shows the main characteristic curves for the Pelton wheel.

The following graph shows the main characteristic curves for reaction (Francis and Kaplan) turbines.

2. Operating Characteristic Curves or Constant Speed Curves

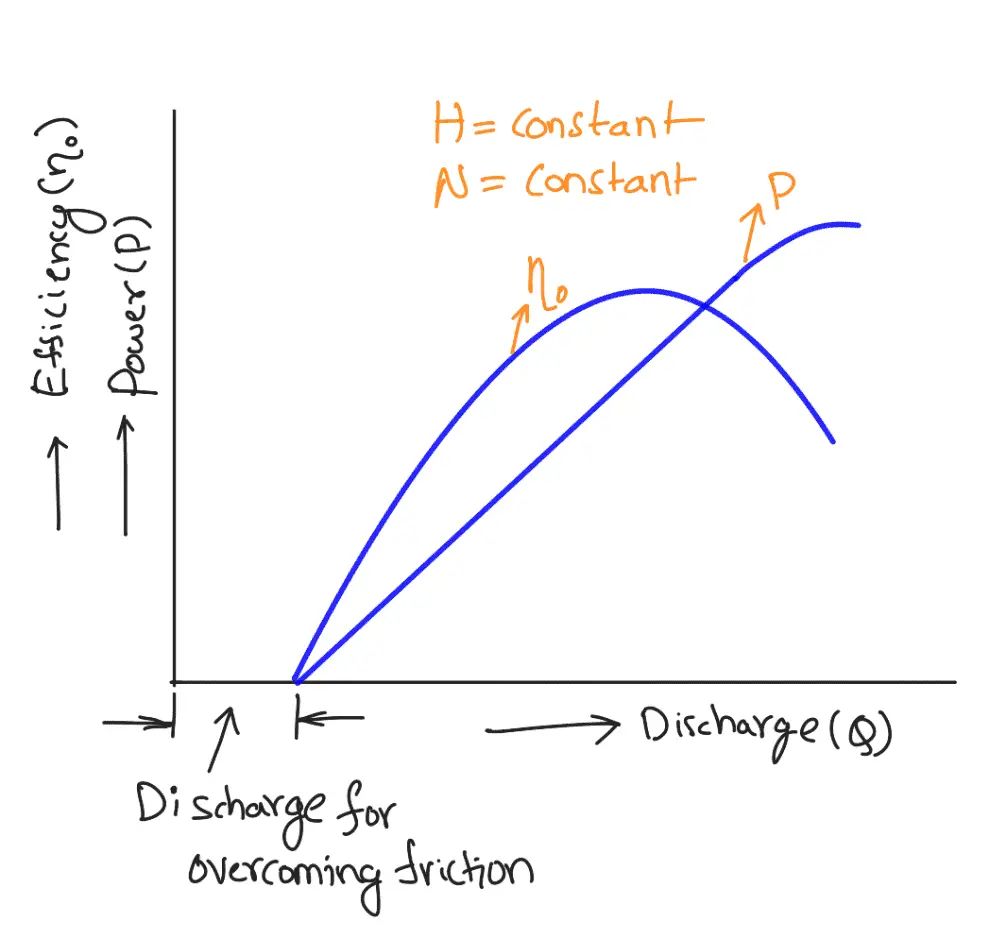

Operating characteristic curves are plotted when the speed on the turbine is constant. In the case of turbines, the head is generally constant. As mentioned above, there are three independent parameters namely N, H and Q. For operating characteristics, N and H are constant and hence the variation of power and efficiency with respect to discharge are plotted. The power curve for turbines shall not pass through the origin because a certain amount of discharge is needed to produce power to overcome initial friction.

Hence the power and efficiency curves will be slightly away from the origin on the x-axis, as to overcome initial friction certain amount of discharge will be required. The following graph shows the variation in power and efficiency with respect to discharge.

3. Constant Efficiency Curves or Muschel Curves or Iso-Efficiency Curves

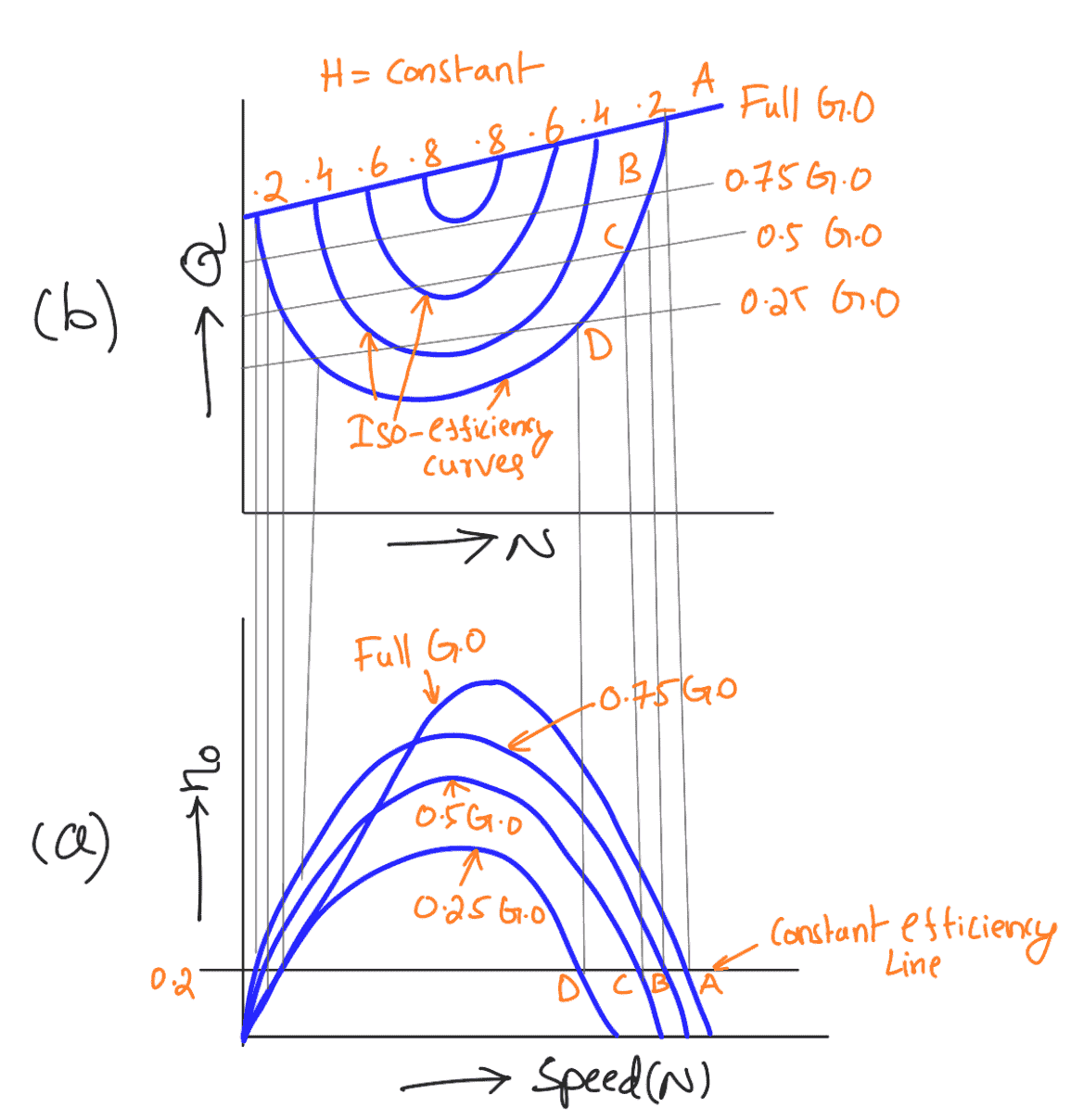

These curves are obtained from the speed vs. efficiency and speed vs. discharge curves for different gate openings. For a given efficiency from the Nu vs. ηo curves, there are two speeds. From the Nu vs. Qu curves, corresponding to two values of speeds there are two values of discharge.

Hence for a given efficiency, there are two values of discharge for a particular gate opening. This means for a given efficiency there are two values of speeds and two values of the discharge for a given gate opening. If the efficiency is maximum there is only one value. These two values of speed and two values of discharge corresponding to a particular gate opening are plotted as shown in graph b (the upper plot). The procedure is repeated for different gate openings and the curves Q vs. N are plotted. The points having the same efficiencies are joined. The curves having the same efficiency are called iso-efficiency curves. These curves are helpful for determining the zone of constant efficiency and for predicting the performance of the turbine at various efficiencies.

For plotting the iso-efficiency curves, horizontal lines representing the same efficiency are drawn on the ηo ~ speed curves. The points at which these lines cut the efficiency curves at various gates openings are transferred to the corresponding Q ~ speed curves. The points having the same efficiency are then joined by a smooth curve. These smooth curves represent the iso-efficiency curve.

These Characteristic curves of Hydraulic Turbines help us determine the exact behaviour and performance under different working conditions. Let us know what you think about this article in the comment section below.

Leave a Reply