The hydraulic machines, which convert the hydraulic energy into mechanical energy, are called turbines while the hydraulic machines which convert mechanical energy into hydraulic energy are called pumps. Hydraulic energy is in the form of pressure energy. If the mechanical energy is converted into pressure energy by means of centrifugal force acting on the fluid, the hydraulic machine is called a centrifugal pump. We discussed How to calculate Work Done, Heads & Efficiencies and Minimum starting speed of Centrifugal Pump. To run these Centrifugal Pumps, there are certain Characteristic curves are used. From the Theoretical point of view, we can use certain of these Characteristic curves of Centrifugal Pumps to determine the exact behaviour and performance under different working conditions.

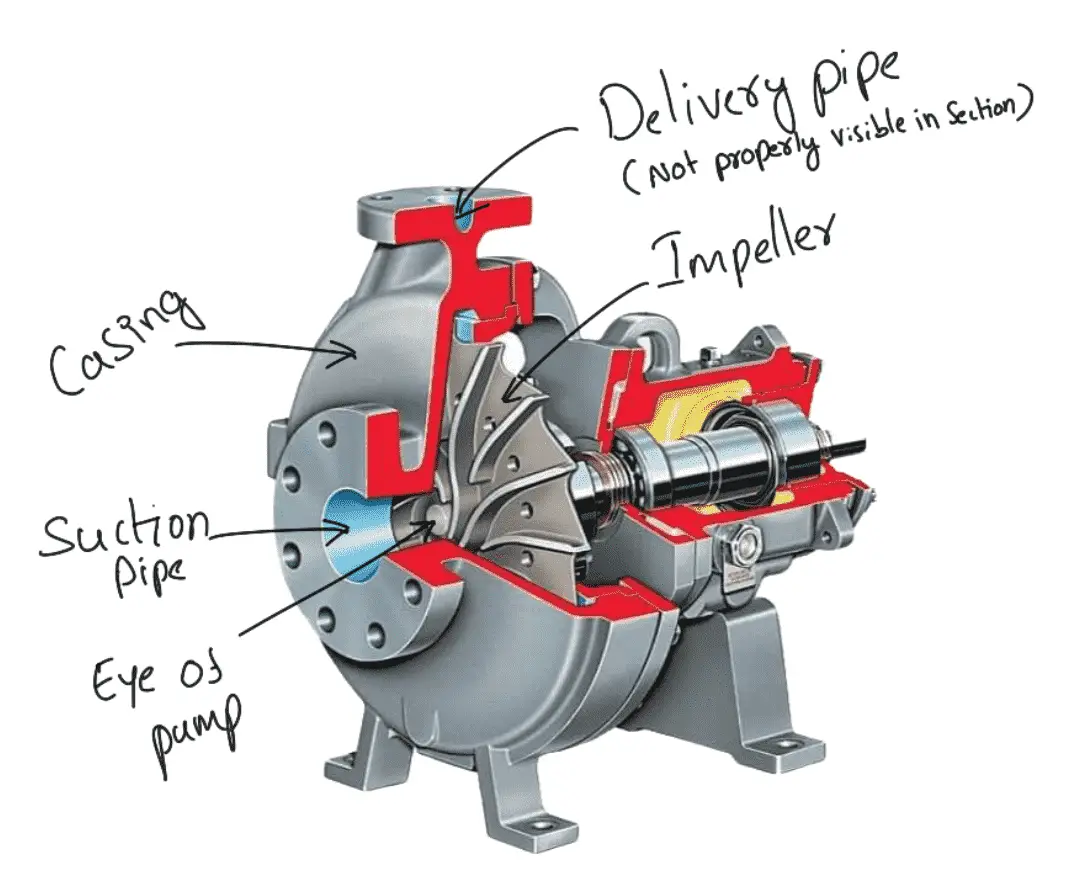

Centrifugal Pump

As we mentioned Centrifugal Pump converts the mechanical energy into pressure energy by means of centrifugal force acting on the fluid.

- The centrifugal pump acts as a reverse of an inward radial flow reaction turbine.

- This means that the flow in centrifugal pumps is in the radial outward directions.

- The centrifugal pump works on the principle of forced vortex flow.

- This means that when a certain mass of liquid is rotated by an external torque, the rise in pressure head of the rotating liquid takes place.

- The rise in pressure head at any point of the rotating liquid is proportional to the square of the tangential velocity of the liquid at that point.

- Thus at the outlet of the impeller, where the radius is more, the rise in pressure head will be more and the liquid will be discharged at the outlet with a high-pressure head.

- Due to this high-pressure head, the liquid can be lifted to a high level.

Characteristic Curves of Centrifugal Pumps

Characteristic curves of centrifugal pumps are defined as those curves which are plotted from the results of a number of tests on the centrifugal pump. These curves are necessary to predict the behaviour and performance of the pump when the pump is working under different flow rates, heads and speeds. The following are the important characteristic curves for pumps :

- Main characteristic curves,

- Operating characteristic curves, and

- Constant efficiency or Muschel curves.

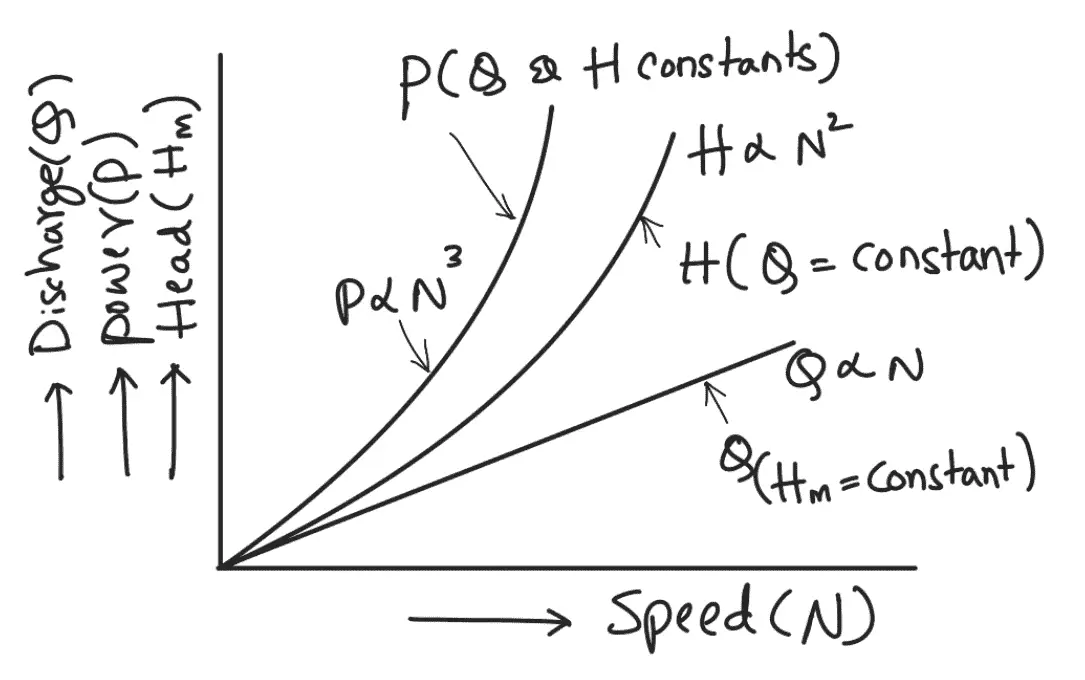

1. Main Characteristic Curves

The main characteristic curves of a centrifugal pump consisting of a variation of the head (manometric head, Hm), power and discharge with respect to speed. For plotting curves of manometric head versus speed, discharge is kept constant. For plotting curves of discharge versus speed, the manometric head (Hm) is kept constant. And for plotting curves of power versus speed, the manometric head and discharge are kept constant. The following graph shows the main characteristic curves of a pump.

For plotting the graph of Hm versus speed (N), the discharge is kept constant.

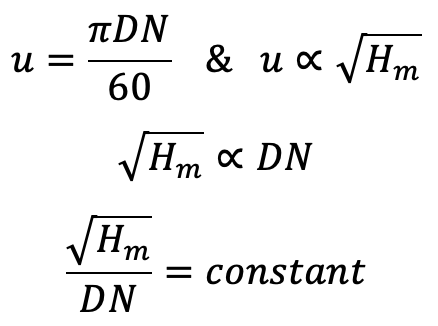

From the tangent velocity equation,

From the above equation, it is clear that √Hm /DN is a constant or Hm ∝ N2.

This means that the head developed by a pump is proportional to N2. Hence the curve of Hm v/s N is a parabolic curve as shown in the above graph.

We know the power of the pump from the previous article, it is clear that P/D5N3 is a constant.

Hence P ∝ N. This means that the curve P v/s N is a cubic curve as shown in the above graph.

Also from the previous article, we know

This means Q ∝ N for a given pump. Hence the curve Q v/s N is a straight line as shown in the above graph.

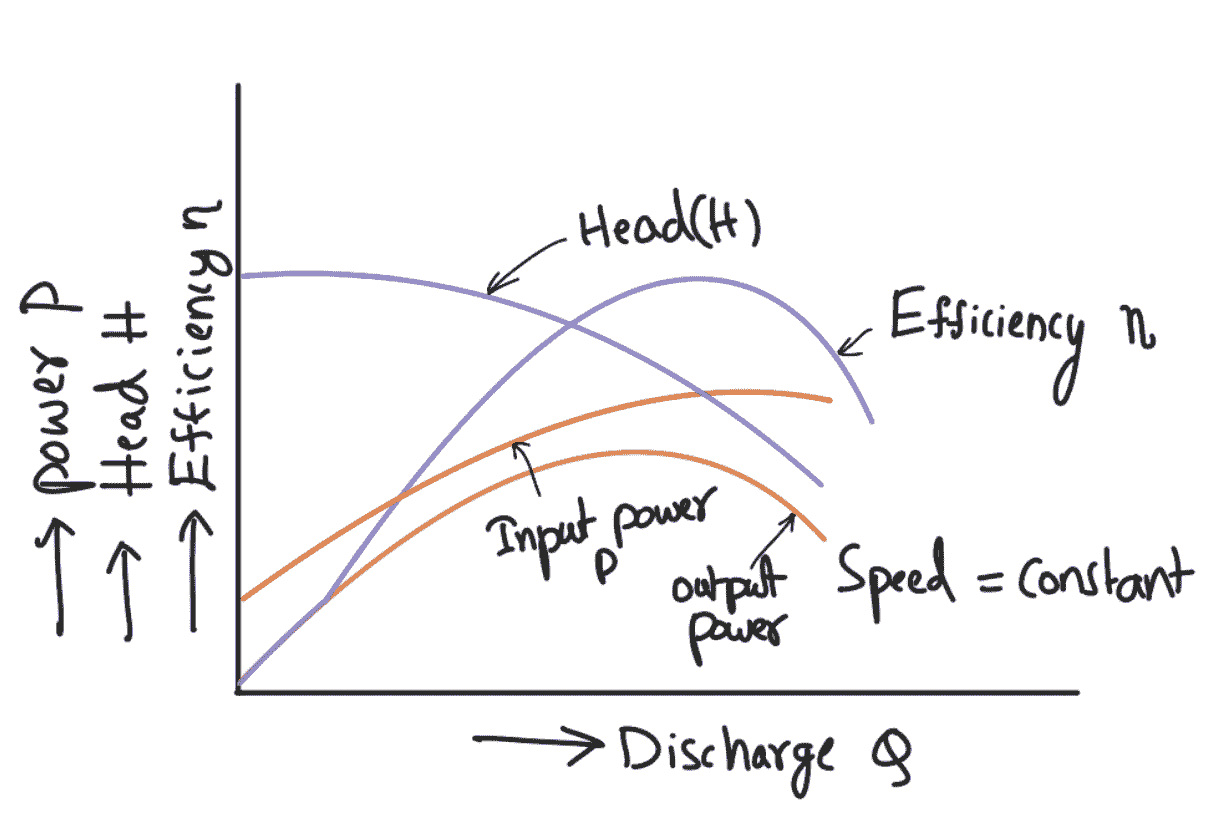

2. Operating Characteristic Curves

If the speed is kept constant, the variation of manometric head, power and efficiency with respect to discharge gives the operating characteristics of the pump. The following graph shows the operating characteristic curves of a pump.

The input power curve for pumps shall not pass through the origin. It will be slightly away from the origin on the y-axis, as even at zero discharge some power is needed to overcome mechanical losses.

The head curve will have a maximum value of head when discharge is zero.

The output power curve will start from the origin as at Q = 0, output power (ρ QgH) will be zero.

The efficiency curve will start from the origin as at Q = 0, η = 0

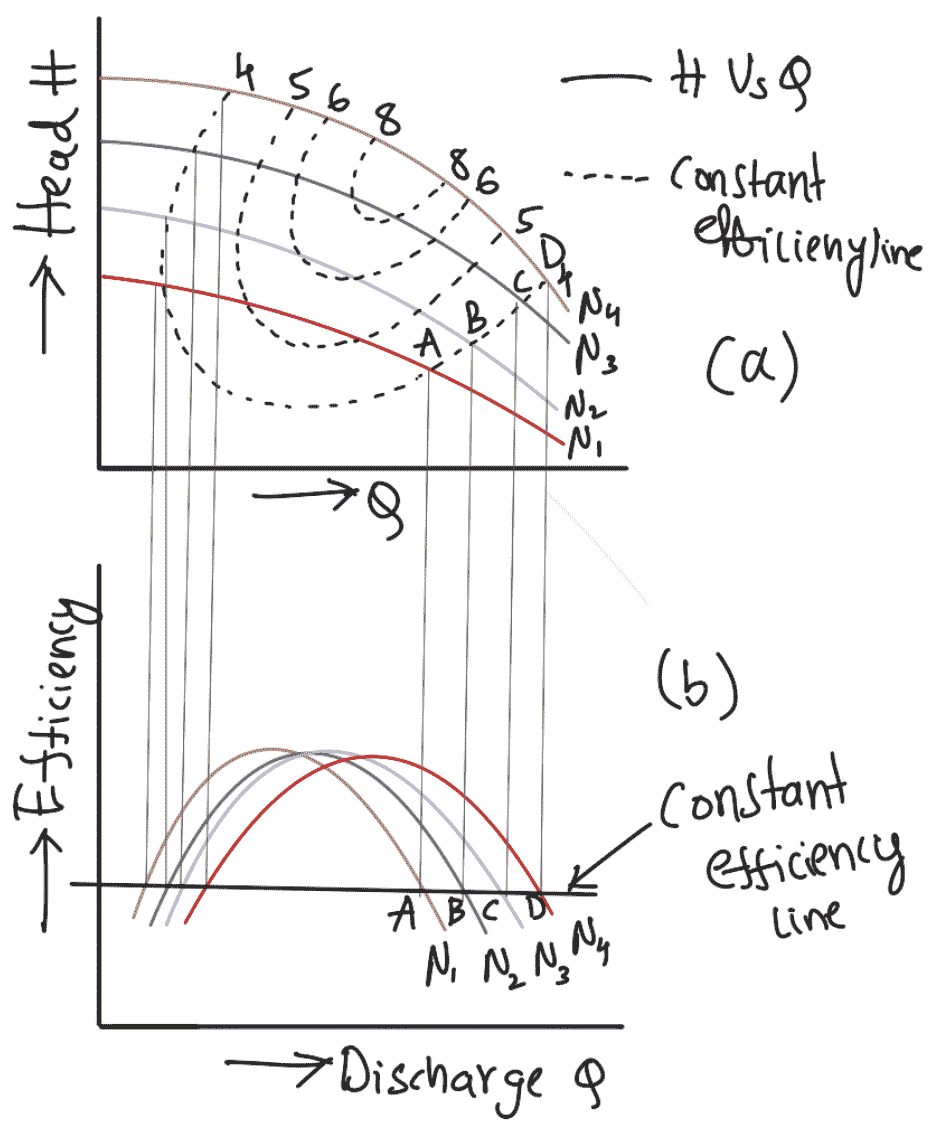

3. Constant Efficiency Curves

For obtaining constant efficiency curves for a pump, the head versus discharge curves and efficiency versus discharge curves for different speeds are used. The below graph (a) shows the head versus discharge curves for different speeds. The efficiency versus discharge curves for the different speeds is shown in graph (b). By combining these curves (H ~ Q curves and η ~ Q curves), constant efficiency curves are obtained as shown in graph (a).

For plotting the constant efficiency curves (also known as iso-efficiency curves), horizontal lines representing constant efficiencies are drawn on the η ~ O curves. The points, at which these lines cut the efficiency curves at various speeds, are transferred to the corresponding H ~ Q curves. The points having the same efficiency are then joined by smooth curves. These smooth curves represent the iso-efficiency curves.

Do you know what is Priming of a Centrifugal Pump is?

Priming of a centrifugal pump is defined as the operation in which the suction pipe, casing of the pump and a portion of the delivery pipe up to the delivery valve are completely filled up from the outside source with the liquid to be raised by the pump before starting the pump. Thus the air from these parts of the pump is removed and these parts are filled with the liquid to be pumped. The work done by the impeller per unit weight of liquid per sec is known as the heat generated by the pump. Equation (a) from the previous article gives the head generated by the pump as =1/g Vw2 u2 metre. This equation is independent of the density of the liquid. This means that when the pump is running in the air, the head generated is in terms of metres of air. If the pump is primed with water, the head generated is same metre of water. But as the density of air is very low, the generated head of air in terms of equivalent metre of water head is negligible and hence the water may not be sucked from the pump. To avoid this difficulty, priming is necessary to start the centrifugal pump.

Leave a Reply