A brake is a device by means of which artificial frictional resistance is applied to a moving machine member, in order to retard or stop the motion of a machine. In the process of performing this function, the brake absorbs either the kinetic energy of the moving member or potential energy given up by objects being lowered by hoists, elevators, etc. Let us discuss how we can calculate the energy absorbed by a brake.

As we mentioned above that the brake is used to retard or stop the motion of a machine. This action is called Braking. In the process of braking, the brake absorbs either the kinetic energy of the moving member or potential energy given up by objects being lowered by hoists, elevators etc. The energy absorbed by brakes is dissipated in the form of heat. This heat is dissipated in the surrounding air (or water which is circulated through the passages in the brake drum) so that excessive heating of the brake lining does not take place.

The design or capacity of a brake depends upon the following factors :

- The unit pressure between the braking surfaces

- The coefficient of friction between the braking surfaces

- The peripheral velocity of the brake drum

- The projected area of the friction surfaces

- The ability of the brake to dissipate heat equivalent to the energy being absorbed.

The major functional difference between a clutch and a brake is that a clutch is used to keep the driving and driven member moving together, whereas brakes are used to stop a moving member or to control its speed.

Energy Absorbed by a Brake

The energy absorbed by a brake depends upon the type of motion of the moving body. The motion of a body may be either pure translation or pure rotation or a combination of both translation and rotation. The energy corresponding to these motions is kinetic energy. Let us consider these motions as follows :

- When the motion of the body is pure translation

- When the motion of the body is pure rotation

- When the motion of the body is a combination of translation and rotation

1. When the motion of the body is pure translation

Considerabodyofmass(m)movingwith a velocity v1 m / s. Let its velocity is reduced to v2 m / s by applying the brake. Therefore, the change in kinetic energy of the translating body or kinetic energy of translation,

E1 = (1/2) m ((v1)2-(v2)2)

This energy must be absorbed by the brake. If the moving body is stopped after applying the brakes, then v2 = 0, and

E1 = (1/2) m ((v1)2)

2. When the motion of the body is pure rotation

Considerabodyofmassmomentofinertia I (about a given axis) is rotating about that axis with an angular velocity ω1 rad / s. Let its angular velocity is reduced to ω2 rad / s after applying the brake. Therefore, the change in kinetic energy of the rotating body or kinetic energy of rotation,

E2 = (1/2) I ((ω1)2-(ω2)2)

This energy must be absorbed by the brake. If the rotating body is stopped after applying the brakes, then ω2 = 0, and

E2 = (1/2) m ((ω1)2)

3. When the motion of the body is a combination of translation and rotation

Consider a body having both linear and angular motions, e.g. in the locomotive driving wheels and wheels of a moving car. In such cases, the total kinetic energy of the body is equal to the sum of the kinetic energies of translation and rotation.

∴ Total kinetic energy to be absorbed by the brake,

E = E1 + E2

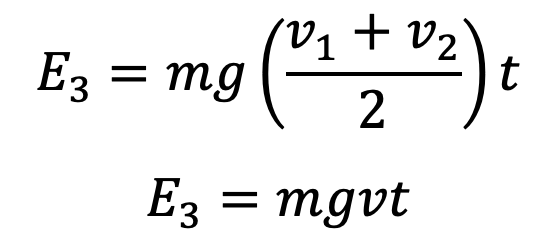

Sometimes, the brake has to absorb the potential energy given up by objects being lowered by hoists, elevators etc. Consider a body of mass m is being lowered from a height h1 to h2 by applying the brake. Therefore the change in potential energy,

E3 = m.g(h1 –h2)

If v1 and v2 m / s are the velocities of the mass before and after the brake is applied, then the change in potential energy is given by

Where

v = Mean velocity = (v1 + v2)/2

t = time of brake application

Thus, the total energy to be absorbed by the brake,

E = E1 + E2 + E3

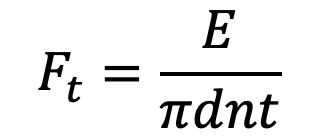

Let

Ft = Tangential braking force or frictional force acting tangentially at the contact surface of the brake drum,

D = Diameter of the brake drum,

N1 = Speed of the brake drum before the brake is applied,

N2 = Speed of the brake drum after the brake is applied

N = Mean speed of the brake drum (N1 + N2)/2

We know that the work done by the braking or frictional force in time t seconds

= Ft × π d N × t

Since the total energy to be absorbed by the brake must be equal to the wordone by the frictional force, therefore

E = F × π d N × t

or

The magnitude of Ft depends upon the final velocity (v2) and on the braking time (t). Its value is maximum when v2 = 0, i.e. when the load comes to rest finally.

We know that the torque which must be absorbed by the brake,

T = F × r

T = F × (d/2)

where

r = Radius of the brake drum

This is how we can Calculate the Energy Absorbed by a Brake. Let us know what you think about this article in the comment section below.

Let us also discuss the different material characteristics for Brake Lining.

Materials for Brake Lining

The material used for the brake lining should have the following characteristics:

- It should have high coefficient of friction with minimum fading. In other words, the coefficient of friction should remain constant over the entire surface with change in temperature.

- It should have low wear rate.

- It should have high heat resistance.

- It should have high heat dissipation capacity.

- It should have low coefficient of thermal expansion.

- It should have adequate mechanical strength.

- It should not be affected by moisture and oil.

The materials commonly used for facing or lining of brakes and their properties are shown in the following table.

| Material for braking lining | Coefficient of friction ( μ ) | Allowable pressure (p) | ||

| Dry | Greasy | Lubricated | N/mm2 | |

| Cast iron on cast iron Bronze on cast iron Steel on cast iron Wood on cast iron Fibre on metal Cork on metal Leather on metal Wire asbestos on metal Asbestos blocks on metal Asbestos on metal Metal on cast iron | 0.15 – 0.2 – 0.20 – 0.30 0.20 – 0.35 – 0.35 0.3 – 0.5 0.35 – 0.5 0.40 – 0.48 – – | 0.06 – 0.10 0.05 – 0.10 0.07 – 0.12 0.08 – 0.12 0.10 – 0.20 0.25 – 0.30 0.15 – 0.20 0.25 – 0.30 0.25 – 0.30 – – | 0.05 – 0.10 0.05 – 0.10 0.06 – 0.10 – – 0.22 – 0.25 0.12 – 0.15 0.20 – 0.25 – 0.20 – 0.25 0.05 – 0.10 | 1.0 – 1.75 0.56 – 0.84 0.84 – 1.4 0.40 – 0.62 0.07 – 0.28 0.05 – 0.10 0.07 – 0.28 0.20 – 0.55 0.28 – 1.1 1.4 – 2.1 1.4 – 2.1 |

Leave a Reply